Teknics Releases Zerolox Five-Axis Workholding Console

Teknics has released the Zerolox XP 80Z Zero Point workholding automation console, which is designed for improved repeatability and high clamping force.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

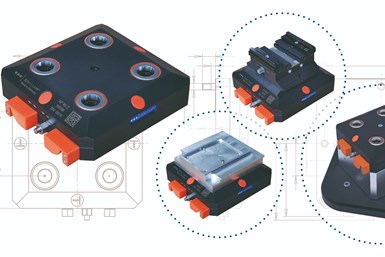

Teknics ZeroClamp USA has introduced its Zerolox XP 80Z Zero Point workholding automation console, which is made in Germany. The Zerolox Console provides a universal interface that enables precision positioning for clamping five-axis self-centering vises, pallets and workpieces on three, four and five-axis CNC machines.

ZeroClamp’s Zero Point center cone technology offers high rigidity and accuracy of 2.5 um (0.0001") repeatability. Thermal growth is always at the center point of the console, according to the company.

The four integrated 90-mm Zero Point clamping units provide high clamping forces of 50,000 N, 11,240 lbs and over 5.5 tons. The console measures 40 mm high by 160 mm2 (1.57" × 6.3 in2) and the 90-degree indexing on each unit allows rotation for a second operation or sides four and five.

The console can be used with ZeroClamp’s five-axis self-centering automation ZeroVise M 80/120 A, up to 203 mm/8 in2 pallets, fixtures, direct part clamping, dovetail fixtures and 52/96 mm mounting pattern on compatible five-axis vises with an adapter plate.

It is pneumatically actuated with 90 psi required to unlock the console, and includes pneumatic porting for automation. No rotary unions or airlines are required, as it operates without a constant air supply. It can be mounted to a five-axis CNC with or without a riser, four and five-axis rotary tables, tombstones, trunnions and all automation systems.

The ZeroClamp manually actuated five-axis self-centering ZeroVise’s M80/120A are available in 80-mm and 120-mm-wide sizes and come with 4 integrated size 90 Zero Point clamping studs. The vises are sealed and self-cleaning with a chip-repelling design to keep cutting chips and coolant from collecting and entering inside.

It is well suited for cobots/robots. Reversing the jaws and changing the two quick-change jaw positions does not increase the vise length, allowing the use of short tooling. Quick-change interchangeable jaw options are available.

Related Content

-

4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

-

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

-

Increasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

.JPG;width=70;height=70;mode=crop)

.png;maxWidth=150)