Vertical Turning Center for Aluminum Wheel Cutting

Sponsored Content – IMTS 2016 Technology eNewsletter

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

Do your current cutting machines allow you to bid on new aluminum wheel jobs? We can see you shaking your head.

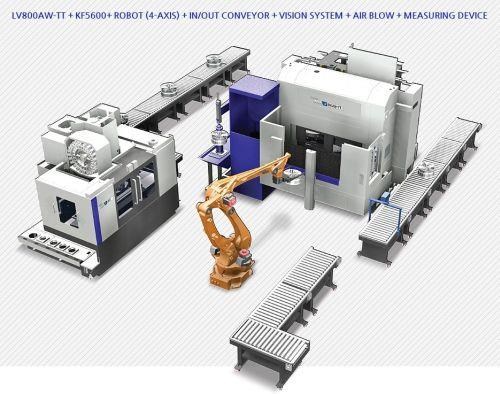

Hyundai Wia’s new high-performance LV800AW-TT vertical turning center is the best-performing machine in the aluminum wheel automation lineup. With a maximum aluminum wheel processing capacity of 21.5 inches, this machine can take on just about any wheel design.

Key features include:

-

Two-turret, high-speed aluminum wheel processing

-

ACC servomotor-based speed control and minimized shock at shut-down

-

Built-in, high-precision spindle for optimal accuracy

-

Automatic chuck changer with high-speed, 180-degree index rotation

-

Rigid, roller-type LM guideway

Designed with automation in mind, combining the LV800AW-TT with Hyundai Wia’s robotics and conveyor system turns your single cutting machine into a complete aluminum wheel manufacturing system.

Learn more by visiting the company’s imts.com showroom.

Related Content

-

SMW Autoblok Workholding, Automation Solutions Optimize Milling, Grinding Operations

IMTS 2024: SMW Autoblok presents the WPS XL for milling, measuring and grinding operations with five-axis and large part workpieces, as well as several products from its electronics and automation line.

-

Keyence Multi-Sensor Measuring System Targets Quality Control in Metrology

IMTS 2024: Keyence introduces the LM-X Series Multisensor measurement system for high-performance measurement, automated inspection processes, accuracy and quality control.

-

Trak Machine Tools Lathes Offer Compact, Heavy Duty Performance

IMTS 2024: The Trak TC2 and the Trak TC820si are compact lathes designed for production applications.

.png;maxWidth=300;quality=90)