After Grinding, What’s Left for Gear Hobbing, Shaping and Shaving?

With so many advances being made in gear grinding technology, where does that leave processes such as hobbing, shaping and shaving? This shop explains its machining methodology.

Share

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

Machining processes evolve over time, some to a greater extent than others. In gear manufacturing, grinding technology has shown particular growth, with advances in both machines and abrasives delivering more stability, greater material removal and longer tool life than ever before. In fact, with grinding machines now able to produce a gear straight from a blank all the way to a finished product, some shops no longer perform other traditional gear manufacturing processes, instead choosing to invest their time and capital in grinding machines alone.

So where does that leave well-known and long-used processes such as gear shaping, shaving and hobbing? How have these techniques improved over time, and what role do they play in the current approach to manufacturing gears?

Schafer Gear Works is an advocate of advanced grinding technologies, with a total of eight grinders available, including five fully automated Gleason machines. However, it still performs shaping, shaving and hobbing when one or more of these processes are called for in order to satisfy different customer requirements or prepare to minimize stock removal on their high-speed grinders. Due to this, Schafer still relies on these traditional processes for reasons having to do with materials, geometries and time.

Supporting those processes with new technology, workforce expertise and savvy process engineering has helped the company provide customers with greater latitude in terms of the qualities of the finished part as well as the cost based on the machining process chosen to produce the gear or part in question.

The Schafer Saga

Launched in 1934, Schafer Industries is headquartered in South Bend, Indiana, with additional manufacturing facilities in that same state as well as Ohio and Illinois. Bipin Doshi is CEO and president, while Stan Blenke is its executive vice president and CFO. Growth has been achieved through wise capital investments and the acquisition of other companies that fit into its strategic business plan for growth.

The company is divided between two divisions: Schafer Gear Works and Schafer Driveline. It is known as a manufacturer of precision gearing of all sizes in addition to axles, transaxles, transmissions, brake assemblies and other components for various transportation-related markets, which also include leisure and off-highway.

Two of the company’s facilities are devoted to manufacturing gears and each site has its own specialty. Small precision gears with tolerances ranging to 0.0002 inch for the aerospace and automotive industries are produced in Fort Wayne, Indiana, while medium-size spur and helical gears—as well as bevel and worm gears—are manufactured in South Bend. Large-diameter spur and helical gears (with grinding ranging to AGMA Class 12) up to 60 inches in diameter and face grinding as large as 8 inches in diameter that have traditionally been produced at the company’s Rockford, Illinois, facility will soon be machined in Roscoe due to Schafer’s recent acquisition of Custom Gear & Machine Inc.

The South Bend location performs all of the gear manufacturing processes listed so far, in addition to EDM and Swiss turning. Since Schafer is a high-production manufacturer, there is a great deal of automation and the work flow is laid out in such a way that each process naturally leads to the one that needs to occur next. In addition, most shop employees are cross-trained so they can operate multiple machines and/or cells, leading to a high degree of flexibility on the floor.

Processes and Purposes

According to Steve Fussell, manufacturing manager, the primary benefit of grinding for gear production has historically been the improved gear quality after heat treating to produce near-perfect symmetry and micro-finish, which results in very quiet gears. It is also necessary as a finishing process after many roughing operations. Nowadays, you can add increased material removal thanks to more powerful machines, the availability of automation and improved wheel grades. Schafer’s two newest Gleason grinders—a 160 TWG for gears as large as 160 mm in diameter, and a 200 GX which grinds gears ranging to 200 mm in diameter—are fully automated and meet quality standards of both ISO 9001:2008 and AGMA 11. So it’s clear that Schafer is taking full advantage of the latest in grinding technologies. But how about other traditional gear machining processes—when are they used, and why?

Hobbing—When it comes to aggressive material removal while machining spur and helical gears as well as pinions, hobbing is the gold standard, Mr. Fussell says. He describes the hob he uses as a fully coated, multi-start cutting tool that is cylindrical in shape with helical cutting teeth. These teeth have gashes along the length of the hob that aid in both cutting and chip removal. A specialized form of milling, hobbing can rough out gears at a speed that enables Schafer to produce a million gears a year quickly enough to avoid creating a backlog in the machining process (a significant number of Schafer’s gears are manufactured using the standard “hob, heat treat and finish” grind technique). At the same time, not everyone requires a super-fine surface finish like that produced for industries such as aerospace. In such cases where a fine finish is not required, perfectly functional pinions can be hobbed and then heat treated without finish grinding.

