CNC Multispindles: Are They For You

Multispindle machines are highly complex and highly productive machine tools. Justification for their use in shops is well known. Lately, however, successful integration of multispindle CNC is changing the justification equation for shops currently using CNC single spindles.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Kurt Manufacturing Company

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View MoreMultispindle manufacturing for small parts looks, at first glance, like a breakthrough in production output. It seems logical that a six-spindle machine should outperform single spindle units by producing five times the parts per minute. And, when multispindle machines are totally dedicated to production of a single part, multispindle units often have time left over to further increase their profitability by taking on more business without additional investment in equipment or operation-related costs. In these cases, the benefits that CNC technology brings to faster job changeover are significant.

Discussion should start with an examination of the principle and operation of multispindle machines. Then we can explore the potential for increases in profitability as we climb the evolutionary ladder from single-spindle, cam-driven machines to investment in CNC-controlled multispindle screw machines.

More Spindles, More Work

In a very rough analogy, the multispindle gains its speed in very much the same way the old Gatling gun was able to increase its firing time. There's even a rough physical similarity. A multispindle machine subdivides the typical single-spindle operation cycle into more individually controllable segments.

In both multis and single spindles, tool movement and timing are controlled by a system of cams, a stored CNC program that actuates servomotors, or by a parallel operating system that is effectivly a blend of the first two. In this parallel mode, movement of tools is controlled by a central clock that electronically emulates the mechanical function of the main camshft and actuates the tool slides individually through servomotors.

In the single-spindle setup, one tool moves to the stock, completes its operation, returns to its home position, and the remaining operations are carried out in the same way, one step at a time. Some systems allow up to four tools to cut simultaneously—two turning tools and an endworking tool at the main spindle, and a back-working tool at the subspindle.

Still, on a single spindle machine only one part is being worked on per cycle. Cycle time might easily be 15 seconds per part, or just under four parts per minute—factoring in the time to feed new stock for the next cycle. While providing the flexibility of comparatively lightning fast changeovers, in general, cycle times for a CNC machine are slower than cams.

Multispindle machines begin with three, five, six or eight pieces of barstock, each secured in its own collet and mounted on an indexing headstock. With tools controlled at each index station in X and Y axes, and the provision for end working tools operating in conjunction with a subspindle, work progresses continually on parts in all spindles as they index from station to station.

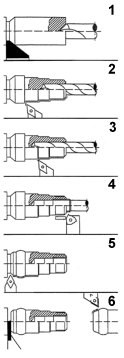

As the cycle time is reduced, the number of parts produced per minute climbs. With the ability to attack the work multiple times per cycle, usually parts can be fully completed on a multispindle machine (see Figure 1).

Step By Step

The option of mounting up to three tools at any one position, including one from the end, allows the programmer to break each operation into smaller components that may be carried out at different points in the multi-station cycle. A part might be drilled to an optimum depth to suit the timing of a parallel operation at that station, then drilled further at another station, and tapped at yet another point along the process.

As an example, we'll step through the 17-second cycle on the stainless steel part (see Figure 2). The cycle begins after the previous part is cut off at the sixth station. The machine is a Tornos MultiDECO 26/6, which is a six-spindle CNC machine.

The collet is opened and a new length of bar is fed in and locked; the entire barrel then indexes, in 0.8 second.

Position 1: A cross slide tool puts a chamfer on the back end of the part while a center drill, on the center slide, begins the drilling process with an oversize bit, just deep enough to create a chamfer at the beginning of what will be a threaded hole.

Position 2: The X2 cross slide, fitted with a turning tool, faces the part, then turns down a chamfer and three steps while the center slide, using a bit sized to the true hole diameter, feeds about two-thirds into the depth of the hole.

Position 3: The hole is drilled to its final depth and a turning tool finish-turns the two smaller diameters.

Position 4: The ID of the completed hole is now tapped and the slide moves a tool with an insert to single-point thread a portion of the OD of the first diameter.

Position 5: This position's tool finish-turns the largest of the three machined diameters and creates a radius on the original raw stock diameter, finishing it back to the largest diameter, leaving the appropriate length of the chamfer cut in position 1.

Position 6: The couterspindle collet grips the part as it is cut off from the bar, and the back end of the part is given its finish and a radius.

All of the cutters used in this cycle are standard insert tools. Part of the CNC multispindle economy derives from the ability to effectively use insert turning tools rather than form tooling.

Justifying CNC Multispindles

Why not just consider a cam-driven multispindle machine? They're cheaper, for one. Or simply purchase additional single-spindle CNC or cam machines?

Operator familiarity with CNC programming for screw machines is a major consideration. If your shop operates exclusively mechanical equipment, who will program a new CNC machine? On the other hand, today's tech graduates are used to the laboratory-like cleanliness and programming-based nature of the CNC environment and generally are not trained in the old cam methods. It's a dilemma for shops. One thing is for sure, the skill sets needed for the operation and setup of cam-actuated machines are increasingly in short supply.

Arthur Mandell is the machine tool finance and leasing principal of Trans Capital Resources Limited (Carlstadt, New Jersey), which has 25 years invested in consultation with companies working to justify their major equipment purchases. He stands firm in the belief that the only true measure of a machine's profitability to a company is based on the cost per part and the number of the parts run. "Ultimately," he says, "the production of the parts is what's going to pay the bill, driven by the cost per part. The least important part of the formula is the cost of the equipment.

