New CNC Equipment, CAM Software Bring Shop to a Fast Start

The startup Dynamic Balance Machine invested in advanced CNC machines and Mastercam software from CNC Software Inc. to more quickly rough out material and reduce cycle times.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View MoreEven when Dynamic Balance Machine of Salt Lake City, Utah, was still a startup company, founding brothers Ben and Danny Lang knew they needed the latest technology to make fast turns on complex, precision-machined components, otherwise they would constantly be playing catch-up. By investing in advanced CNC machines and Mastercam software from CNC Software Inc. (Tolland, Connecticut), the company was able to hit the ground running. Not only did the advanced technology rough out material faster than conventional approaches, it also trimmed down the shop’s total machine cycle time.

Two and a half years ago, the Lang brothers took to the road to cold-call potential customers for their new job shop. Speaking as engineers to other engineers, they discussed their steep investment in CNC equipment and explained that their niche would be machining exotic materials such as titanium, Inconel and tungsten while holding tight tolerances of 0.0002 inch on complex parts ranging in size from 1/8 to 34 inches in diameter, 36 by 36 inches cube, and weighing as much as 1,500 pounds.

In just two days, the brothers lined up enough trial projects that they had to hurry back to the shop to begin work. Today, six of these initial customers still account for a majority of Dynamic Balance Machine’s work in the aerospace, defense, energy and medical industries.

With nearly 20 years of experience as CNC machine operators, programmers and manufacturing process developers, the Lang brothers made a simple observation that became the foundation of their business strategy.

“The way we are making parts today is very different from the way we were operating five years ago. As long as we have been working in this industry, it has been a five-year cycle,” Ben Lang says. “We have every reason to believe that we will be saying the same thing five years from now.”

He says the problem with starting a business the traditional way—buying used manual equipment and hoping to push out enough work to catch up someday—is that they would probably still be five years behind by the time they caught up with today’s technology. Instead, they bought a lathe with live tooling, a horizontal machining center with a 218-station toolchanger loaded with advanced carbide cutting tools, a coordinate measuring machine and a seat of Mastercam CAD/CAM software.

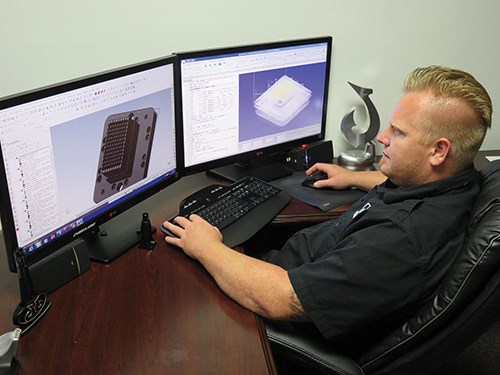

The brothers chose Mastercam because they were familiar with it and aspiring young machinists are learning it at tech schools, and because they believe Mastercam is incorporating features to support the latest machining strategies with each new release of the product. As proficient programmers, the Langs write programs for the next item while their equipment is cutting previously programmed parts at aggressive feeds and speeds.

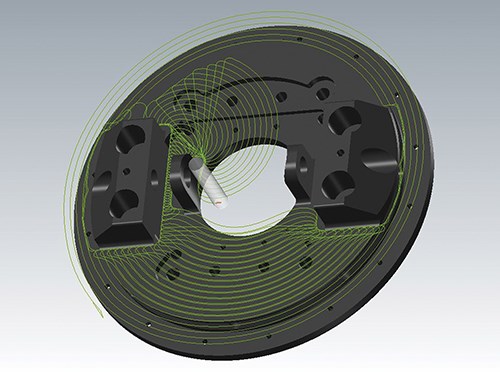

One of Mastercam’s most important contributions to the brothers’ fast-turn business strategy is its Dynamic Motion technology for roughing that is designed to enable the equipment to rough out material three times faster than conventional approaches. Dynamic Motion rules within Mastercam consider the condition of the material ahead of the tool and automatically adjust feeds, speeds and approaches to avoid burying and damaging the tool and the material. This enables the company to move away from a machining strategy that relies on shallow depths of cut and deep stepovers to longer axial cuts and smaller radial cuts.

Dynamic Balance Machine routinely uses tool paths incorporating this technology on parts made of aluminum, stainless and even titanium. Machining parameters are set in accordance to tool vendors’ chip-load recommendations for the material and the particular tool. For example, Mr. Lang says he used to machine aluminum parts with complex geometries at 80 ipm with conventional tool paths, but he now uses Dynamic Motion technology to machine the parts at 250 to 400 ipm. He can also rough titanium and stainless two to three times faster with less tool wear, he says.

He says he routinely uses Dynamic Motion tool paths—particularly Opticore—when roughing parts.

“About 90 percent of the parts we make have a dynamic component to them. The time we save in roughing reduces our total machine cycles by 20 to 30 percent,” he says.

Not only does the program decrease machine cycles, but it also can decrease programming time. Mr. Lang says the Opticore tool paths reduce complex roughing routines that used to require 10 operations to just one. This saves about 30 minutes of programming time per part, or a man-year of recovered time for the shop.

Dynamic Balance Machine uses other strategies to trim manufacturing cycles and get parts to its customers faster. One such strategy is to use more—not less—material per workpiece. With more material, the brothers can design better workholding solutions and take greater advantage of high machining efficiency with Dynamic Motion technology. By using more material, they can get a firmer grip on the part and make more areas accessible to the tool. The time lost in removing extra material is made up by the increased material-removal rate.

Another way the shop reduces its cycle time is by using its HMC with two pallets. The brothers can program and set up a part while another is being manufactured. Change-overs take seconds versus the 15 minutes or more required on a conventional VMC. The company’s workload is balanced 60/40 between production and prototyping. The production programs’ optional stops enable the Langs to swing in a prototype piece and machine it without skipping a beat. This approach ensures an optimized machining strategy for the production equipment if the job moves into production.

The company also uses its advanced carbide cutting tools aggressively to reduce cycle time. According to Mr. Lang, if a customer has an immediate need for a quick turnaround, the shop typically pushes its cutters to the max to get the job done in two days rather than four. This might cost the shop eight additional cutters, but he says the quick turnaround is worth it.

He also says that cutting tools are currently at the forefront of advancing manufacturing technology, so the shop has invested many days building libraries that are preprogrammed and coordinated with the machine. The parameters for each tool are based on years of experience. The Mastercam tool libraries enable the shop to keep its experience-based knowledge at its fingertips.

“That’s where the real secrets are,” he says.

In the past two years, the shop was able to move 1,500 projects through its HMC, which is about what the brothers produced in five years at their previous jobs using more conventional approaches. The shop is on track for 30 percent growth in 2015, and an identical CNC was installed in May.

Related Content

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreGenerating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)