Moving CAM/CAD to the Shop Floor

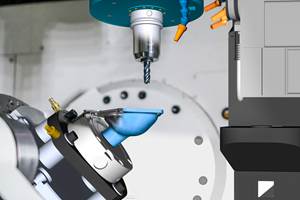

Creating a tool path is no longer the exclusive province of the CAD/CAM department. Shops are putting better CAM tools in the hands of their skilled toolmakers so they can assume responsibility for their own part programs.

Most mold and die makers would agree that shopfloor programming has its role, but also that it is quite limited. While conventional wisdom has it that simple features are sometimes just as easily programmed on the fly--and often must be because it's so hard to get every detail just right on the front end complex cavities and cores are a different matter. It easily can take hundreds of surfaces to define a single form, and it can take days to get the tool path right. The postprocessing alone may take half of a shift. Who wants to try all that in the environment of the shop floor?

But an increasing number of shop managers are saying they do, or at least some of it. For the most part, these shops are still doing the surfacing within the confines of their CAD/CAM departments, but also putting better CAM tools in the hands of their skilled toolmakers so they can assume responsibility for their own part programs. It only makes sense, these shops argue, that those who know best how to cut metal should have control over the tool path. But even more significant--with the growing speed and ease of use of new CAM technology--these shops are cutting huge chunks of time out of their total mold- or die-building cycle.

Industrial Molds (Rockford, Illinois) is a 75-person shop that has undergone this very significant paradigm shift. They too are enjoying the cost benefits of substantially reduced programming time, as well as other time- and quality-related enhancements to the shop's performance. But their formula is not so simple as just dropping a couple of seats of CAM in the shop. Rather, it involves a complete rationalization of how they electronically create and manage all part, mold design and NC data. Here's how this highly accomplished shop puts it all together.

Limitations

This is not to say that shopfloor programming is by any means a new concept to Industrial Molds. According to CAD/CAM manager Bob Morton, they've been doing it to some degree for 15 years. Some of the shop's toolmakers are highly skilled CAD/CAM users, with experience on a number of systems ranging from relatively simple 21/2-axis to high end 3D surfacing systems. So this was a most fertile environment in which to introduce an expanded programming role.

For complex programming of cores and cavities, however, the shop had historically relied on their CAD/CAM department, and that was quickly growing into the company's most seriously limiting bottleneck. "We were spending eight hours preparing programs for every hour we were machining," says Mr. Morton. "We had four guys doing nothing but modeling and programming, and they couldn't keep up with the workload." Even with six seats of a high end CAD/CAM system, they couldn't produce half the output necessary to keep the shop running. Moreover, because they literally were codifying the entire machining process in their part programs, the methodology required extensive job documentation--on setups, tooling and so on--which was in itself a major undertaking.

Then there were other drawbacks. The programmers were not necessarily as expert in the best machining practice as the people operating the machines on a daily basis, and the knowledge gleaned through experience on the shop floor didn't systematically get applied to new programs. Also, it was extremely difficult for someone sitting in an office to anticipate every aspect of a long and complex job. Programs frequently required corrections, and that cost valuable time and sometimes mold rework as well.

Availability of cutting tools was another issue. If a program was generated for a specific tool that was not in stock, the NC program would have to be returned to the CAD/CAM department and rerun with the tools they did have. Such a simple mistake could easily add another day to the mold production cycle and unexpectedly idle one of the shop's machining centers all the while.

So about two years ago, Industrial began the process of shifting responsibility for all tool path generation out of CAD/CAM and into the production department. Along with that move came an additional emphasis on training in the use of the shop's already considerable array of CAM tools--classes that were mostly conducted after hours on a voluntary basis. But it wasn't just a shop-floor issue. Critical to the success of it all was the retooling of Industrial's general methodology of defining part geometry, creating mold designs, and working jobs through the shop.

From The Start

The lynch pin of the entire system, says Mr. Morton, is to get the intended part geometry completely defined in an unambiguous form from the very start. That means creating a solid model, which is done in Parametric Technology's ProEngineer CAD system. It's a preparatory step that perhaps costs a bit more time initially, but pays large dividends in downstream applications.

About half of Industrial's customers already use ProE', and in those cases the models are simply imported. If other IGES surfaces or solids files are supplied, they will typically be re-modeled. On some they may pick up basic wireframe geometry for reference, but then fill out the solid themselves. And in other cases, they may reconstruct the entire model from scratch. The model will include not only the volumes where plastic will flow, but also any required inserts, which is a particular specialty of the shop that is, premanufactured components, such as electrical contacts, that will be inserted into the mold prior to plastic injection in order to be integrally bonded with the final molded part.

