Modern Machine Shop Talks Die Machining, Moldmaking and Leadtime Leaders

Emily Probst, senior editor of Modern Machine Shop magazine talks with Christina Fuges, executive director of MoldMaking Technology magazine, about 2020 Leadtime Leader Award winner Precise Tooling Solutions and the lessons this moldmaker can teach CNC machine shops.

Please share this video and view more like it when you subscribe to Modern Machine Shop’s YouTube channel.

Transcript:

Emily Probst: Hi, I'm Emily Probst, senior editor with Modern Machine Shop, and I'm here with Christina Fuges, editorial director of MoldMaking Technology magazine. Christina, as I was preparing to talk to you today, I was reflecting on the fact that Modern frequently covers the topic of die/mold machining in our pages, and it seems like this is the type of content that is great for MoldMaking Technology. But, I think that the content you cover is even more targeted than that, right?

Christina Fuges: That's true. Although a mold shop uses similar technologies and processes and faces similar challenges as a production shop or job shop, it’s been an art and craft on its own forever. And with all the technology, it's actually a science nowadays. So, since 1998, we've recognized that this is a valuable niche or segment of manufacturing that is at the heart of the products that we use today. The mold is at the heart of everything. There's a lot more that goes into that than your average workpiece that maybe a production shop is producing. So, most mold builders would say they have different challenges from your average production shop. For instance, a job shop will generally focus on a singular part or process, which will eventually be married to other components in a product. A mold maker has to understand the big picture: They have to understand the part design, the mold cavity design, material selection, machining programming, validating, assembly, testing and sampling. So, even digging a little bit deeper, you get into the geometry of a molded part, and that can be challenging. So what they're actually making, they have to figure out tight dimensional tolerances, flatness specifications, thin walls, complex mold actions within a mold that helps eject parts — all of that requires special part features, special designs, special material options that they have to consider. And on top of all that are cycle times and very aggressive lead times. So I guess in a nutshell, moldmaking is all about highly accurate, one-of-a-kind, custom parts that are very complex and have tight tolerances.

Die Making vs. Moldmaking

Emily Probst: So in the pages of Modern Machine Shop, we often say die/mold together. Can you tell me about the difference? There’s die machining and mold machining. Can you talk about the difference?

Christina Fuges: I guess, to put it simply, I mean both dies and molds are tools for shaping. Dies are used to shape sheet metal or other kinds of metal parts, like car body parts, and molds are used in injection molding, for example, which is the primary process that a mold for MoldMaking Technology primarily talks about with melted resin. And there's also casting for a molten metal, which is die casting. So there's dies, die casting and there's molding. I think molding and die casting are more similar than die. So I guess to put it another way, molds are often used to produce products that need to be hollow in the middle, and dies are used to stamp out solid products, out of steel, for example.

Emily Probst: So, one of the reasons that I have you here today is that Modern Machine Shop is going to have some special coverage coming up in our July issue about die machining. In one of these stories, our editor-in-chief, Pete Zelinski, talked with a panel of people. There was a die maker on that panel and a moldmaker on that panel. Now, the moldmaker on this panel was Precise Tooling Solutions, and you know them very well. They are this year’s Leadtime Leader Award winner. Can you tell me a little bit about the Leadtime Leader awards, what they are and how they’re determined?

Leadtime Leaders

Christina Fuges: Absolutely! It is one of my favorite things to talk about. So first of all, don't let the name fool you, because it's not just about the shops with the shortest delivery times. It’s about what you do with what you have: not the size of the shop you have, or even the specific technology you have, because leadtime is basically the culmination of the entire mold manufacturing process. A quality mold delivered on time is the result of the professionals that are working together from sales, design and manufacturing, to validation, to delivering the mold and to support. So, an MMT Leadtime Leader is a company that performs beyond the status quo using any and all resources available, whether that's your employees, scheduling, machinery, equipment, automation — whatever it is, it's what you do with what you have. That's the most important thing I want people to always walk away with learning or understanding. It's about optimizing what you have to build the best molds and keeping customers coming back because you're meeting their deadlines, and you've giving them a fair price. So again, it's not about being the biggest or the “most-fancy” shop. It's about working smarter with what you have.

