In-Port Sequence Valves Enable Faster Deep-Hole Drilling

IMTS22: Vektek’s in-the-port sequence valves enable a single circuit to sequence up to a dozen individually sequenced devices.

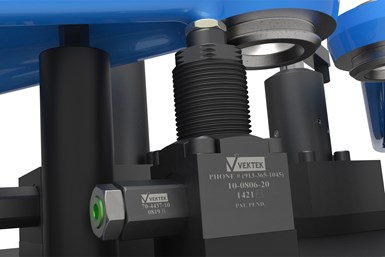

Vektek says it has revolutionized hydraulic circuit sequencing by eliminating the need for complex, multiple circuit deep-hole drilling with its in-the-port sequence valves.

According to the company, users can save time and money reducing their design time and deep hole drilling. Vektek will be at IMTS booth 431922 to demo how its in-the-port sequence valves enable a single circuit to sequence up to a dozen individually sequenced devices. These valves can be installed directly into the device port and can be individually adjusted to sequence or time users’ clamps.

Three pressure ranges are available, as well as adjustability within each range. These sequence valves work with flange-manifold mounted Vektek Port Ready devices and can be added after the design and build process.

Vektek says it provides latest in hydraulic clamping solutions across a wide range of applications. Its manufacturing facility is in Emporia, Kansas.

Related Content

-

6 Trends in Additive Manufacturing Technology

IMTS 2024 features a larger Additive Manufacturing Pavilion than ever before, with veteran suppliers alongside startups and newcomers at the front of the West Building. As you browse these exhibitors, as well as booths found elsewhere at the show, keep an eye out for these trends in AM.

-

Platinum Tooling Knurling, Marking Tools Increase Accuracy

IMTS 2024: Platinum Tooling displays QUICK knurling and marking tools from Hommel & Keller.

-

Solid Diamonds and a Speakeasy: Meeting Q-Mark Metrology

Q-Mark has built its metrology business by providing what customers need, when they want it. This goes for its IMTS booth, too, with free drinks alongside custom technology.