NCSimul Improves CNC Quality Assurance and Traceability

Westec 2021: NCSimul 2022.0 includes access to MachiningCloud, which provides cutting tool components that can be exported to CAM or other simulation software.

Share

ECi Software Solutions, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

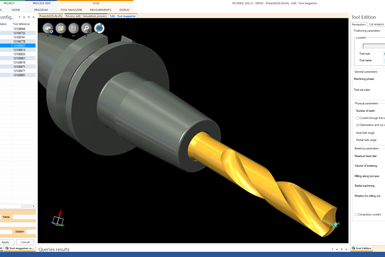

View MoreThe latest release of NCSimul includes direct access to MachiningCloud, an Industry 4.0 solution providing a knowledge base of cutting tool manufacturers. MachiningCloud offers the ability to search for tool components, which can be exported to CAM or other simulation software. The imported data is displayed in the tool library editor, enabling adjustments to tool number, gauge value, reference name and more.

The update also enhances the NCDoc reporting module with functions that make it possible to monitor the checks performed on a program before sending it to the workshop. According to NCSimul, these new features improve quality assurance by adding traceability. All actions, calculations and analyses monitored during the session are displayed in the product information windows and in the documentation via a checklist. The documentation generated by the module is now embedded in the NCSimul project, so it can be viewed by the operator in the workshop from NCSimul Player.

Another update is to the simulation itself; it is now possible to view the coolants activated by the program. All types of coolant can be animated, including exterior multi-nozzles, cabin washing, blowing and more. The definition of the nozzle properties (position, orientation, length of the jet and color) is done in the kinematics editor, while the animation is an option of the simulation parameters.

In addition, the new Esprit interface for milling and turning enables users to send data such as 3D elements, tools, programs and origins to NCSimul. The user can start the simulation without making any changes to the project.

Related Content

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)