Beyond Machine Monitoring

The networks of connected shopfloor devices that underlie implementations of data-driven manufacturing come together on many levels. Connecting machine tools to a monitoring system is just one of those levels.

Share

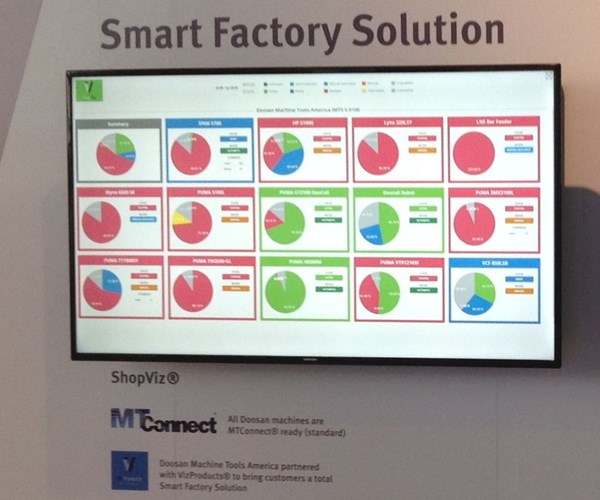

At IMTS, Doosan one of many exhibitors that had machines in the booth connected to a monitoring system.

I’ve been preaching that the value of data-driven manufacturing centers on making better decisions to improve manufacturing processes. What is propelling this movement is the capability of computer networks to gather data and make it available for analysis, reporting and archiving, followed by prompt, effective action on the shop floor. There was certainly lots of evidence of great progress and acceptance of this concept at the recent IMTS. In many booths, every machine on display was hooked up to a large screen showing its operational status, its recent activity and other vital statistics.

However, the frontiers of networking and connectivity in manufacturing are being explored and developed on many levels. For example, the data generators inside a machine must be carefully networked. One concept I saw at the show involves a modular control system that uses a localized network to connect sensors, gages and automated devices as nodes sharing a single communication cable. As a result, sensors on spindles, axis-drive bearings, lube systems and so on can be more efficiently monitored to keep tabs on machine health or refine predictive maintenance systems.

Likewise, better and easier connections between a machine and its auxiliary equipment boost productivity. The best example I saw consisted of a lathe, bar feeder, mist collector, chip conveyor, none of which came from the same supplier. Between each of these components, the interface uses MTConnect to share signals and data for virtually plug-and-play interoperability. A link to the scheduling system also enabled jobs in queue to be reshuffled automatically to make optimal use of the barstock and leave the shortest possible stub.

A similar development seems to be behind the surge in using robots to tend machine tools automatically. Exhibitors were showing the ease of programming the robot, interfacing it with multiple machines in a line and making it responsive to shifting production demands. This made applying robotic automation simple, flexible and affordable. In several cases, finding the necessary interfaces for grippers, pallet systems and conveyors is a matter of downloading an app.

Integrating scheduling software, enterprise resource planning and costing systems to a monitoring system is another level of connectivity to watch. At the show, I saw how shops can not only find out which machines are the busiest in making parts, but also which machines are producing the most profit.

.jpg;maxWidth=300;quality=90)