Robotic Cell Increases Production Volume Across Wide Catalog

Kawasaki’s robots cut Ossenberg’s pipe processing times by over four minutes and boosted production volume to over 10,000 parts per day.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Takumi USA

Featured Content

View More

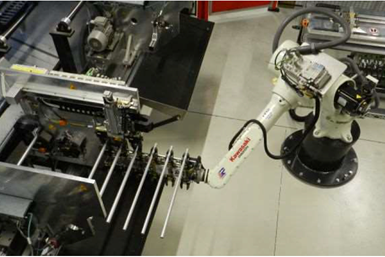

The Kawasaki RS020N is the centerpiece of Ossenberg’s automation cell. This robot positions pipes for its RS050N counterpart to mill, a combination that reduces processing time by almost 85%. Photos courtesy of Ossenberg.

Ossenberg is a long-standing German developer, manufacturer and distributor of crutches, light metal canes and orthopedic aids for global retailers. In response to swift growth and increased product demand, management decided to automate the company’s pipe processing operations. After implementing a robotics cell that could handle Ossenberg’s wide product range, the company’s pipe processing cycle times plummeted almost 85%.

Precise for Every Product

As Ossenberg’s standard walking aids are available in 850 variants, including multiple colors, different materials, adaptable sizes and different load capacities, any potential robotic system would require a high degree of flexibility.

Precision was also a high priority. As part of the efficiency-increasing changes it was implementing alongside automation, Ossenberg planned to mill height-adjustment holes into pipes instead of drilling or punching them. For pipe processing, the company required 0.1-mm positional repeatability and +0.05-mm drilling accuracy. The pipes would also require deburring from the inside and outside at the same time.

Two Robots, One System

While pipe processing cycle times were 5.5 minutes before the company implemented its robotic cell, the new system simultaneously processes six pipes within 50 seconds.

Now pipes are processed by two robots in a 20-foot × 30-foot cell. An RS020N robot moves the welding seam to the correct side for precise alignment, then moves the pipes toward a fixture where an RS050N robot equipped with milling tools mills the height-adjustment holes into the pipes from both sides.

During the final step, the robots can automatically attach the spring-operated push buttons for height adjustment. Depending on the product requirements, they can also recognize bending angles within the outer pipe component.

Success in producing Ossenberg’s parts required adherence to strict repeatability and accuracy standards: a positional repeatability of 0.1 mm and a drilling accuracy of +0.05 mm. By comparison, riveting airplane parts requires an accuracy of 0.3 mm.

Success and Stability

Ossenberg’s production volume and efficiency increased almost instantly. While pipe processing cycle times were 5.5 minutes before the company implemented its robotic cell, the new system simultaneously processes six pipes within 50 seconds. On a macro scale, this increased the plant’s production capacity from over 1,000 walking aids per day to more than 10,000.

“The automation made possible by the Kawasaki robots increased our output exponentially,” says Ossenberg’s managing director, Dietmar Fark. “And there is still room for more. Through specific process improvement, we plan to decrease the time necessary for six pipes to 45 seconds.”

Related Content

-

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

-

Increasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

-

Translating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)