"In theory," says Mr. Mandell, "one hundred percent of the parts that are made on a multispindle machine could be made on some other machine—but it doesn't work in reverse. So, clearly, one kind of consideration is the types of parts you're making." He cites the example of male-female relationship parts, where multispindles outpace single-spindle machines in the ease and time of switching over from male to female for a partial run.

Even were there is no direct cost advantage per part produced, there would still be the time advantage, allowing the multispindle machine to begin to produce parts sooner than on a cam-operated multispindle. Certainly, when cam-driven multispindle machines were the only option, the time to set them up was rarely justified by their faster cycle time over single-spindle cam machines. And, as with most high technology-based products, the cost of multispindle centers has begun to decline somewhat.

Run The Numbers

Mr. Mandell, firm in his position that the cost per part tells all, regardless of machine cost, prepared a cost analysis to prove it. The equipment cost comparison chart (see Figure 3) shows not only the economy achieved by using a multispindle machine, it makes several points that go beyond economy to generate additional business and realize a disproportionately greater profit.

The premise of the chart is the difference between two single-spindle CNC-controlled machines and one CNC multispindle machine. While the multi costs $200,000 more and runs for the same number of production hours per week, the values begin to change when cycle times are compared. As the single turns out a part every 17.5 seconds, the six-spindle multi, because it performs at least six operations at a time, drops a part into the bin every 4 seconds; that's 3.43 parts per minute for a single, 15 for the multi.

Assuming a reasonable 85 percent efficiency for both types of machines, it will require two single-spindle machines to turn out the projected two million parts, versus 0.45 multispindle machines. Essentially, the multi is working less than half-time to produce the same as two singles. Remember that for later.

Mr. Mandell's example is based on 8 percent financing for a five-year period. While the monthly payment for the two singles is $5069.10 less than for the multi, a reduction of that cost to parts per minute, considering machine cost alone, puts the singles at $0.051, while the multi—working only half-time—came in at $0033. The additional profit realized from the reduced cycle time: $34,351.32.

The real bombshell comes in the "Other cost factors per machine per period," in this case, five years. Using a base overhead of $2.00 per machine, the doubling factor of the singles begins to add up already, and continues through labor, maintenance and repairs (which assumes a one-year manufacturer's warranty). Now, in addition to more than $34,000 of increased profit, our hypothetical shop owner saves $623,400 in additional expenses—plus $171,756.58 in potential additional profit from the other 55 percent of the multispindle machine's available production time.

Here's where a moderately aggressive shop owner can more than double profit from his or her investment in multispindle technology. Better yet, the shop can bid more aggressively, due to open time on a machine that's already turning a profit at 45 percent of capacity.

It takes little risk to grow business that way, yet many people still look at that big dollar-figure investment in a multispindle machine and fail to realize the cost-per-part savings that can accrue to those types of screw machine shop business styles that lend themselves to the multispindles' advantages.

Is A Multispindle Right For You?

Dividing screw machine shops into three categories can help that decision along. Consider the differences between a job shop, a multi-customer contract manufacturer, and a contract manufacturer whose output is dedicated to single-part production all year long.

The job shop owner responds to whatever variety of purchase orders cross his desk on any given day. He knows that he has a certain number of customers, but doesn't know what their parts requirements will be. This shop is not a likely candidate for multispindle operation. That said, it is possible that the shop specializes in parts particularly suited to multispindle manufacturing, as in the male/female example cited earlier. It would take a very sharp cost analysis to see whether the investment would turn a greater profit, but if it did, it would open a strong competitive advantage. Having a mixture of equipment to handle the next job coming in, cutting changeover time might help to expand the business, but there is greater risk here than in other situations.

The contract manufacturer knows that he already has orders for certain quantities of certain parts, so he will be making the same or similar parts over time. Making time for cost comparisons of multispindle machines against existing equipment is highly warranted in this scenario. The shop has already specialized in a line of parts, and the continuing business for the duration of the contracts allows for a much greater sense of security in making the multispindle change. Since the multispindle cost per part advantage almost automatically creates a greater profit with the machines running at only half capacity, this company can aggressively pursue more work—or simply purchase fewer CNC multispindle machines and reap the profit inherent in the faster cycle and changeover times.

Then there's the contract manufacturer whose equipment is at 100 percent capacity all year, making the same part, time after time, perhaps on a single-spindle CNC or a gang of cam-driven machines. If we're dealing in quantities of six million identical parts, it's even possible that a rotary transfer system has been set up. But, come the time that this company eyes a juicy order for a family of parts in the one to two million range each, get a cost comparison like our example, and strongly consider expanding beyond the single-part business with a CNC multispindle or two.

About the author: Ernie Grohs is a product manager for Tornos Technologies, U.S. Corporation (Brookfield, Connecticut).

Related Content

3 Tips to Accelerate Production on Swiss Lathes with Micro Tools

Low RPM lathes can cause tool breakage and prevent you from achieving proper SFM, but live tooling can provide an economical solution for these problems that can accelerate production.

Read MoreDN Solutions Launches New Series of Turning Machines

The Puma DNT Series is equipped with a powerful spindle, a redesigned turret body and live tool drive that provide precise machining and productivity.

Read MoreInverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreRego-Fix’s Center for Machining Excellence Promotes Collaboration

The new space includes a showroom, office spaces and an auditorium that will enhance its work with its technical partners.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)