Bolt-On Productivity

Retrofitting an auxiliary pallet changer allowed this shop to get 'horizontal-like' production efficiency out of a vertical machining center.

Share

Being productive doesn't necessarily mean being complicated. Indeed, for most shops it works the other way around. The simpler solution is almost always the better solution, even when more highly engineered technology looks good on paper. What matters most is what works within the real-world context of a shop's existing technology, workload and people.

Or better said, what really matters is making the most of a shop's finite resources, both human and technical. Automating the process of work handling can have a dramatic impact on both. When people are freed from the immediate task of manually loading and unloading workpieces on the table of a machining center after each cycle, then the people and the machine become more productive.

When it comes to automation, however, the question for many shops is just how far to go. Our prior story highlighted one case where a fully automated, lightly attended cell of horizontal machining centers makes sense. But there are many other applications that may call simply for some quick-jaw-change vises mounted on a manual pallet. The right solution really depends on volumes, the required balance between production efficiency and flexibility, and of course, the available capital for investment.

Much of the work at Ellcon National (Greenville, South Carolina) is right in the middle. Historically, the company did the majority of its machining on vertical machining centers. Then higher volumes and the desire for three-sided machining capability ushered in a bank of horizontal machining centers for some parts. Most recently, the company has seen the need to increase productivity on parts whose production requirements seem to fall somewhere in between stand-alone VMCs and HMCs. For these parts, retrofitting an existing vertical machining center with an automatic pallet changer has produced exceptional results, and well could be a strong production model for the future. It's simple, flexible and remarkably productive.

Building Volume

Now at about $67 million in annual sales, Ellcon National's core business is manufacturing air and hand brakes for railroad cars, something the company has been doing for more than 85 years. Additional products have been added in more recent times including windows for light rail transit equipment and pneumatic discharge gates for dispensing bulk plastic pellets from railroad cars. All are manufactured in the two plants at Ellcon's Greenville headquarters facility that employs some 350 people, about 250 of whom are in manufacturing.

Ask just about anyone in manufacturing at Ellcon what the overriding objectives are and you'll get the same answer: "We're a sales-oriented company." What that means is that the company is loathe to turn down an order for an inability to meet a delivery requirement. It's a small world Ellcon serves, with just a handful of companies building railroad cars and several able competitors, so the ability to deliver is crucial to business success.

Complicating the issue is the rather surprising variety of product. "We're sort of a custom shop," says manufacturing manager Don Shepherd. That doesn't mean everything is built to order. Rather, many braking systems are offered in different configurations assembled from a variety of mostly standard parts. And, of course, a hot order is always going to require at least one part that isn't in stock. So broken setups are a frequent occurrence here, as are engineering revisions that force the shop to stay flexible.

At the same time, there is continual pressure to grow more efficient. One of the main issues at Ellcon bucks the trend that many companies have seen over the last decade. While lot sizes in plants continue to shrink elsewhere, here they are actually getting larger. That's mainly due to the company's strong growth over the last nine years, in which sales have roughly tripled. That's a remarkable achievement under any circumstance, but all the more impressive considering the mature railroad and transit car industry that Ellcon serves. Much of the company's growth has come from product line extensions, but the company has grown the volume of its traditional product sales as well.

So, according to the assistant to the manufacturing manager, Walter Rekowski, where 300 pieces might have been a typical lot ten years ago, today it might be 1,000. That increase in volume created significant pressure to become more efficient in part loading and unloading. Ellcon simply had to find ways to get more parts out every day.

Changing Pallets

Ellcon had grown accustomed to machining on pallets in the early 1990s when the first Mori Seiki MH-50 horizontal machining center was acquired. With that, a few select parts were moved onto tombstone fixtures, with substantial gains in productivity. Later, at the 1998 IMTS _ International Manufacturing Technology Show in Chicago, Mr. Rekowski and Mr. Shepherd went looking for a means to produce similar results on a VMC.

