Mastercam Integrates G-Code Simulation from CAMWerk

NC2Check detects errors that lead to machine downtime, damage to the workpiece or even expensive collisions on CNC machines before the real machining even begins.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

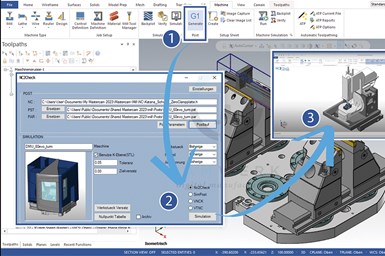

CNC Software LLC, developers of Mastercam, a leading CAD/CAM software, has partnered with CAMWerk on an integrated machine solution called NC2Check.

Mastercam developers worked closely with CAMWerk to build a solution for G-code simulation within Mastercam. The integration gives Mastercam users a solution for avoiding machine damage, downtimes and failures.

N2Check precisely simulates the CNC machine and the entire process of machining. By verifying the NC code through NC2Check, users have an NC code-based, virtual machine simulation of all movements. NC2Check is designed to detect errors that lead to machine downtime, damage to the workpiece or even expensive collisions on CNC machines before the real machining even begins.

“We are excited to partner with CAMWerk on a complete mapping of the entire machine tool and simulation of NC programs based on G code and make it available to over 300,000 users,” Stas Mylek, partnership program manager for CNC Software LLC, says. “The collaborative effort between both companies provides Mastercam users [with a] complete machine simulation for detecting issues such as travel limits or potential workpiece collisions before machining takes place.”

NC2Check is an add-on to Mastercam that installs as a single button on the ribbon-bar interface. The single button enables users to launch NC2Check to provide full simulation and G-code verification from within the Mastercam session.

Bircan Öztürk, director for CAMWerk, says, “With NC2Check, you can see collisions and errors directly on your PC and run on your machines completely virtually. We do not offer G-code simulation in the classic definition, we offer our customers the freedom to create ideas and creatively use ideas elsewhere in the company instead of looking for errors in the NC program, and to run in every single part on the CNC machine. It is a small tool, but its effect in production makes it a real-time miracle for everyone.”

Related Content

-

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

-

Automated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)