Top 10 Modern Machine Shop Articles of 2022

From offering tips and tricks to spotlighting unique machine shop setups, here are Modern Machine Shop’s top 10 articles of 2022.

As another year comes to a close, it’s time to look back at the top articles from Modern Machine Shop. From a behind-the-scenes tour of an Amish-owned family machine shop to safety considerations for machinists, our editorial team and columnists produced content to pique a variety of interests. Below is a rundown of our top content from the past year.

Modern Machine Shop’s Top 10 Articles of 2022

- When Manual Machining Makes Good Business Sense. Rare expertise, raw passion and ample opportunity keep handwheels turning profits in the era of CNC at Topper Machine.

- Five Safety Considerations for CNC Machinists. Safety in CNC environments is essential for users – and for productivity. Columnist Mike Lynch offers five points worth considering to avoid injury, part failure and downtime.

- Five Things CNC Operators Must Know About Sizing Adjustments. For CNC operators, sizing adjustment is an essential skill. Mike Lynch provides several points to keep in mind when training new CNC users.

- New Machining Technology Works With Old to Restore WWII Submarine. There’s still a place for older machining technology, especially when it’s combined with new. A group of volunteers working with the USS Pampanito knows this well – they’re using a combination of new and old equipment, all donated by the machining community, to restore this historic submarine.

- Inside an Amish-Owned Family Machine Shop. Modern Machine Shop took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

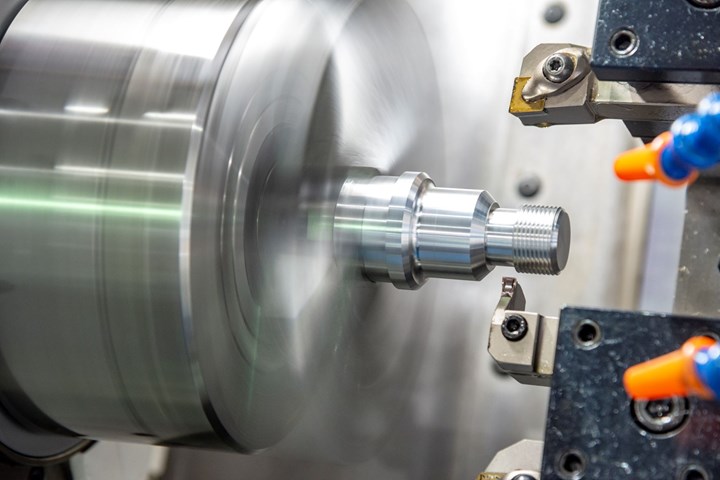

- Turn-Mills 101. Turn-mills are a type of multitasking machine that can shorten cycle times and help facilitate lights-out machining for two common machining types. This article provides an introduction to these machines.

- 5 G-Code Tips for Increasing CNC Efficiency. Optimizing G code is a low-cost way to improve CNC efficiency without sacrificing usability and safety. Mike Lynch gives readers a few tips for doing so.

- All-Around Mill Improves Productivity and Cost for Valve Job.

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

-

How to Drill Holes With a Right-Angle Head. Drilling with a right-angle head in a machining center spindle can be tricky – doubly so if the hole must be peck-drilled. A custom macro and careful attention to positioning help ensure smooth production.

-

The Right (Machine) Tool for the Right Job. This high-production shop uses both mechanical and CNC Swiss machines to make parts. This is partly due to the lower electrical costs and often faster cutting times of the cam-driven machines, while a need for increased precision might make a job fit for a Swiss CNC machine.

If you’re looking for more of Modern Machine Shop’s top content, here are 2021’s top articles.