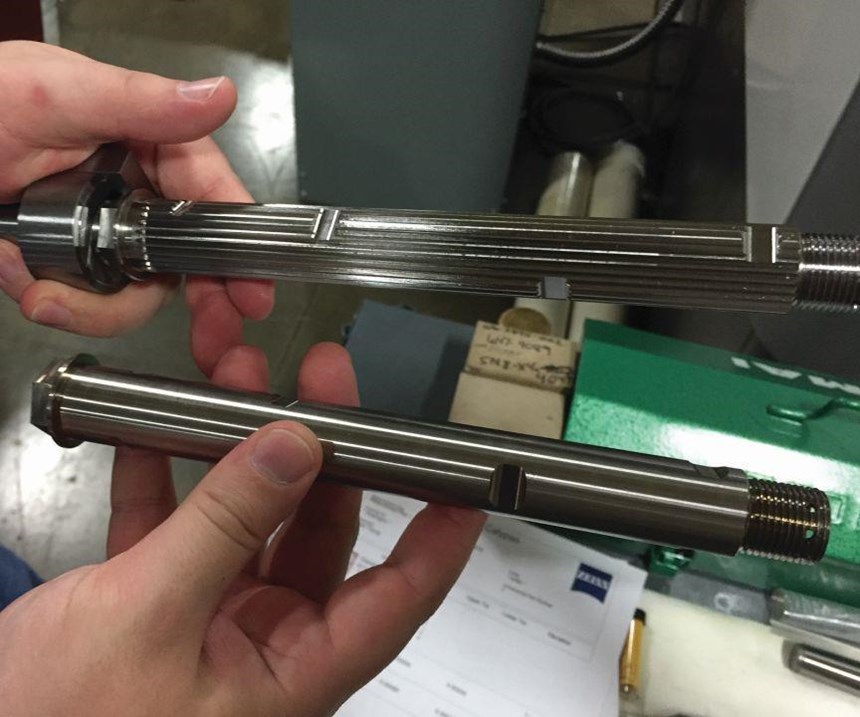

Schafer’s approach to harnessing the power of hobbing is to first equip each machine with automation so that a single operator can run as many as four machines. When hobbing is conducted properly, the accuracy is such that just 0.004 inch per flank of material is left to be removed after heat treat, which the grinders can handle in less than a 1-minute cycle on many parts. To meet its production goals, Schafer has 15 to 20 hobbers running at a time, primarily machining 8620, 4140 and 9310 alloy steels, as well as bronze and stainless steel. Some machines are equipped with a spline roller, which basically “crushes” the spline into the pinion shaft, and others have either automatic deburring machines in the cell or make use of an option to mount deburring tools directly onto the hobber.

Despite its many attributes, however, hobbing can’t be used to cut gear teeth with an adjacent shoulder due to the shape of the hob and clearance issues, Mr. Fussell points out. This is where shaping comes in.

Shaping—This machining process creates gear teeth by using a cutter that is applied to the workpiece in a continuous rotating movement along the same plane. The four basic types of cutters—disks, hubs, shanks and helical cutters—actually mimic the forms of the gears they’re used to produce. The cutter is located on one spindle and the workpiece revolves around the tool on another spindle in a reciprocating motion that duplicates the gear tooth form of the cutter. The process is used to produce internal gears, external gears and gear-pinion arrangements. It is also the only way to address the aforementioned situation when gear teeth are located near an adjacent shoulder, which no other process can produce competitively, resulting in a higher cost per part than other processes due to its somewhat complicated tooling.

Both machine tools and cutting tools have been greatly improved upon in recent years, Mr. Fussell says. Newer CNC shapers and machine tools enable operators to cut at higher strokes per minute and to run modified programs to minimize cycles. The cutting tools hold an edge much longer than they once did thanks to stronger materials and newly developed coatings.

Still, shaping is a slower process than hobbing, requiring creative ways of getting as many gears as possible across the machine. The solution, due to the limits of the process technology, involves training an operator to run multiple machines. With a total of eight shapers on hand in South Bend, Schafer has worked to train a single operator to oversee five or six running machines. The slightly slower cycle times are what make it possible for one operator to load and unload so many machines at once.

Shaving—Whereas shaping is a roughing operation, gear shaving is a finishing process that corrects errors in index, helical angle, tooth profile and eccentricity. It can remove the majority of the errors often found in hobbed or shaped gears. As its name implies, in shaving, the cutting tool rides across a gear’s surface and between its teeth to continuously remove tiny shavings of metal, providing a smooth surface finish and therefore quieter gear sets. The process also increases a gear’s load-carrying capacity as well as its service life, since a smooth surface protects the gear from spalling, and wear between mated parts is minimized.

The cutting tool used in rotary gear shaving operations is made of high-speed steels, hardened and ground. Factors affecting tool life include the condition of the parts coming off the hobber. Some shaving cutters can process as many as 4,000 gears between sharpenings, and they are generally resharpened about 10 times.

Remembering a time not that long ago when shavers were relatively rudimentary, Mr. Fussell says new CNC shavers show improvements both in their ease of use and their machining capabilities. Progressive diagonal cutting is another helpful process, which takes the approach of moving the cutter across the gear tooth, providing the operator with more versatility to make profile adjustments.

Continued Improvement

After a season of heavy investments, both in terms of capital equipment and business acquisitions, Schafer Gear Works plans to continue streamlining operations and learning about the latest technologies that will enable them to continue to prosper, add capabilities and enter new markets. According to Mr. Blenke, the company is generally making its strategic plans quite a few years in advance so they’ll be prepared for upcoming changes. Many of them have to do with investing in connectivity—a few of their Gleason machine tools are connected to the OEM’s service technicians at present, and Schafer's impression of the technology is highly favorable—improving quality control, as it recently did by purchasing a Gleason 300GMS P gear inspection system; and cross-training employees for a flexible and agile workforce.

Read Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)