Aligned for Precision

To precisely condition the form, shape and finish of an inside diameter of a workpiece, no machine tool outperforms an ID grinder if (and only if) key components of this grinder are properly aligned. This article outlines the importance of this alignment, explains how to recognize the symptoms of misalignment and describes what corrective steps to take.

Share

To precisely condition the form, shape and finish of an inside diameter of a workpiece, no machine tool outperforms an ID grinder if (and only if) key components of this grinder are properly aligned. This article outlines the importance of this alignment, explains how to recognize the symptoms of misalignment and describes what corrective steps to take. The author, Bill Bednarski, is an applications engineer at Saint-Gobain Abrasives in Worcester, Massachusetts.

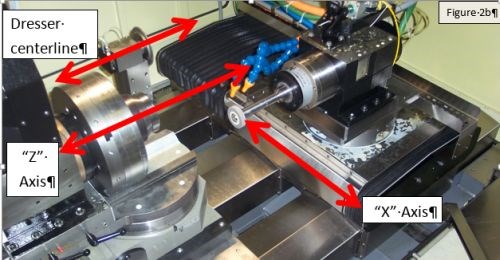

The components on a basic ID grinding machine that must always be in alignment are the X- and Z-axis slides, the grinding wheel spindle, the grinding wheel truing dressing device and the workhead spindle. As the linked article above shows, a properly aligned ID grinding machine, along with the right wheel specification and optimized grinding cycle parameters, will be a very cost-effective method to produce precision workpieces.

Related Content

-

Inside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.