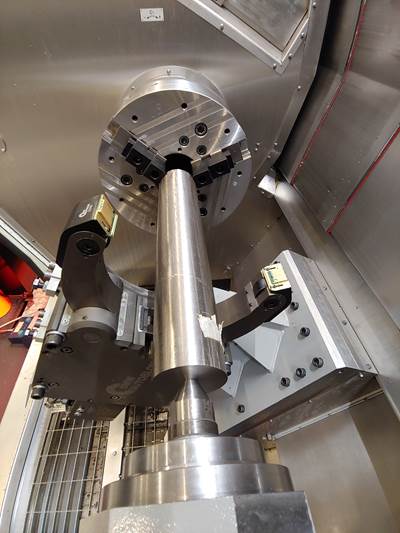

Turning Tools

Walter Cermet Turning Inserts Boost Stability

Walter’s indexable cermet turning inserts use the company’s FP2 geometry to reduce vibration, produce stronger corners and enhance surface finish.

Read MoreWhy Binderless CBN Inserts Turn Titanium Faster

A new formulation of cubic boron nitride could provide a more solid alternative to cemented carbide as finish-machining becomes more demanding.

Read More2021 Will Be Dramatic, Too — How Is Your Tooling?

The time is now to take stock of your tools. Recently posted articles explore the potential impact of tooling technology.

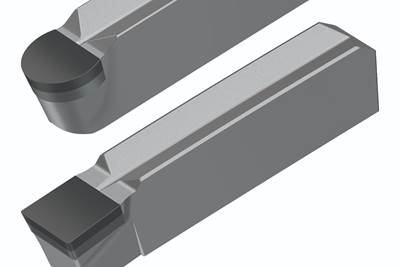

Read MoreWalter Increases Tool Life With ISO-H and ISO-S CBN Grades

Walter WBH20 and WBS10 grades provide improved quality, reliability and tool life in grooving operations on ISO-H and ISO-S materials, respectively.

Read MoreCutting Tool Technology Aids Lights-Out Machining Applications

These features can help improve cutting tool stability, standardize cutting performance and extend tool life, enabling shops to confidently run unattended shifts.

Read MoreQ&A: Trends in Cutting Tool Application

Cutting tool technology is advancing and shops’ needs are changing as well. A leading cutting tool supplier offers this view.

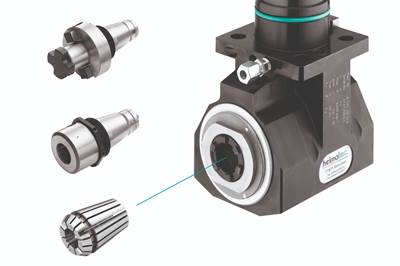

Read More4 Questions To Ask When Moving to Live Tooling

Live tooling is often seen as a niche solution, but there are a number of different processes that are improved by introducing live tooling.

Read MoreGWS Tool Group Fills California/Northern Mexico Positions

GWS Tool Group has hired Bryan Comyns and Walter Lopez as, respectively, business development specialist and application specialist for the California/Northern Mexico region.

Read MoreSumitomo Offers Expansive, Consumer-Friendly Catalog

Sumitomo’s new 21-22 General Catalog includes customer-oriented information on the company’s largest batch of new products since it opened a USA branch in 1979.

Read MoreCeratizit Dragonskin Coating Protects Tools From Heat, Wear

Ceratizit’s Dragonskin coating technology enhances tool durability and heat resistance.

Read More