A Clean Fire Prevention Alternative for Machine Tools

This environmentally friendly fire-extinguishing system does not lead to ozone depletion. Plus, it is said to be ten times more effective in extinguishing fires than halon.

Share

There are clear benefits to implementing unattended machining operations. There are obvious dangers, too, especially when oil-based coolants are used. These combustible coolants are susceptible to flash fires that can not only damage or destroy a shop’s machine tool, but can devastate an entire facility if left undetected.

On-machine fire suppression systems offer good insurance for costly equipment as well as peace of mind that any fire that might spark inside a turning center or mill will be quickly extinguished. These systems use some type of heat-sensing mechanism that automatically triggers the release of an extinguishing agent when a fire is detected inside a machine’s enclosure.

Unlike many agents that work by reducing a fire’s heat or oxygen levels, the Stat-X aerosol-based system from Fireaway (Minnetonka, Minnesota) chemically interferes with the “free radicals” that fuel flame propagation. (A free radical is an uncharged, often highly reactive molecule with an unpaired valence electron.) Although it functions similarly to halon, the environmentally friendly Stat-X system does not lead to ozone depletion. Plus, it is ten times more effective in extinguishing fires than halon, the company says.

The heart of the Stat-X system is a stainless steel aerosol generator that mounts inside a machine. When a fire is detected, the generator releases an aerosol stream containing fine particles of potassium compounds (1 to 2 microns in size) that bind with the fire’s free radicals to extinguish it. Because of the aerosol’s fine particle size and inherent buoyancy, it hangs in suspension within a machine’s enclosure for as long as 60 minutes. That enables easy venting by fan or air-handling system after discharge. Because the aerosol does not begin to “settle” for an extended period of time, only very minor amounts of particulate might be deposited on equipment. For clean up, one needs only to extract the aerosol and air out of the machine enclosure. The aerosol is non-toxic at normal concentration levels.

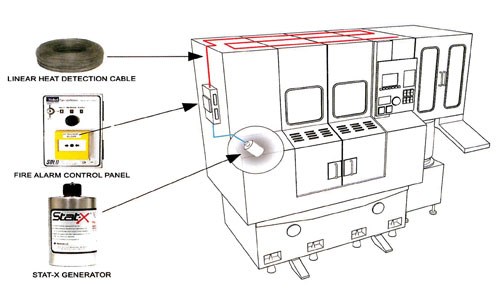

The company says Stat-X aerosol generators are affordable to install and maintain because they do not require the pressure vessels, piping or expensive setup costs associated with other extinguishing systems. There are two Stat-X versions for machine tools. One is an electrical system that is tied to a fire sensing device and an electrical releasing panel (this is depicted above). The canisters for these systems range in size from 30 grams (covering up to 0.5 cubic meters) to 2,500 grams (covering up to 40 cubic meters). Thermal systems, which have an integral detection mechanism inside the aerosol generator, are also available. These systems eliminate the need for the fire sensing device and releasing panel. They are geared toward smaller applications and use aerosol generators ranging in size from 30 grams (covering up to 0.5 cubic meters) to 500 grams (covering up to 8 cubic meters).

In addition to machine tools, Stat-X systems are useful for applications in telecommunications facilities, process control rooms, data processing facilities, flammable liquid storage areas, power plants, marine engine rooms and many others. Fireaway also offers manually actuated aerosol generators as well as First Responder units, which are small handheld devices with pull actuators designed to be tossed into rooms to provide immediate flame suppression.

Read Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)