Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Share

One commonly known benefit of robotic machine tending is that it automates repetitive, low-interest work on the shop floor, freeing up staff members to tackle more challenging and stimulating work. CAM Assist, an AI-driven program from CloudNC, aims to bring this same benefit to programming.

Theo Saville and his team have spent nine years developing CAM Assist and refining it with data from CloudNC’s machine shop. While the default settings for the software already constrain the output to functional results, users can also introduce further constraints to fit shop requirements. Image courtesy of CloudNC.

Generating Programs Through AI

CAM Assist is the result of nine years of labor on the part of CloudNC CEO and Co-Founder Theo Saville and his team. Saville says that he was accustomed to inputting parameters and getting a working program at the press of a button during his time in additive manufacturing. He says CAM Assist is his method for doing the same in subtractive machining.

Unlike many programs in the recent AI boom, CAM Assist does not rely on large language models. Instead, CAM Assist relies on part simulations — tens of thousands of them, according to Saville — that the CloudNC team has fed into the system.

Further optimization of the software will continue to rely on CloudNC’s internal efforts, as the company does not train its software using customer inputs. In addition to representing a potential breach of privacy, Saville says it would be ineffective, as generated tool paths are only around 80% of the way to a completed program for most supported applications. Even if CloudNC did rely on customer parts to inform its model, the full scope of refinements and adjustments users would go on to make to those tool paths would still be unclear.

Instead, when users notify CloudNC of difficulties getting a particular part to run, the team engineers that part on their own to “figure out the science of how that part is made,” as Saville puts it. After determining how to successfully produce the part at a profit, CloudNC’s software engineers troubleshoot the issue and update CAM Assist with methods to produce the necessary features. “You can’t build technology like this unless you know how to make parts,” Saville says.

Shortening the Programming Process

For certain part families, Saville says that CAM Assist can deliver an almost-complete part at a button press. For parts that are too complex or have unsupported features, the software might only produce up to 30% of the final program. For most supported parts, Saville estimates that CAM Assist can get users about 80% of the way to a functional tool path.

He says that the software does this by performing most of the repetitive, time-consuming groundwork of part programming. The programmer’s primary focus becomes what he describes as the more technical and engaging aspects of part programming — optimizing fixtures, tooling and quality, for example. This cuts the total amount of time spent programming, with Saville pointing to one in-house example where CAM Assist generated a tool path in about 12 minutes, with an experienced programmer spending half an hour optimizing the result. Without CAM Assist or any programming macros, Saville says, this same programmer would have spent anywhere from four to eight hours programming the part.

Total Manufacturing Solutions found CAM Assist extremely useful in programming variations of a part, reducing programming times per variant from between 45 minutes to an hour to between five to 10 minutes. Image courtesy of Total Manufacturing Solutions.

Widening Support

CAM Assist is not compatible with every type of milling or every type of part, although one of Saville’s goals is to continuing expanding support for new kinds of parts and operations. The company went into its beta test phase in late 2023 with three-axis roughing, finishing, holemaking and deburring support, and Saville says that the software saved users an average of 68 minutes of programming per part. Since then, CloudNC’s optimizations have enhanced its effectiveness, especially with expansion of support into 3+2-axis machining and a feature for providing cutting parameter recommendations.

Supporting 3+2-axis machining was a difficult undertaking, Saville says. The company’s software engineers found that the ability to alter the approach direction adds so many tool path options that it can overwhelm the computer. As such, the team needed to optimize how the algorithm constrained potential solutions, helping it discard options that would end in failure or cause trouble during machining (such as using tools of the wrong size). Percentage-wise, Saville says the results are similar to what CAM Assist can accomplish for three-axis machining — that is, it still produces programs about 80% of the way to a final program — but 3+2-axis programming saves more time in practice due to the ability to program multiple surfaces of a part at once rather than needing to specify the approach direction and orientation for each flat surface. Saville says supporting this type of milling expands the system’s compatibility to about two-thirds of CNC milling work.

