CAD/CAM Helps Aerospace Shop Machine Aluminum Guitars

Using CAD/CAM software from Matercam/CNC Software Inc. helped Wolfert’s Tool and Machine Co. develop and produce a single-billet aluminum guitar body.

Share

Autodesk, Inc.

Featured Content

View More

When Wolfert’s Tool and Machine Co. originally acquired advanced CAD/CAM capabilities for its St. James, Missouri, facility, the shop intended to use the software for making aerospace parts. However, when Owner Ken Wolfert wanted to make guitars from aluminum, the company realized the software would be well suited for the application. The company eventually developed an aluminum-body guitar, along with a company spinoff—the Metalin’ Guitar subsidiary—to market it.

The idea for the new product began in early 2011, when Mr. Wolfert was reading an article in a music magazine about how the hardwoods used in making solid electric guitar bodies were becoming endangered and would be depleted in the not-too-distant future. As a manufacturer of small aircraft parts made from aluminum billets, he wondered if guitars could be made in a similar fashion.

For instance, why couldn’t the same CNC machining technology be used to make single-billet guitar bodies, drive down manufacturing costs by machining them at high speeds with minimal setups, and offer buyers more value by giving them the option to customize the guitar with features and finishes of their own design?

Mr. Wolfert made some sketches, reminiscent of classic Les Paul models, and took them out to his shop where Plant Manager Dave Bast was writing CNC programs. Though he had little experience with guitars, Mr. Bast was confident in his ability to cut the complex mono-material part from aluminum.

Mr. Wolfert says his company never would have started this journey if it had not acquired advanced CAD/CAM capabilities several years earlier. At the time, the company was heavily engaged in making small aircraft parts for a Tier II supplier. Because Wolfert Tool was able to provide quality work and a fast turnaround, it was rewarded with increasingly complex work. Customers would often request aircraft parts with certain complex angles or ask Mr. Bast to create and undercut a critical component. Using a four-axis CNC machining center’s conversational programming, he would get the job done; however, this semi-automatic programming was very labor intensive and the workload was becoming a burden.

In 2008, Mr. Wolfert and Mr. Bast selected Mastercam CAD/CAM software from CNC Software Inc. (Tolland, Connecticut) to address this issue. With advanced CAD/CAM capabilities in place, and as-needed guidance from Mastercam reseller QTE Manufacturing Solutions, Wolfert Tool’s sales doubled over the next five years. During this time, personnel increased by only 50 percent—from 10 to 15 people.

This improvement in productivity and profitability made it possible for the company to keep pace with its growing aerospace workload and still have the capacity to diversify into promising custom-manufacturing ventures like making guitars.

According to Mr. Wolfert, aluminum guitar bodies themselves are not unique—the uniqueness lies in how they are made. For instance, other companies make them in layers. A top and back layer with divisions inside are welded together with an outside seam before being ground and smoothed. Wolfert Tool chose to make a closed chamber body out of a single billet of aluminum to improve strength, tone and sustainability, he says.

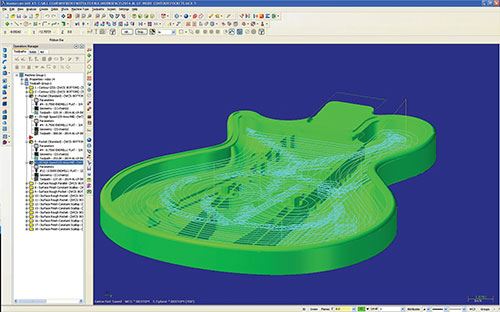

The first Metalin’ guitar body designs were made using Autodesk Inventor. These were readily imported into Mastercam, where the four-axis CNC cutting programs were generated. The design for the assembled product incorporated a solid graphite neck for weight reduction and a great feel, and Seymour Duncan pickups to improve sound quality, the company says.

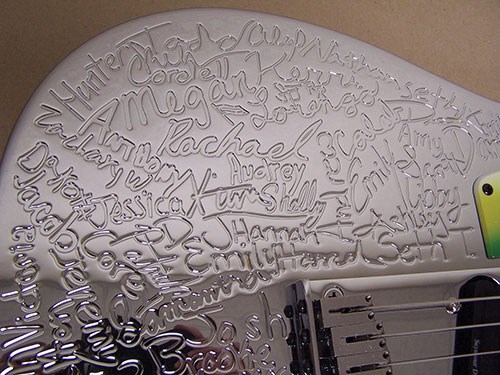

Mr. Wolfert originally conceived Metalin’ Guitars as one-off products with a fully customizable look that would be unique to each owner. But during the early design phases, he decided to also offer two off-the-shelf options that would be affordable for most serious guitarists. Mr. Bast modified the body design to make it easy and less expensive to add such options as an “f-hole” and a “whammy bar” without having to come up with new models to accommodate these add-ons.

According to Mr. Bast, Master-cam software made it easy to incorporate these changes in the CAM program. All he had to do was bring in the design changes and regenerate toolpaths, which automatically conformed themselves to the new geometry. This type of automation made it easy to move from one prototyping phase to another as changes were made to the model. During the early stages of prototyping, Mr. Bast produced eight different prototypes with solid-billet bodies.

Once they were satisfied with the prototypes’ structural integrity, sound quality and ease of play, the men began asking experienced musicians to try the guitars. According to the company, these users were surprised that a solid billet aluminum guitar body did not have a “tinny” sound and was a very serious instrument. There was one drawback, however. The guitars weighed 10.5 to 11 pounds, which is about 3 pounds more than the most popular electric guitar models. This would be a problem for players who might be practicing or up on a stage playing for hours at a time. This led to the next prototyping challenge—carving about 50 percent more material from the initial body designs without sacrificing structural integrity or musical quality. Mr. Bast was up for this challenge because many of the material removal approaches he had been using to achieve weight reduction in aerospace parts were readily adaptable to guitar bodies.

“A lot of aerospace parts are thin-walled structures,” he says. “For these, we have been using Mastercam’s Dynamic Motion technology that continually adjusts feeds and speeds to constant load on the tool and the wall of the part. This enables me to use a smaller tool, so that I can both rough and finish as I step down an interior structure inside the guitar body. With this approach, I can thin out these structures without distorting them so the body loses weight without losing strength or tone quality.”

The next round of prototypes involved creating CNC programs that remove as much material as possible from seven of the eight original prototype bodies. Mr. Bast worked closely with Metalin’ Guitar’s luthier, Jeremy Tessaro, to ensure that structural changes for weight reduction did nothing but improve the sound of the instruments. Mr. Bast used Mastercam’s Dynamic Motion technology to create safe tool paths undercutting sidewalls and creating narrow ribs in interior sections. Typical wall thicknesses were approximately 0.050 inch, unless additional material was required to support such components as the bridge, pickups and a whammy bar on the guitar’s face. When cutting was complete, guitar bodies that started as solid 24-pound billets of aluminum now weighed a couple ounces short of 3 pounds. The total instrument weight is 7 pounds, 2 ounces—right in the ballpark with popular electric guitar models.

Mastercam’s CAD/CAM technology also helped with design. For instance, Metalin’s morph design has a unique swirling surface feature created with Mastercam’s Morph toolpath. It was designed for pocketing uniquely shaped surfaces without overloading the tool as it approaches bends in the path. This roughing toolpath produced such an interesting fine textured pattern that the company retained it for one of its off-the-shelf products.

Related Content

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreContinuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)