Curvilinear Tool Paths For Pocket Machining

Recognizing the limitations of traditional approaches to pocketing, mathematicians at The Boeing Company have developed a system for generating tool paths that are better suited to pocketing at high feed rates. The same tool paths have demonstrated their usefulness at lower feed rates as well.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

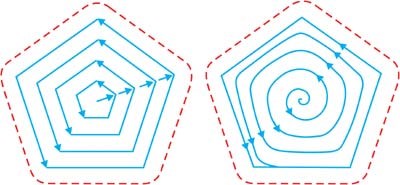

View MoreThe shape of a pocket tends to define the direction of its tool paths. The tool might move in back-and-forth passes that are parallel to one of the pocket's walls, for example. More commonly, the tool may begin at the center of the pocket and trace progressively larger versions of the pocket's precise shape until it reaches the final dimensions.

These approaches to pocket machining result in tool paths made up of straight lines and tight-radius corners. The corners exaggerate the influence of acceleration and deceleration on the total cycle time. While all of the cornering may not be significant at conventional feed rates, repeatedly slowing down for corners can dramatically reduce the efficiency of a pocketing operation that uses high speed machining. So why should the tool path be so beholden to the pocket's final shape?

Recognizing the limitations of traditional approaches to pocketing, mathematicians at The Boeing Company have developed a system for generating tool paths that are better suited to pocketing at high feed rates. The same tool paths have demonstrated their usefulness at lower feed rates as well.

To anyone familiar with aerospace machining, Boeing's interest in better pocketing will be obvious. Most aircraft structural members include multiple pockets, and the machining cycle for a structural member hogged out of a large billet can include dozens of pocketing operations. Pocketing is so common, in fact, that improving its efficiency could have a noticeable effect on the cost of the aircraft.

Michael Bieterman is one of the Boeing analysts who has been working on this problem. He presented the results of his work at a recent Society of Manufacturing Engineers conference on high speed machining. The application that he and colleague Donald Sandstrom developed generates pocketing tool paths that follow a gradually evolving spiral. The tool paths are curvilinear, following neither a circle nor a straight line. The path begins as a low-curvature spiral near the center of a given pocket, then progressively "morphs" toward the pocket's intended shape as the tool progresses outward toward the walls. With direction change occurring continuously instead of being concentrated at sharp corners, local acceleration and deceleration can be minimized.

In fact, the application that generates these tool paths can also optimize the feed rate. The tool path can be assigned a gradually varying feed that accounts for the machine tool's specific dynamic characteristics. (Accomplishing this involves an exercise in "trajectory optimization," says Mr. Bieterman, which is similar to what is required for flight control.)

The benefits of using the curvilinear paths have been demonstrated using test cutting and simulations. In aluminum, curvilinear cutting saves time. Comparisons with conventional paths for various pockets in aluminum show time savings on the order of 10 to 30 percent. (See table.)

In titanium, where slower feeds make cornering less of a concern, the curvilinear technique seems to deliver a different advantage—longer tool life. Comparison testing involving a 2-inch diameter tool run at 5 ipm in titanium actually showed a small increase in cycle time for the curvilinear path, but the payback for this extra time was an increase in tool life of nearly 100 percent.

At least part of the explanation for this probably lies with the fact that reduced cornering translates to a more consistent depth of cut, so the load on the tool is more steady. Based on this, Mr. Bieterman says it may also be reasonable to assume the curvilinear approach is less abusive to the machine as well—perhaps extending spindle life.

Boeing personnel are still working to improve the curvilinear application. Right now, there are restrictions that affect what pockets can be programmed this way. Meanwhile, a restriction of a different sort relates to access. At present, there is no easy way for a Boeing supplier, or any other contract shop, to take advantage of this technology. It probably won't see widespread use until a CAM supplier adopts it. For this reason, the aerospace company is considering licensing the technology to CAM vendors.

To contact Michael Bieterman, e-mail michael.bieterman@boeing.com.

Read Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)