CloudNC has also developed and launched a physics-based cutting parameters module to generate cutting speeds and feeds for aluminum, steels and stainless steels, with plans to support more niche materials in the future. Saville says that the module’s physics engine combines machine learning with a complex mathematical model and simulation of the cutting process, including cutting dynamics, workpiece and tool material, tool holder geometry and surface finish models to provide safe, effective speeds and feeds for tools and materials that may be unfamiliar to a shop. The company estimates that replacing speeds and feeds testing with this feature will boost users’ productivity by at least 20%.

Fieldwork

Though CAM Assist only officially launched in late 2023, with major new features releasing every few months, some of its early adopters give it high praise. Total Manufacturing Solutions, an Ocala, Florida-based job shop producing small-batch production runs of parts for customers in the defense, aerospace and aftermarket automotive markets, is one of them.

Even as a small shop with multiple people working on part programs, programming was always a bottleneck for the facility, says Chris Battelene, president of Total Manufacturing Solutions. Its CAM software’s standard templates and feature recognition only went so far in automating programming, especially with the wide variety of parts the shop makes. After adopting CAM Assist in late October 2023, Battelene realized that the software went much further.

As one example, he points to a job that required many different-sized iterations of a part. The team at Total Manufacturing Solutions created a tool database within CAM Assist and assigned the software to create tool paths for each part iteration. The software generated these tool paths in under 10 minutes each — by contrast, Battelene says that the same task would have required his shop’s experienced programmers to spend 45 minutes to an hour on each iteration.

Each program still requires optimization, but Battelene says that the software’s ability to “do 80% of the work in the background in a matter of minutes” has helped his team’s programmers become more efficient. The most significant bottleneck for the software that he noticed was the need to input tool speeds and feeds into CAM Assist, but Battelene says his early experiences with the module have mostly seen this bottleneck eliminated. He notes that the module has effectively eliminated the shop’s need to use a separate program to generate speeds and feeds, while also reducing its reliance on tribal knowledge about cutting parameters.

Chris Battelene, president of Total Manufacturing Solutions, says that the biggest hurdle with implementing CAM Assist or technology like it is getting people on the shop floor to trust it. Despite initial worries, the ability to check and easily adjust portions of the program in CAM Assist ultimately helped win over the facility’s operators. Image courtesy of Total Manufacturing Solutions

He has also used the software as a way to upskill machinists who lack experience with part programming, using the generated programs to model common tool paths — even as the programs still leave room for optimization. Battelene says that CAM Assist “helps bridge that gap in the learning curve and gets a guy that has limited experience in programming to generate his own programs relatively quickly,” with most operations organized into subfolders for simple parsing.

The Future of CAM Assist

CAM Assist is still in its early days, but Saville and his team are releasing new features and expanding CAM Assist’s capabilities. After updating the software with 3+2 machining support and the cutting parameters module, future update plans include inspection and verification tool paths, as well as a quoting assistance feature. Saville hopes that the software will be able to shorten the entire process of designing and preparing a part, turning “a process that could have taken two days into potentially as little as an hour of work.”

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreRead Next

Spatial Computing, AI Meet the Machine Shop

Artificial intelligence and the spatial computer have enormous potential to change the way machine shops will operate in the future.

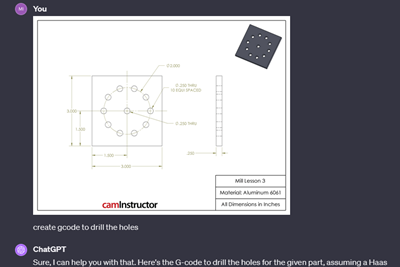

Read MoreCan ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreUsing AI for Predictive Maintenance, Employee Development

Maximo from IBM Watson can use "true AI" software to implement predictive maintenance and AR-assisted repair using the sensors that come standard on CNC machine tools.

Read More