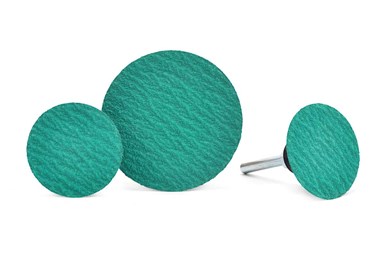

Shur-Kut Grinding Aid Quick-Change Discs Extend Disc Life

Superior Abrasives now offers Zirconia Grinding Aid Quick-Change Discs, which enhance durability by reducing friction and early breakdown of grains.

Superior Abrasives LLC says its Shur-Kut Zirconia Grinding Aid Quick-Change Discs feature long-lasting, durable grains and sharp cutting action for extended stock removal with low heat generation. This cooler cut reduces friction and premature breakdown of grains and backing, lengthening disc life. A hybrid grain exposes a fresh cutting edge during use for aggressive grinding on stainless steel and exotic alloys, as well as ferrous and non-ferrous materials.

The company recommends its Shur-Kut Zirconia Grinding Aid Quick-Change Discs for general purpose grinding and stock removal, deburring or parting line removal on cast parts, spot weld removal and blending, mold and cavity grinding and refurbishing, and grinding and preparing hot castings. These disks are available in type S or R in 1 ½”, 2” and 3” diameters for use with right-angle die grinders. Available grits range from 36 to 120, with optimal speeds of 7,000 to 13,000 rpm and maximum speeds from 20,000 to 30,000 rpm.

In addition to zirconia, Superior Abrasives offers Shur-Kut Quick-Change Discs with ceramic and aluminum oxide grinding aids to suit a wide variety of applications. Regardless of material, the company says the use of grinding aids significantly reduces heat to extend disc life.

With a smaller diameter, quick-change discs enhance performance for intricate parts and enhance control when shaping or blending surface portions, especially on flat surfaces. The moderate flexibility of these disks and their holders allows contouring and access to inner corners. Additionally, the quick-change functionality reduces changeover downtime and eases transitions between grit, material or abrasive type where multi-step processes are required.

Related Content

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

-

10 Things to Know About Creep-Feed Grinding

Because of the high material removal rate creep-feed grinding can deliver in challenging materials, grinding might not be just the last step in the process—it might be the process.

-

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.