One New Thing I Learned About Swiss-Types

Cold-drawn stock can be pushed through a Swiss-type’s guide bushing in certain cases.

Share

Autodesk, Inc.

Featured Content

View More

Cold-drawn stock can be pushed through a Swiss-type’s guide bushing in certain cases.

I thought you had to use costly, ground barstock when machining with Swiss-types using their signature supportive guide bushing. Turns out, you might not have to.

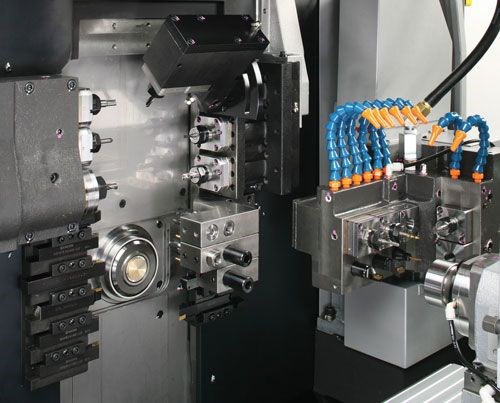

VTD Systems’ Bob Vilagi (president) and Kirk Filker (shop supervisor) say they sometimes run conventional cold-drawn stock through the guide bushing of their two Tsugami Swiss-types. At first, they ran only ground barstock when machining with the guide bushing. However, some of its barstock suppliers hold their typical cold-drawn barstock to accuracies that are sufficiently precise to be pushed through a guide bushing.

Plus, some guide bushing suppliers offer oversized models that can be adjusted to accommodate slightly oversized stock. For example, a bar of half-inch stock may have a diameter tolerance of 0.499 to 0.503. A sticking problem is likely to arise if a bar measuring 0.503-inch is pushed through a standard 0.5-inch guide bushing. It’s possible, though, to use a 0.505-inch guide bushing and adjust it down to accommodate the 0.503-inch bar. This strategy can make a shop more competitive on price because its material costs are lower.

In this story, Bob and Kirk describe how and why they integrated their first Swiss-types and share other such tidbits they’ve picked up along the way.

.png;maxWidth=150)

.png;maxWidth=300;quality=90)