Rotational Motion Lets Turning Compete With Grinding

Rotational turning provides machined surfaces smooth enough to let turning compete with grinding and polishing.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

“Rotational turning” may sound like a redundancy, because turning already involves rotation. The workpiece spins.

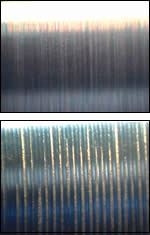

However, rotational turning is a process that adds a brand new rotating element. A special tool pivots to sweep its long cutting edge across the workpiece surface. The result is turning so smooth that it can compete with grinding and polishing.

The German machine tool builder Weisser has patented this process and developed machines for applying it. Machines from this company are represented in the United States by Thielenhaus/Weisser (Novi, Michigan). Company general manager

Tracy Ellis explains that the particular distinction of these machines is that they can turn a surface without the “lead” that results from the feed of a typical turning tool. With rotational turning, in fact, the tool may not feed at all—at least not along the axis of the part.

For OD turning work, the tool is better described as a “blade.” Instead of a single-point turning insert shaped like a triangle, diamond or circle, this rotational turning uses a helix-shaped blade that vaguely resembles the blade of a turbine. The curve of this cutter presents a slanting edge to the spinning workpiece. Pivoting the tool turret in C sweeps this edge across the work, so the cutting action proceeds across the width of the blade from one side of the blade to the other. ID rotational turning uses a different tool geometry and a somewhat different pivoting effect, but the principle is the same. In either case, the rotational turning cut is continuous, avoiding the kind of overlap with its own path that is characteristic of the way a single-point cutter traces a tight winding path around the work.

Thanks to this continuous cutting, if the width of the surface to be machined is smaller than or equal to the width of the blade, then the surface is lead-free—free of these lines of overlap. If the width of the surface to be machined is greater than the width of the blade, then the OD tool can feed along the Z axis to cover the distance while it pivots in C—in which case there is technically a lead. However, both the amplitude and frequency of this surface waviness are much slighter than the lead produced through conventional turning, so the surface is still measurably smooth.

Mr. Ellis says rotational turning is cheaper than grinding and faster than both grinding and hard turning. Compared to grinding, not only is the capital cost less, but the operational cost is less as well. Rotational turning is a dry process that does not require the costs associated with coolant. Meanwhile, rotational turning’s cycle times tend to be twice as fast as those of hard turning, he says.

The blades, which are made of CBN, are supplied by Weisser. Weisser also does the resharpening, though that resharpening occurs far less frequently than the user might expect. Cutting action is not concentrated at a tip the way it is on a conventional turning insert. The cutting action gets spread across the blade, so tool wear occurs much more slowly.

Shafts with critical surface finish requirements represent the ideal parts for this process, Mr. Ellis says. The process can meet the kind of surface finish requirements for these parts that usually call for grinding—though the user may nevertheless need to define more carefully just what kind of finish is needed. Rotational turning produces a turned surface instead of a ground one, and while the surface may be measurably smooth, it will look different. It may even look different in a way that challenges users’ expectations of what a measurably smooth surface can look like. Thus, it may be necessary to specify a greater number of parameters to describe just what surface a user really wants. And that’s OK, Mr. Ellis says—with a lathe, the ability to adjust speed, feed, depth and engagement angle provides a variety of options for realizing specific requirements.

Related Content

CNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=300;quality=90)