Behind the Curtain

Turnout for Mitsubishi EDM’s open house last week indicated a high level of interest in the company’s new line of Wire EDMs. However, despite being introduced with less fanfare, a few other new product lines shed light on the company’s future direction.

Share

ECi Software Solutions, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

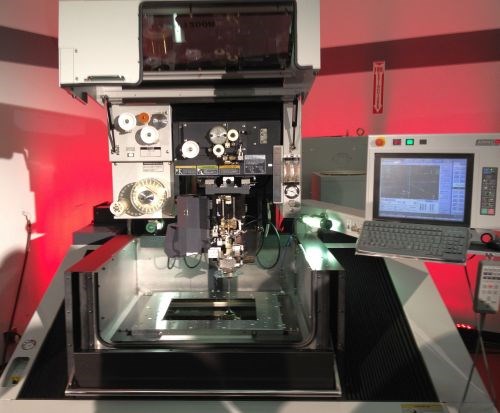

The MV series EDMs feature cylindrical linear shaft motors, a redesigned automatic wire rethreading system, an enhanced power supply and high-speed servo system communication, among other advances.

One of five different series of VMCs and drilling and tapping machines in the Diamond Cut general milling line, the DM series is said to excel in close-tolerance work and mold and die applications. Features include a 20,000-rpm, HSK-A63 spindle, a 32-position ATC, a Mitsubishi M720 CNC, linear scales, and roller guideways.

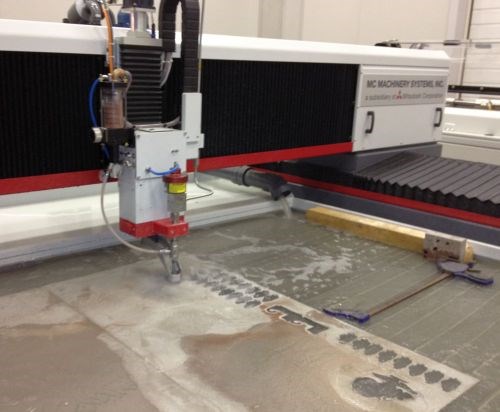

The company says the cantilever-style MWX3 waterjet is well-suited for production environments and new waterjet users. Notable features include a Mitsubishi 720 CNC and a 60,000-psi KMT pump.

If you weren’t able to attend the open house yourself, rest assured there will be plenty of other opportunities to see the MV series and other product lines up close. Most notably, the company will exhibit at both MFG4 May 8-10 and at the IMTS show in September.

.png;maxWidth=150)