Contouring Head Basics

Know how contouring boring heads work? If not, here’s a quick explanation.

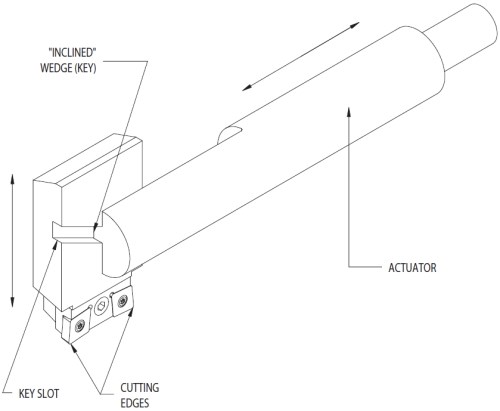

Machine-specific bonnets enable a single head to be used across a variety of boring mill brands. The bonnet bolts to a mill’s outer spindle (the outer spindle provides the rotation for the cutter). The contouring head quickly installs into the bonnet and is secured via locking cam pins. Other ZX heads, including modular boring tools and valve seat tools, can also be installed on a mill’s bonnet.

Related Content

-

Selecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

-

10 Ways Additive Manufacturing and Machining Go Together and Affect One Another

Forget “additive versus subtractive.” Machining and metal additive manufacturing are interconnected, and enhance the possibilities for one another. Here is a look at just some of the ways additive and machining interrelate right now.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.