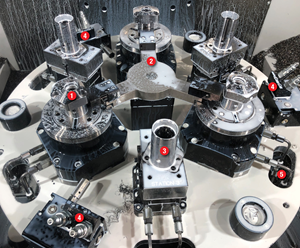

What they decided was to retrofit one of the shop's Mori Seiki MV 55 VMCs with a series 40SD automatic pallet changer from Midaco Corp. (Elk Grove Village, Illinois). The system consists of a low-profile pallet receiver, a side-mounted automatic shuttle unit, automatic enclosure door and two cast aluminum 40-by-19-inch pallets. The pallet receiver is permanently mounted on the table of the machine tool and is accessed through the side of the machine by the shuttle unit (rather than from the front of the machine, as manual pallet changers are typically configured). Once actuated via an M code in the part program, the enclosure door lifts, the pallet from the external loading station slides on guide rails into the machine and over the receiver and then drops down onto precision locating pins and is locked. Simultaneously, the internal pallet is unlocked, lifted off of its pins, and shuttled out to the loading station. The whole exchange of pallets takes less than 30 seconds. Once the exchange is complete and the internal pallet is locked down, the pallet changer control sends a signal to the CNC and the next cycle commences automatically.

The investment for the pallet changer was about $35,000, including installation, which was completed in a day. While that might sound like a lot of money for an accessory, it has been extremely easy to justify.

Justification And Payback

How did Ellcon justify the cost? In truth, the process was surprisingly simple. "We just look at the chip time," says Mr. Shepherd, "and for a two-year payback." That is, if the additional production time gained for the machine tool over a two-year period is worth more than the investment, then it is justified. Where Ellcon once evaluated production time in terms of labor rates, the more capital-intensive environment of today necessitates valuing machine time instead, based on average output per unit of cycle time. Moreover, with a shop average of one operator per two machine tools, and with machine tools growing more productive, labor is a significantly smaller percentage of the total production cost than it once was.

So, the critical distinction for justifying the pallet changer was not to keep people working but to keep the machine tool producing parts a higher percentage of the time. That lowers per-piece cost, adds real capacity to production and, of course, also increases output per unit of labor. According to Mr. Shepherd, this is why Ellcon chose to purchase an automatic pallet changer rather than a manual one. "The cost difference (between automatic and manual) isn't all that much. And with one person operating two machines, you just can't always be right there at the end of a cycle," he says. "That pallet change needs to happen whether the operator is present or not."

Ellcon's managers don't believe pallets are the answer for everything. But as the ratio of load time to cycle time grows larger, pallets grow increasingly attractive. As an example, Mr. Rekowski points to a gear hub part which is drilled and bored. "We used to put those gears in chucks (mounted on the table of a VMC) and machine them two at a time. The cycle time is only two and half minutes per part. But because of all the loading time, we were only able to average about 11 pieces an hour," he says. Now two pieces are loaded on quick-change fixtures mounted on pallets. With the average pallet change time of about 30 seconds, and all the part load/unload done off-line, average hourly production has increased 150 percent.

Another interesting example is the camming bar. Initially the part was held in a six-piece fixture, which was fixed to the table of a VMC. The cycle time was about 10.5 minutes for all six parts, but it would take another four to five minutes to unload and load parts between cycles. That was obviously unacceptable, so Ellcon's first task was to make three more fixtures and then mount all four on a tombstone for machining on an HMC. That slashed the internal load time down to one pallet change per 24 parts. Then when the Midaco pallet changer was installed, the parts were moved off the horizontal and back on to the VMC. Now, two fixtures are mounted on a pallet. While that has increased the internal load time somewhat—to one pallet change per 12 parts—it is still more than acceptable to Ellcon. Moreover, the parts are being machined on a platform that costs half as much as a horizontal, saving more HMC time for higher-value-added parts.

Overall, Mr. Shepherd says that Ellcon's experience with vertical pallet changing has exceeded his expectations, both in terms of time savings and in reliability of the new process. "You expect some problems with anything new, but we haven't really had any," he says. The one minor snag was a pallet that didn't seem to be seating properly, but that turned out to be a chip problem. Once the chips were cleaned, it worked fine. As for initial setup, that went pretty smoothly too. About the only things Ellcon had to change were the origin points in its part programs and the insertion of an M code. Otherwise, it was business as usual, only a lot more productive.

Related Content

Navigating Large-Scale CNC Machining: Suburban Tool’s Niche Strategy to Stay Competitive

Facing increasing competition from lower-cost imports, Suburban Tool made a move toward large-scale, in-house machining. By identifying a niche in large, precision angle plates and tombstones, the company has strengthened its ability to control quality and protect its reputation.

Read MoreShop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read MoreMachining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreCustom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)