Pulse Power Boosts Electrolytic Machining Accuracy

An advancement of electrolytic, or electrochemical, machining (ECM), precision electrolytic machining is a non-contact process that provides an even more accurate alternative to conventional chip-making processes for jobs involving intricate geometries, difficult-to-machine materials or stringent surface finish requirements.

Share

Since its development in the 1960s, electrolytic, or electrochemical, machining (ECM) has found a niche in jobs involving complex geometries, difficult-to-machine materials or stringent surface finish requirements. However, this non-contact machining process has always been inherently limited by the flow of electrical current, the catalyst for material removal. One recently introduced technology promises to change that, providing a new alternative to conventional chip-making techniques for tough jobs in shops hailing from virtually any sector of the manufacturing industry.

Developed in Germany and introduced to the North American market at IMTS 2010, Precision Electrolytic Machining (PEM) is said to significantly improve accuracy and surface finish by focusing higher-energy current more directly on the workpiece. According to developer PEM Technologies (Ridgefield, New Jersey), PEM can cut intricate shapes in hardened materials to surface finishes as smooth as 1 microinch Ra and tolerances within 0.0002 inch—all in a single operation that doesn’t consume tooling or introduce stress into the workpiece.

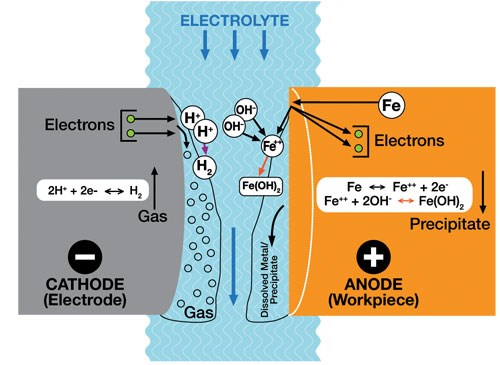

PEM operates according to the same basic principles as traditional ECM, in which an electric current induces chemical reactions that remove material at the atomic level. A negatively charged electrode with the mirror image of the desired geometry (the cathode) advances to within less than one thousandth of an inch of the positively charged workpiece (the anode). A conductive electrolyte solution flows through the gap to complete the circuit. As the current flows, positively charged workpiece atoms break away and attract toward the negatively charged electrode, similar to what occurs during electroplating. In this case, however, the sodium nitrate and water composition of the electrolyte creates a chemical reaction that neutralizes the metal particles, which are carried away without plating onto the tool.

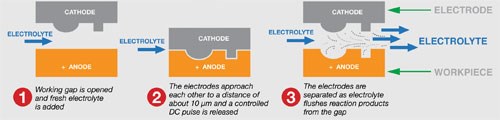

The difference between PEM and conventional ECM is that the former process uses a pulsating current and an oscillating tool. More specifically, conventional ECM maintains a constant gap size and charge, while PEM advances the tool much closer to the part—within approximately 10 microns—and releases a controlled, more powerful electric pulse before retracting. “With a shorter gap, we can draw very high currents because the electrochemical resistance is lower, but only for a short period of time to avoid boiling the electrolyte and degrading the process,” explains Don Risko, vice president of PEM Technologies. “This results in a more accurate representation of the electrode shape on the workpiece and a more polished finish.”

For producing features that would be difficult or impossible via conventional processes, electrolytic machining is equally effective in almost all conductive metals, regardless of hardness or other characteristics, Mr. Risko says. As an area machining process, it can produce large numbers of parts simultaneously with multiple electrodes. Moreover, with no contact between the electrode and the workpiece, it eliminates the risk of mechanical deformities in the part. This enables users to achieve fine, burr-free surface finishes without secondary operations. Unlike electrical discharge machining (EDM), which similarly involves an electrode to remove material, neither the electrode nor the electrolyte solution degrades during the process. Mr. Risko adds that PEM can be as much as five to ten times faster than EDM.

While these advantages can be useful in a wide spectrum of industries, Mr. Risko emphasizes that PEM is a niche process. “It depends on economics and on the particular application in question,” he notes. For example, although it requires a larger up-front investment than conventional machining processes, maintenance, tooling and other costs throughout the lifetime of a PEM machine are typically lower. Mr. Risko urges prospective users to contact his company to set up an application evaluation and obtain an estimate for demonstration prototypes or a PEM machining center. The company also offers contract services for manufacturers who want to take advantage of the process without bringing it in-house.

The company’s PEM machining centers consist of four primary components: the machine itself, which is constructed of granite and stainless steel for rigidity; a PEMPower unit, which provides the modular and dynamic direct current for precision pulse power; the PEMAqua electrolyte system, which offers micro-filtering with variable flow rate, controlled pH, conductivity and temperature control; and the PEMControl system, a PC-based CNC with a touchscreen interface and graphical status display. All of these components are modular, providing a variety of setup options to suit any facility layout.

Read Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)