Clean Fire Suppression Protects Machines, Workers

Machine tool fires can cause unscheduled downtime, or worse, damage to the machine itself and possibly a shop’s facility. In fact, Siemens Building Technologies (Buffalo Grove, Illinois) says that more than 10 percent of all machine tools using non-hydrous coolants will have a fire incident within five years after installation.

Share

Autodesk, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View MoreMachine tool fires can cause unscheduled downtime, or worse, damage to the machine itself and possibly a shop’s facility. In fact, Siemens Building Technologies (Buffalo Grove, Illinois) says that more than 10 percent of all machine tools using non-hydrous coolants will have a fire incident within five years after installation. To help shops protect their machines, which often represent their largest, most important investments, the company offers a waterless fire suppression system that uses an environmentally safe extinguishing agent.

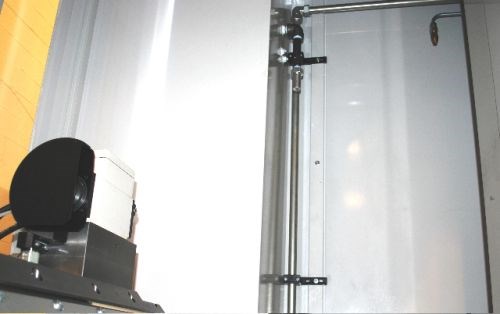

The Sinorix system is designed to quickly detect and extinguish fires resulting from the ignition of coolant, lubricating oil or other combustibles associated with machine tool operations. Marty Farraher, Siemens account executive, says the system can help shops maximize machine uptime and ensure worker safety in the event of an onboard fire. That’s because the suppressant, which is called Sinorix 227, leaves no harmful residue that could endanger workers or damage machine tool components and sensitive workpieces. With no messy cleanup, shops can bring machine tools back online within 24 hours after a fire by simply venting the work area and recharging the Sinorix cylinder, according to Mr.Farraher.

At the heart of the system are heat-detecting sensors mounted around the machine’s cutting area and mist-dispensing ducts. When ambient temperatures inside the machine exceed 135°F, the affected sensor sends a signal to an intelligent control panel that triggers the discharge sequence and stops the machine. Suppressant released under pressure through strategically positioned nozzles attacks the fire at the molecular level. By monitoring ambient temperature rather than the presence of actual flames, the sensors can detect slow-growing fires quickly before they escalate out of control, Mr. Farraher says.

The system can be activated in only two ways: via an electric signal when ambient temperatures reach the threshold or via the manual-release pull station. Combined with onboard condition monitoring and recording of relevant data, this prevents false alarms and accidental discharges, Mr.Farraher says. On activation, visual and audible alarms notify the operator of the fire incident. In addition to the local alarm, the system can be configured for remote monitoring or connected to the building’s fire alarm system.

Sinorix draws 120-V power from the plant supply but incorporates a battery backup in case of a power outage. It is available as original equipment for machine tool builders or for retrofit on existing machines. The company provides suppressant cylinder refill services at regional offices throughout the country as well as installation and system training.