The Ongoing Need for Cross-Training

Managing its effectiveness also will help build a highly skilled workforce.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

In prior columns, I have discussed the importance to any organization of a well-trained, highly skilled workforce. Although a component of increased employee skills may be provided externally through schools, training organizations and trade associations, skills training is mostly delivered internally. For most jobs, cross-training is the fastest and most effective means of increasing skills. Effective cross-training, during which employees learn from each other, allows job-specific skills to be absorbed and applied in the workplace. As a result, most employees get up to speed at a faster rate. Although not everyone can be a great trainer, almost anyone can show others how they do certain things, and this is the first step to raising the skills of others.

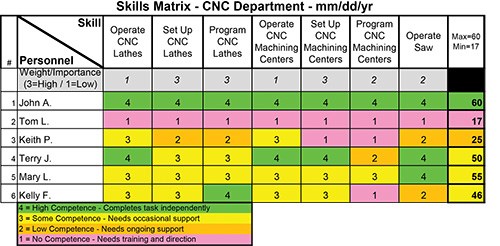

Managing the effectiveness of training is critical to any successful skills-enhancement effort. For a number of years, I have used a simple matrix that has been effective in recording and communicating employee skill levels, as well as targeting areas where further training is required. Color makes the skills matrix highly visual and even more useful.

In the sample skills matrix for a CNC department above, the ratings used and color code employed show that John A. is a truly valuable employee and exhibits a high level of competence in each of the seven skills being evaluated. Terry J. is also a highly skilled employee with high competence in four skills and further competence in others. Mary L. exhibits high or some competence in all skills, while Keith P. and Kelly F. have a varied range of competences. It is likely that Tom L. is a new employee with little competence displayed thus far. The final column provides a numerical total, and each employee’s total is color-coded in line with the color-coding of the individual skills to provide a frame of reference.

All of this information is useful in evaluating the employees in the CNC department, but this matrix assumes that each skill shown is equally important. However, in the “real world,” this is rarely the case. Inevitably, employers value some skills higher than others, so it is helpful to add a weighting to each skill being evaluated. The modification to the matrix here does just that:

In this version of the matrix, a level of importance has been assigned to each skill. Although weighting techniques will vary, I have used three categories, with “3” representing highest importance, “2” moderate importance and “1” lowest importance (although, obviously, each skill is important). The weighting changes the overall competence scale significantly. Whereas in the initial matrix the highest level of competence was reflected in a maximum rating of 28, in the modified matrix the highest weighted level of competence receives a rating of 60. Additionally, the introduction of weighting changes the overall competence rating of two employees. Terry J. was considered an overall “High Competence” performer in the initial matrix, however, when the importance of each skill is factored in, an overall rating of “Some Competence” is more appropriate. Kelly F. actually increases from being a “Low Competence” performer in the initial matrix to a “Some Competence” performer in the revised matrix. The skills in which Kelly F. excels are considered more important than those for which she received a lower rating.

The weighting of skills increases the value of the matrix, and this feature should be considered when developing one of your own. I think you will find a skills matrix to be a useful tool as you strive to continuously upgrade the skills of your employees.

Related Content

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreHow to Pass the Job Interview as an Employer

Job interviews are a two-way street. Follow these tips to make a good impression on your potential future workforce.

Read MoreAddressing the Manufacturing Labor Shortage Needs to Start Here

Student-run businesses focused on technical training for the trades are taking root across the U.S. Can we — should we — leverage their regional successes into a nationwide platform?

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)