So, you asked about judging. The judging board is anonymous, and its makeup varies from year to year. This year, I've identified 12 individuals that are from OEMs, molding facilities — no competing mold shops— and some industry consultants. They are given a score sheet of nine categories, so it's straight up scoring. The Leadtime Leaders fill out a very in-depth questionnaire. And actually, I wish I could share it on the screen right now because it can be intimidating to some people — it's a lot of homework. So, we are taking it seriously. You're not just entering your company or picking a winner. Categories are performance and lead time, projected sales growth, investment in technology, innovation and business strategy, manufacturing efficiency, commitment to workforce training and development, industry involvement and customer service…

Emily Probst: So they have to be all of that? Not just one per category?

Christina Fuges: Exactly. The questionnaire is broken down, so there are the categories that are filling out all this information, and Garner Intelligence really helped us streamline that process. About 10 years ago, it was a very brief, freehand form they were filling out. We got better at making it kind of checkbox and taking any answers. But they also do get scored on the completeness of the presentation, because people can submit videos, photos, anything they want. It's not just the form, so I tend to encourage people to look beyond the form, because you're telling the story of your company, so don't leave it to writing what's on the actual questionnaire.

Emily Probst: Okay, so let’s talk about Precise Tooling Solutions. Give me a bird’s eye view: Why did they win this year?

Christina Fuges: Well, they're very impressive mostly because they're small. They are a 35-person shop, and if you read our June article about them, you will not really think that by all they've accomplished. So Don Dumoulin, who's the owner, came in as a seasoned executive from consumer products and the medical device industry. He's not a mold shop owner, not anything to do with moldmaking. He is at the helm for seven years, and he just comes in and focuses strictly on strategy and leadership on the business. It doesn't happen a lot in mold building and probably not in your sector of the manufacturing world either, right? I remember meeting him at an American Mold Builders Association convention in 2013. He had just purchased the company, and he attended just to network and learn because he had just purchased the shop and knew nothing about it. I remember everybody thinking, “Wow!” And look at them today! He actually took that company through very deliberate steps in the past seven years, and they’re our Leadtime Leader Winner. So, he came in and embraced and empowered the experienced team that he inherited, because he wasn't from moldmaking, and he gave them, and I love this expression that he says, “I give them the runway.” So, he keeps leaning on them to grow. He needs to lean on them because they know what they're good at, and he just lets them run with what they know best. So, it was embracing the team he already had. And every time they grew, their philosophy was making sure they were stabilized until they moved on and were reaching toward that next growth cycle. They're also diversified. A lot of mold shops are only automotive or they're only medical. They are not only a variety of industries, but they do new tooling, they have a business unit focused on repairing maintenance, repair engineering changes, they have a CNC machining business unit, and they purchased the ErgoSmart line. It's a workstation and lift table that they actually build these workstations and they sell them to other people. So that was unique for them.

Besides all the technology — their five axis, their software, their ERP system, cloud-based, and their marketing strategy is pretty cool, which you don't typically see in manufacturing, again as you know Emily. That's not the first thing on their mind, but they use HubSpot, and it actually, I think Modern Machine Shop ended up finding out about Precise because they do regular e-blasts of what's going on in the shop. So their marketing is it's pretty cool, and their customer service.

A Moldmaker’s Lessons for CNC Machine Shops

Emily Probst: Okay, so what I want to do now is take a look at Precise Tooling Solutions some of the lessons they've learned, or some of the aspects of their business that have made them successful, and I want to take these ideas and translate them to something that CNC machine shops can use to improve their businesses. So let's take a look at our first topic here: leading people and creating a company culture. And one of the ways that they have done this is by placing great importance on transparency. And in fact, in the June issue of Moldmaking Technology, which you let me read ahead of time, the owner says that, “Unless people truly understand how they impact the company, they are rudderless.” That's a really powerful quote there. So, going back to leading and being transparent, how does Precise Tooling Solutions do this, and how are they being transparent in their leadership?

Christina Fuges: So, that again goes back I think to Don the owner not having that expertise in mold manufacturing, but he came in with the business mindset. Another thing he said that I liked was, “I believe in people, and when you fully give people the authority and the ability to make the right decisions, they grow. You have to build a team and give them power.” So again, it's back to him, and all that comes down to trust. You can't have transparency without trust. Don believes that every employee — in order to be transparent and build that trust — is they have to know the impact that they're having on the work that they do individually. But they also have to know how their work is impacting the company. He gives them access to metrics such as revenue profitability, all kinds of costs, profit, and he lets them know the projects that make money and projects that lose money. They're always aware of how what they're doing is impacting the company. To me, that's full transparency to the entire organization. He has townhall meetings with everybody, but he also has a core group of four managers that he meets with regularly, and they go over profit and loss statements. They know exactly how much money they're responsible for, how much their department is making or losing, how “off” they are on their goals. That's how he's transparent. I think that's great advice for any shop, because you as an employee want to understand where you stand on what you're working on.

