A Virtual Jog Mode for CAM

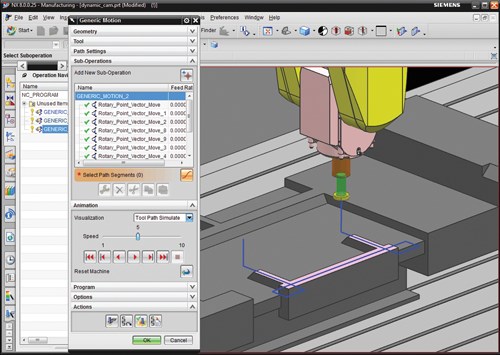

This CAM feature allows tool paths to be defined through a process that resembles jogging the machine manually.

Share

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

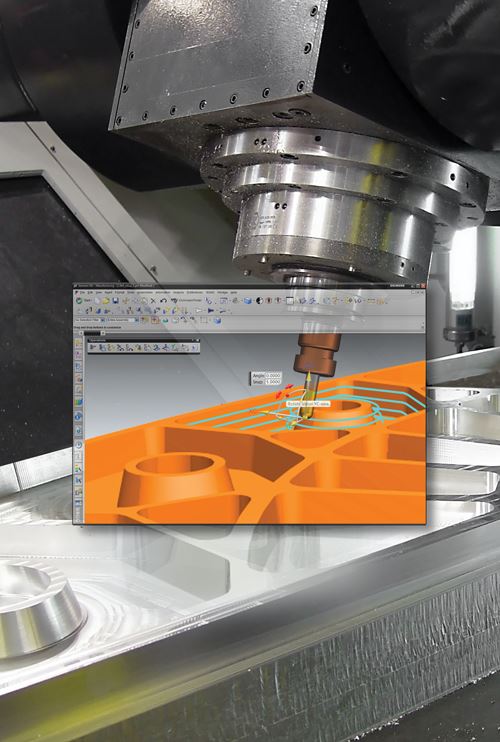

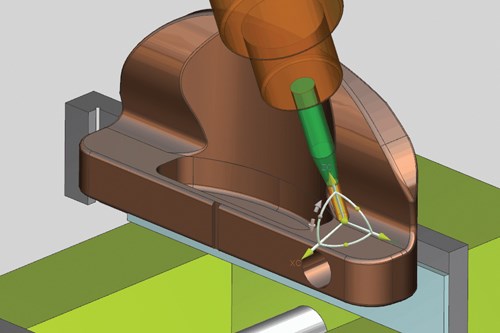

View MoreOnscreen graphical interaction with the cutting tool and part continues throughout the NX system. For example, to define a tool axis, the user positions the tool near the area to be cut and dynamically manipulates the handles attached to the tool display. For an interpolated tool axis option, the tool is shown at all four corners of the area to be cut along with dynamic handles. These handles can also be snapped to part geometry to preserve associativity.

Related Content

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)