Measuring Surface Finish on Valve Seats

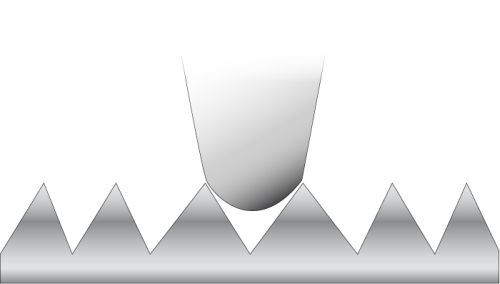

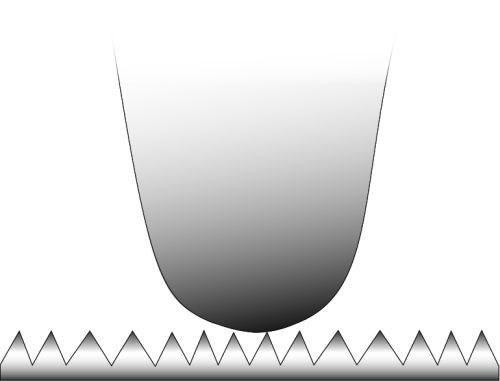

Measuring surface roughness of valve seats on cylinder heads is challenging. The land areas are short, and the roughness values are high. Normally, valve seats require basic roughness parameter analysis by a skidded measuring system. However, because of the short length and high roughness values, some argue that a skidless system is the best way to measure roughness of these surfaces.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

For these reasons—minimizing the effects of mechanical filtering as a result of a long skid length on a longitudinal probe, and having a short skid radius when using a lateral-type skidded probe—skidless measurement probes are often recommended for the evaluation of short-land/high-value applications such as valve seats. Because the datum surface on a skidless system is built into the drive unit rather than being placed at the end of the measurement probe, mechanical filtering of the measurement results does not take place, and measurement results are more accurate.

Read Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)