Emily Probst: And we're seeing that a lot with shops making parts to help fight COVID-19. Shops right now are saying that what you're doing matters and where it's going. It’s what motivates you.

Christina Fuges: Yes, motivation, exactly.

Emily Probst: So, so another thing that CNC machine shops can learn from this moldmaker is that it pays to stay up to date with the technology curve. It helps you meet the needs of your customers. So Precise Tooling Solutions has a three-part solution to this. What is the solution?

Christina Fuges: Yes, so he broke it down for me into three phases, and it also goes back to how they're stabilized before they go into the next phase. Phase one is one the company focused on transitioning to a more sustainable business model so that was a lot of focus on ERP (enterprise resource planning) system, and they created a digital environment involving that, and they layered on their ISO certification. That was phase one. So once that was under control, phase two was all about equipment. So that's when they invested a lot of money in their five-axis machining technology in particular, which they have a lot of workhorses in that shop. Then phase three was software focused. It was all about software analysis from design, to programming, to IT. They have a really strong IT strategy that I was very impressed with. And right now, when I was talking to them, they’re changing to an integrated software platform that does everything from design through to product manufacture. So that means different end products. So they were in there investigating different options for that. And all of that. In the end, again, tying to why they're a Leadtime Leader. All of that investment really changed over the years how they make molds. Where it used to be one lead man, or lead woman, managing the whole process. Now within Precise, they’re more like a conductor of an orchestra. They’re not doing all of the work, and that's because of technology.

Emily Probst: So, so my last key takeaway that CNC machine shops can take from this moldmaker is that this company makes it a really big point to not only listen to the customers, but they actively seek out feedback. Christina, how are they seeking this feedback?

Christina Fuges: That again it was another unique area for mold shop. They issue surveys for every project for every customer, and they use HubSpot and Survey Monkey to manage that interaction. They use that to manage all their customer communication. They have a lot of email. They're really way into social media, email, which is great. The survey is about 20 questions, and four of them have been the same questions since Don took over the company in 2013. That's when they started doing the surveys. The responses, especially the same four questions over the years, that's given you a lot of longitudinal data. Looking back to see trends in that data from all those responses has revealed a lot to them, and they've made decisions to change things in their business, according to those survey results.

Emily Probst: In your June article, you mentioned that not only are they putting forth this effort and getting the survey and making decisions based off of this, but they're also being really transparent with it. Again, transparency. How are they doing that?

Christina Fuges: Yes they are. Part of the survey is the fact they provide a year over year comparison of 15 dimensions of customer satisfaction. They take that and share those results with the customer directly, but they also post a summary of it on their website so anybody can see that.

Emily Probst: Christina, I want to thank you for your time here. I think there are some really good lessons from this Leadtime Leader that can be applied to CNC machine shops: 1) Lead with transparency, 2) stay up-to-date on your technology, and 3) see customer feedback, but more than that, use that feedback.

If you want to learn more about the Leadtime Leader Awards visit moldmakingtechnology.com. And if you want to stay up to date on Modern Machine Shop’s upcoming die machining coverage, visit mmsonline.com.

Related Content

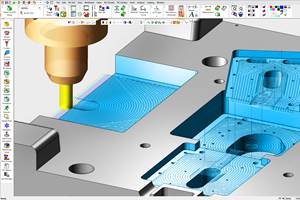

Cimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreLyndex-Nikken Collets Enable Accurate Small-Diameter Cutting

The MMC Mini-Mini collet chuck is well suited for high-speed machining applications where clearance is needed, such as die mold, aerospace and medical parts.

Read MoreGrob Systems Inc. to Host Tech Event With Industry Partners

The 5-Axis Live technology event will highlight new machining strategies for optimizing the production of complex medical, aerospace and mold/die parts.

Read MoreHow to Achieve Unmatched Accuracy in Very Large Workpieces

Dynamic Tool Corp. purchases two bridge-style double-column CNCs to increase the cutting envelope and maintain 5-micron cutting accuracy in the long term.

Read MoreRead Next

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreRego-Fix’s Center for Machining Excellence Promotes Collaboration

The new space includes a showroom, office spaces and an auditorium that will enhance its work with its technical partners.

Read More

.jpg;maxWidth=300;quality=90)