CNC Shop Employees Benefit from Robotic Automation

To better use machine operators’ time and improve overall productivity, Dimension Machine Co., invested in two Okuma Genos lathes with a FANUC M-710iC/50 robot from Gosiger Automation.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View MoreFor Dimension Machine Co., a small company with limited resources, implementing robotic automation was a major step. “Frankly, I was more than a little concerned when we began the process,” says Ruthie Brockman, a machinist who helps manage production at Dimension. However, after working with Gosiger Automation (Dayton, Ohio) to implement two Okuma lathes tended by a FANUC robot, Ms. Brockman was pleased to find that the company produces 47 percent more parts per hour while better using its operators’ time.

Don Barth, owner of Dimension Machine Co., had long considered using robots to increase productivity in his 12-person shop in Cincinnati, Ohio. Dimension runs thousands of parts on 20 Okuma CNC machines. This enables the company to provide fast turnaround of quality parts to a variety of industries including transportation, OEM special machinery and forestry products.

Always interested in applying new technology to better serve his customers, Mr. Barth investigated robotic automation at the International Manufacturing Technology Show (IMTS). After visiting another plant to see it in a real-world situation, Mr. Barth searched for opportunities to apply robotic automation to Dimension’s operations.

He and his daughter, Ms. Brockman, initially decided to add a robot to service an existing Okuma LT-300 lathe that was already producing a large number of parts for the shop. However, after contacting Gosiger Inc. Sales Engineer Dave Marsh for a proposal, Mr. Marsh and his colleague, Greg Feix from Gosiger Automation, concluded that this plan might not be the best fit for Dimension’s needs.

Instead, Mr. Marsh strategized with the shop’s team, including key employee Dan Hutchinson, to get to the root of what must be accomplished. Mr. Hutchinson suggested that the company might need to automate two lathes instead of one in order to further increase production.

“Once we understood the advantages of the two-machine setup, we realized it was the best solution,” Ms. Brockman says.

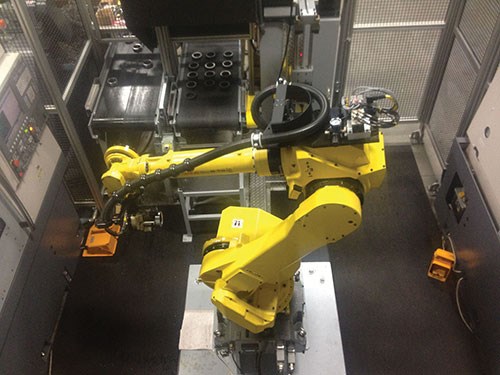

The arrangement Dimension selected uses two Okuma Genos lathes that face each other and a FANUC M-710iC/50 robot positioned between the two machines. The robot uses two, three-jaw gripper units to load and unload two parts at a time. It has a 50-kg payload capacity that includes parts and end-of-arm tooling, and a reach of 2,050 mm.

The design also includes a dynamic part turnover device that flips parts between operations. This device has a pneumatic gripper mounted on a pneumatic cylinder. During the turnover process, the pneumatic cylinder extends, and the robot “hands” the part off to the turnover device. The pneumatic cylinder lowers the gripper and sets down the part. Then, the robot picks up the part and repositions it in front of the machine for loading.

Two fixtureless, powered, flat-belt conveyors transport raw parts to the robot for processing, and they move completed parts to a manual unloading station. The system uses FANUC’s iRvision function to eliminate the need for a fixtured conveyor and reduce system change-over time. The robot operation area is enclosed with perimeter guards for worker safety.

One of the main reasons for adding the robot was to reduce manual loading and unloading of parts, which tied up the machine operator and kept that person from doing more productive things. Ms. Brockman knows first-hand that the 1.5-minute cycle times involved repetitious and tiring work since it was one of the tasks she did when she first started working at Dimension.

“Obviously this is a gross underutilization of the kind of person we want working here,” she says. “That’s why our first thought was to simply add the robot to the LT-300 lathe.”

With the two-machine setup, the operator’s time is now spent on more important tasks, including managing the flow of raw and finished parts. Using just one part the company manufactures—spacers—as an example, the new setup increased production from 90 parts in 9 hours to 150 parts in just 8 hours. “That means we’re making 19 to 20 parts per hour instead of 10, with no overtime,” Ms. Brockman says. As an added benefit, the robot’s efficiency has enabled the company to justify using a more expensive material that is far easier to machine.

As Dimension went through the process of installing robotic automation, Ms. Brockman says she realized that automating production of part families makes a lot of sense. In the example above, the company makes several spacers with ODs ranging from 3 to 3.5 inches and seal rings ranging from 3.5 to 7.75 inches. The cell is also running small bearing housings that weigh 20 pounds, along with jam nuts and tapped bushings. Dimension is in the process of adding some additional parts, including a 9.5-inch part and a 3.5-inch part that is 5 inches long. With this diverse range, Ms. Brockman says having the easy-to-program robot and the Okuma control makes it faster and easier to change over jobs.

Part of Ms. Brockman’s satisfaction with the end result was the reassurance and “handholding” the shop received from Gosiger’s training staff. This helped build her confidence in the new project. “In one day, I got over my concerns about operating the robot and decided it was the greatest thing on Earth,” she says. There were some bumps in the road, she admits, but Gosiger took care of everything and worked with Dimension to make sure the shop had what it needed.

In fact, using the robot is now so easy for Ms. Brockman, that when a group of high school students visited the facility for National Manufacturing Day, she was able to show them how the system works and actually let them use the control to make parts.

“I love what I do, and adding the robot to our shop has been really exciting,” Ms. Brockman says. “It’s also helped us to reexamine all of our processes to look for more ways to improve our operations, serve our customers better and enable our employees to be more productive while freeing them from repetitive, mind-numbing tasks.”

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreInvesting in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read More3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More