Just This Once, You Can Blame the Gage

Even the old, reliable gage is subject to wear. George Schuetz, director of precision gages at Mahr inc., gives guidance for machinists to maintain their gages.

Share

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

For a change of pace this month, rather than advising those who use dimensional gages to not blame the gage when measurements are incorrect, I am going to address the times when one can blame the gage. The gage can be wrong, or perhaps I should say, a gage can go wrong.

One way that a gage can go wrong is through wear, and this is something that we are all inclined to overlook. This is likely because most users have come to think of the gage as a constant, like the mountains far off in the distance. Still, even the mountains will wear down with time.

How often does a machinist zero-check a micrometer for wear? How often does a machinist use an optical flat to check the anvils for flatness and parallelism?

Remember that the gage becomes the verifier of the print, the final word on the job, as far as the operator is concerned. Take a fixed-plug gage, for example. The print may say 1.2275 inches and the plug-gage handle may be similarly marked, but if the Go Gage is worn down to, say 1.2263 inches, the operator will give you 1.2263-inch holes.

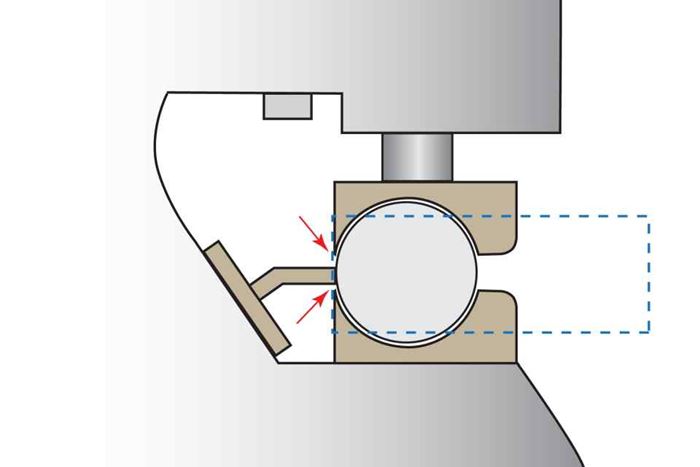

In the case of a micrometer or a comparator with parallel flat anvils, wear tricks us into a faulty measurement, which is illustrated in the exaggerated sketch shown in Figure 1. For example, if we set the comparator with a flat master, like a gage block, and then measure a cylindrical piece, error has been introduced.

How often should a gage be checked for wear? There is no single answer to this question. Many factors contribute to its wear: how many times it is used per week, month or year; the degree of hardness of the materials being tested; the kind of handling it receives; the frequency of repetition of a specific operation; and the conditions of cleanliness.

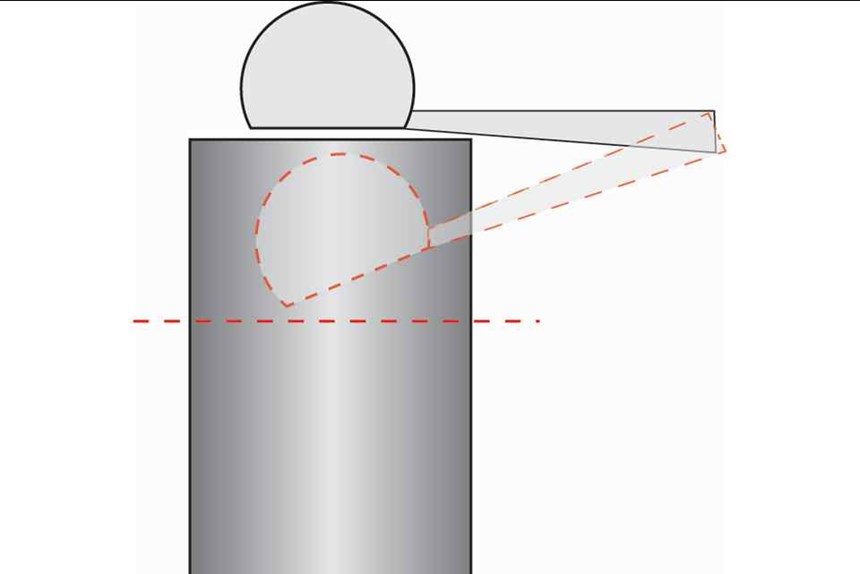

There are many situations in large-volume production in which gages are used as production tools. In such a setup, a gage may be measuring thousands of parts in a day. Contact with the parts always would be at the same place on the anvils or points. If the material being tested were very hard or abrasive, it would not be many weeks before the contact point on the gage would get worn down and accuracy would diminish (see Figure 2).

Of course, the material of the parts being checked must be considered when estimating the durability of your gage. It has been found that rough-cast iron, with its high silica content, is extremely abrasive and will wear down the hardest materials in a surprisingly short time. Cast aluminum parts will as well. Today, there are new materials like ceramics or especially hard materials that are designed for extreme wear being gaged. These characteristics must be taken into consideration when deciding on a wear-inspection protocol.

Conditions of cleanliness can be very important in reducing the amount of wear on a gage. It does not take much effort to imagine how much wear there might be on a micrometer used in a shop where there is abrasive dust in the air.

One should never forget that even the old reliable gage is subject to wear. It is imperative that the operator make it a habit to “check the checker” at regular intervals.

Related Content

Rethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

Read MoreSelecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read More4 Rules for Running a Successful Machine Shop

Take time to optimize your shop’s structure to effectively meet demand while causing the least amount of stress in the shop.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)