Cambrio Enhances Solid and Surface Modeling for Software

GibbsCAM 2022 introduces a number of usability enhancements, such as automated multi-shape predrilling and extended control for start/end points of profiling toolpaths.

Share

Takumi USA

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

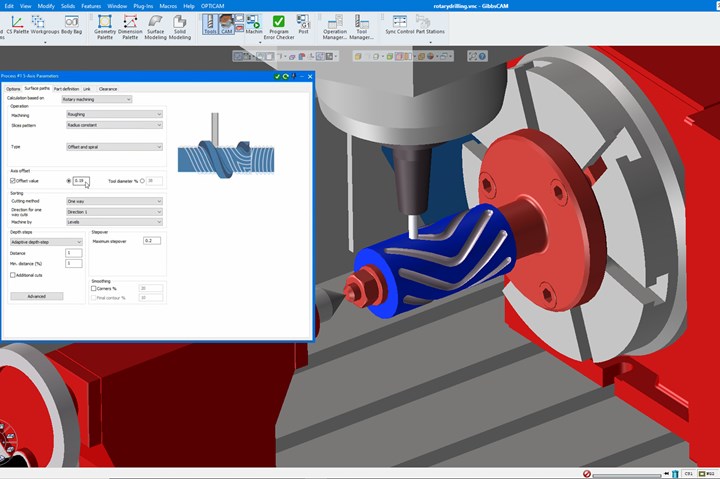

Five-axis enhancements include a new rotary machining strategy to cut parts with cylindrical or conical floors. Photo Credit: Cambrio

Cambrio, a leading CAD/CAM innovator in the production machining industry, has released GibbsCAM 2022, which includes a number of CAD enhancements for solid and surface modeling.

GibbsCAM 2022 features the ability to extrude multiple bodies with taper and to create surfaces as a stitched body directly from closed 2D geometry. Cambrio says users can automatically create trimmed planar surfaces in any orientation at geometry depth instead of the CS plane. Further developments include new alignment capabilities, which enable straight edges of solid bodies to be easily aligned with the working coordinate system in preparation for machining, as well as a new sectional view slicing plane that can be moved in any direction to easily view and select features within the interior of a solid body.

A number of usability enhancements have also been included in GibbsCAM 2022, such as automated multi-shape predrilling and extended control for start/end points of profiling toolpaths. It is now possible to omit radius moves on outside corners of turning operations, which is said to make it easier for lathe operators to adjust critical diameters and reduce output size of G-code files.

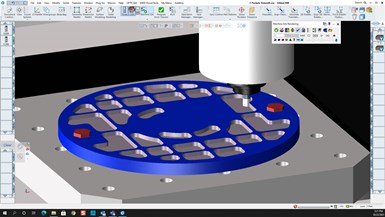

VoluMill enhancements are said to deliver time savings of up to 60% on calculating rest milling operations.

Photo Credit: Cambrio

In addition, Cambrio has improved VoluMill, and it can now reportedly deliver time savings of up to 60% on calculating rest milling operations on complex geometry. Users can control the preferred starting zone for symmetrical cuts to aid chip evacuation and reduce rapid movements for deeper pockets.

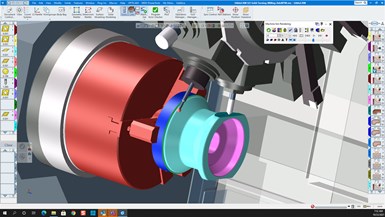

Five-axis enhancements include a new rotary machining strategy to cut parts with cylindrical or conical floors such as feed screws or augers. Advanced control of the tool includes off-centerline roughing and front or back engagement of the tool point with automatic corner offset. New five-axis deburring enhancements include the ability to generate multiple cuts to approximate a chamfer or fillet on an edge beyond traditional edge breaks. It is also possible to use cylindrical or conical tools for chamfering by selecting a specific contact point to keep a straight tool section. Toolpath quality is also improved for five-axis Geodesic operations in areas where multiple surface normal instances control the toolpath. Other five-axis updates include automatic tilting for collision avoidance for arc leads, and the ability to select automatic tilt limits or set a fixed tilt angle relative to a selected surface normal.

Stock generation enhancements on multi-spindle machines can reportedly decrease the simulation time of MTM configurations by up to 25 times.

GibbsCAM 2022 also introduces the ability to hide multipart cutting in all simulation modes to reduce the verification time based on the number of components being machined. The use of 3D material only stock generation on multi-spindle machines can increase the simulation time of MTM configurations by up to 25 times. Additionally, the user is now able to start simulation part way through a multi-flow MTM or Swiss program.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.