Attributes of Manufacturing Leaders, Not Just Managers

A machine shop owner shares six attributes that good shop leaders have.

If my shop needs my 24-hour involvement to run effectively, then I have failed as a leader. Confident delegation of decision-making and Swiss CNC machining operations allows me to venture out to network, learn and promote our industry. If I succeed at finding qualified and motivated leaders from the limited (but growing) pool of skilled labor, I can spend more time on my business and less time working in it.

Nearly all of us have spent countless hours digging into “effective leadership.” We have taken classes, perhaps even hired a coach or attended a weekend retreat. We try to model the attributes of an effective leader as best we can. Technical competence and a willingness to control others simply are not enough. Someone might know everything there is to know about machining parts or the company’s enterprise resource planning (ERP) system, but it does not mean that person knows a thing about how to resolve conflict, show empathy or motivate others.

Twenty-five years as president and owner of Pioneer Service have taught me to set the bar high and to hold myself accountable for trying to meet effective leadership standards. Below are the standards and attributes I value most, but I realize that few people excel at all of them.

1. Leaders are committed to learning and adaptation.

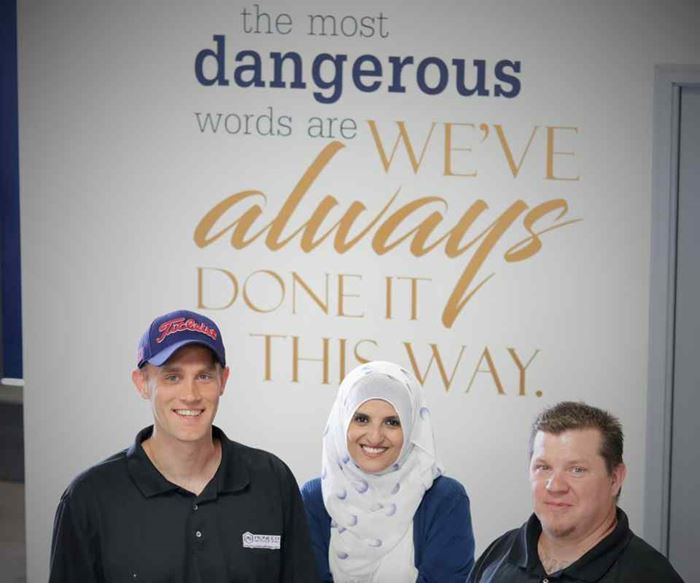

Humble leaders embrace continuous improvement and see it as a part of a symbiotic relationship with me. They identify gaps in technical expertise and people skills, and jump at training opportunities for themselves, their team and even their peers. Leaders acknowledge my willingness to invest in them, and they reciprocate by excitedly deploying those new skills to their position. It is no coincidence a sign in my shop reads, “The most dangerous words are ‘we’ve always done it this way.’”

2. Leaders hold others accountable, but they also accept responsibility for failures and share credit for successes.

Nothing evolves without risk. Egotistical leaders tend to be either mouselike or reckless with risk. Leaders with quiet, humble confidence know when to play it safe and when to push the envelope. They revisit their decision as necessary to accommodate changing agendas and keep their team updated and motivated, which allows these leaders to focus on high-payoff activities. Such updates do not necessarily require 30 minutes in a stuffy conference room, and quick “stand-ups” are often ideal.

3. Leaders are not perfect.

I have yet to encounter a form of learning that does not require a mistake. If I want my leaders to be committed to learning, then I must accept bad days. Things will break. Key performance indicators (KPIs) will sometimes dip. When leaders lose, they do not lose the lesson. They want to be a part of a winning team and find ways to make it happen.

4. Leaders are willing and able to make timely decisions…

even and especially when I am unavailable. Do not get me wrong: If there is a legitimate crisis, I want to be involved. However, a confident leader will be better equipped to handle more situations and often prevent those crises from happening in the first place.

5. Leaders excel at the soft skills as much, if not more, than the technical ones.

A discussion of “soft skills” would fill many volumes, but I believe “show respect, get respect” binds most of them together. Our company’s core values establish diversity as a strength, and strong leaders live by these same values every day. They give everyone a voice—women or men, veterans or millennials—and they refuse to play favorites.

Given a choice, I would rather promote someone with average technical skills and exceptional people skills into a leadership role, than vice-versa. Smart, motivated people can still be toxic. If I find someone with remarkable abilities in communication, expectation management and empathy, then I am more than willing to provide guidance in the tech.

6. Leaders “show” more than they “tell.”

Telling others what to do is a tiny part of the job, and leaders set the example by living it every day, especially when it is inconvenient or exhausting. Teams respond to leaders willing to get their hands dirty in the shop instead of just watching the clock. Teams also notice when leaders treat the company’s checkbook like their own, challenging suppliers to provide better pricing, faster delivery and more efficient tooling. In the end, it is about the customer, and the leader sets the pace through actions, not words.

As leaders, it falls to us to prove to our team that we hold their best interests at heart. This sometimes means accountability and a willingness to have uncomfortable conversations. Some employees are a dream, some are challenging and many fall somewhere in between. Whether about proper training, raises or reprimands, such leaders see these conversations as vital components of a winning effort. Anything else is a disservice to them, our customers and our industry.

About the Author

Aneesa Muthana

Aneesa Muthana is co-owner and president of Pioneer Service, a Certified Women-Owned Small Business specializing in Swiss screw machine products, CNC turned parts, and centerless grinding services in Addison, Illinois. Email amuthana@pioneerserviceinc.com or visit www.pioneerserviceinc.com.

Related Content

How to Pass the Job Interview as an Employer

Job interviews are a two-way street. Follow these tips to make a good impression on your potential future workforce.

Read MoreDN Solutions Responds to Labor Shortages, Reshoring, the Automotive Industry and More

At its first in-person DIMF since 2019, DN Solutions showcased a range of new technologies, from automation to machine tools to software. President WJ Kim explains how these products are responses to changes within the company and the manufacturing industry as a whole.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreRead Next

Increasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read MoreIMTS 2024: Trends & Takeaways From the Modern Machine Shop Editorial Team

The Modern Machine Shop editorial team highlights their takeaways from IMTS 2024 in a video recap.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)