CAM Software Reduces Programming, Machining Times

MDL Europe needed a customizable CAM solution to program complex parts. Esprit CAM software from DP Technology proved easy to learn and increased production capabilities.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Producing large parts with precision and versatility required MDL Europe to make some necessary adaptations to address the changing needs of its customers and the increasing complexity of their parts. The company incorporated a new CAM programming system in its production process, as well as top-end machine tools such as large- and small-capacity CNC milling machines and machining centers with multiple kinematics. Together, these improvements increased its production capabilities and moved the company closer to its goal of being one of the market leaders in the global die industry.

MDL Europe, based in France, produces die holders, guidance systems, die sets, 3D prototype tooling and machining assemblies for toolmakers and machine manufacturers in the automotive, aviation and capital goods industries. Producing these parts, which are often large in size, requires high levels of machining precision and versatility, as the tooling frequently spans different product sectors. MDL has two production facilities in France, with additional manufacturing plants in Mexico, Brazil and India. Its production team consists of 45 specialists in three- and five-axis milling who are experts in high-speed machining.

In the past, MDL programmers worked with a closed-source software package that did not allow custom programming. The company says it also encountered coding errors for almost every part and was not confident running the programs.

To make full use of its robust machine tools and production machining specialists, MDL managers sought a global CAM solution that would be simple to implement and capable of automating the machining process. They found the solution they were looking for from an Esprit CAM software distributor, MHAC Technologies, located near Lyon, France.

“We quickly realized that Esprit from DP Technology met our programming needs, yet did not require a steep learning curve from our application engineers,” explains Vincent Bihr, MDL technical director. “In only a few days, MHAC installed the software, trained the programmers and generated the NC codes, thanks to certified postprocessors.”

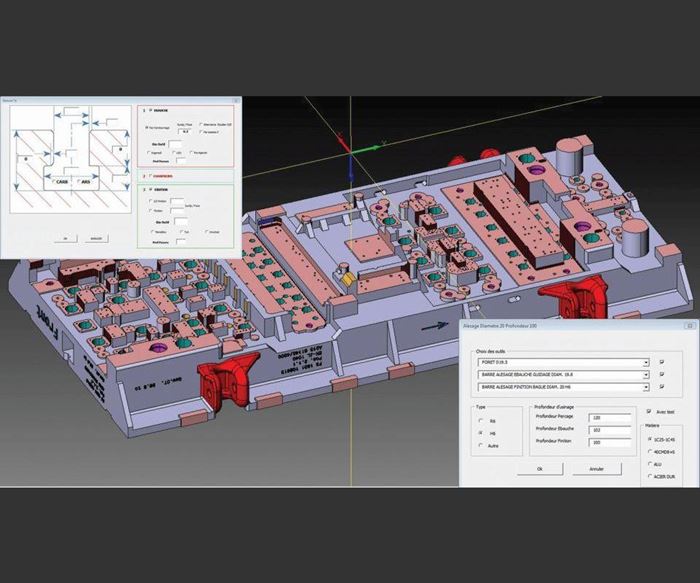

Programmers at MDL often deal with projects that require drilling, threading, reaming and pocketing plates. On these parts, the new CAM software reduced both programming and manufacturing times. Since the architecture of Esprit is entirely open, MDL was able to automate its machining processes using its application programming interface (API). The Esprit macros recognize the features being created in each CAD model. “For a die holder requiring 30 hours of work, we used to require 25 hours of programming. Using Esprit, programming now only represents 30 percent of the workload,” Mr. Bihr says.

During the manufacturing stage, the CAM software’s high-speed cutting strategy, ProfitMilling, improves rough milling, MDL says. Available with two, three, four or five axes, ProfitMilling is designed to optimize the angle of engagement, chip load, lateral cutting forces and the machine acceleration. At MDL, this cutting method helped reduce machining times by up to 40 percent on certain parts, it says.

The cost savings have been significant as well. When large-scale and delicate cast iron parts are being produced, a single error can have serious financial consequences. Esprit’s accurate and realistic simulation module helps MDL eliminate such potential manufacturing errors and their resulting cost. Patrick Willemann, head of CAM at MDL, explains: “We did not need to invest in separate simulation software. We make systematic use of the Esprit simulation module, which provides a faithful reproduction on the screen of what will happen on the machine. This helps avoid conflicting tool paths and broken tools.’’

MDL programmers are currently testing the latest generation of the Esprit software and have used it to create a 3D-milling pressure roller, starting with a raw cast. Previously, this type of part had to be programmed in several stages, but it can now be prepared in a single setup, which accelerates the implementation of the machining and manufacturing processes.

MHAC Technologies continues to help MDL optimize the use of its Esprit CAM software, in particular for the development of elite postprocessors and the implementation of specific software developments. “Whenever I have a question about Esprit, a technician contacts me the same day and can take control of my workstation to answer my question. We waste no time, and that is absolutely priceless,” Mr. Willemann says.

MDL decided to deploy Esprit CAM software throughout all of its manufacturing facilities after proven efficiency and consistent results were reported from its French production sites. The company plans to use its high-performance-manufacturing capabilities to improve part quality.

Related Content

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)