While all this CAD work may seem a bit premature, Mr. Morton says that creation of this "neat and tidy file" with an easy-to-use CAD system generally takes less time than trying to patch up most supplied IGES files. But more important, the fully--and consistently--defined solid model helps the job flow much more smoothly through the subsequent tasks of mold design and tool path generation, both of which will be conducted on different, and maybe multiple, CAD/CAM systems.

Once that master file is done, it is sent to the design department where the mold is conceptualized and detailed mostly in AutoCAD, but sometimes also in Cadkey or in ProEngineer. Given the complexity of Industrial's work, this is no simple task. Multiple cavities, inserts and slides are extremely common. Moreover, they must remain flexible to accommodate eleventh-hour customer engineering revisions--all of which are represented in the master model to avoid any subsequent ambiguities or miscommunications.

Once the design is finalized, it is released to the shop. Now it's time to generate the tool path code.

Point And Shoot Programming

Before, where CAD/CAM specialists might have taken 20 hours to do the surfacing and programming on a job, today they spend six hours making a neat and tidy solid model, and then all the programming is done in the shop, on the fly. Yes, there will likely be another increment of programming time in the shop, but that will generally happen quickly and often concurrent with other activities.

How? For one thing, they've taken a different approach to CAM, eschewing high end solutions for something that is much easier to use. While they may sacrifice some degree of control over their ability to manipulate geometry (which is still necessary in some cases) and to some extent tool path too, the gains in reduced programming time are so overwhelming that they'll gladly make the trade.

Around April of 1995, the shop began using the PowerMill CAM system from Delcam, an English company better known for their Duct5 software, itself a high end system designed for die and mold manufacturing. PowerMill is representative of an interesting new breed of NC programming software, aimed at complex sculptured-surface machining, but stripped of the more operationally demanding and time-intensive surface modeling functionality. It's what Mr. Morton refers to as "point-and-shoot programming," so the toolmaker can worry just about how he chooses to cut the various portions of a mold, and then create tool path quickly.

How easy is it? In this case, the system has a Windows-like interface, with most functionality accessed via pull-down menus with default values and settings underneath. A series of buttons runs across the top of the screen, and by working from left to right through them, the toolmaker is led through the programming process.

First, the portion of the part model that represents the core or cavity form is imported as a single entity, and then the simple rectangular volume that represents the block of metal is constructed around it. Thereafter the system models, not the workpiece model, but the material to be removed, with offsets to the part model applied if desired. This volume is represented with a "tessellated" model, meaning the 3D solid boundary is defined in the form of adjoining triangular patches. Tool path is created by taking 2D slices through the material model in various user-definable ways. Automatic functions can be used say, to clear a pocket--or pick and step-down increments can be specified. Boundaries can be set on any given cut, so that different cutting strategies can be applied to different form features.

Roughing routines can be turned loose on the whole form, including constant Z-height roughing with flat-bottom cutters, without worry of gouging. Because the system models the material, it "knows" what stock has been removed and what hasn't and can automatically generate tool path to remove only the remaining stock when smaller tools are used. It can also intelligently adjust stock clearance planes as each level of material is removed, significantly reducing air-cutting time in lengthy roughing operations.

Given the simpler approach to surface representation and cutter path generation, program segments can be calculated and processed at much quicker rates than most experienced CAM users would expect, allowing the programmer more leeway in trying out different cutting strategies. Also, once a routine is formulated, the system stores all intermediate calculations. So, any edits or changes to the original cutting strategies are processed quickly.

CNC machining department manager Mike Gibson says the approach is so expeditious that they are able to keep up with the programming requirements just with existing shop personnel. That's freed the four people who previously spent all their time surfacing and programming to concentrate on other productive functions.

The Bigger Picture

According to Mr Morton, putting such tools in the shop brings a higher level of self-sufficiency that allows them to marshal their technical and human resources more effectively. "Where we used to have four programmers, now we have 50," he says, meaning that virtually anyone in the shop is now capable of generating tool path code, a factor that quite literally wiped out the shop's programming backlog in a surprisingly small amount of time.

But it's more than just that. "They know what tools they have and they know how to cut," he continues, "and they are always trying new tools to see what does the best job." So it's extremely difficult for people who spend most of their time in an office to know even what tools are available, let alone which cutters and which cutting approach does the best job. Transfer responsibility for the cutter path to the shop and chances are better that the program gets done properly the first time.

The machining cycle the complete machining cycle is actually shorter, they find, because tool-makers are getting everything they need up front, which, interestingly, is not all that much--a hard-copy computer rendering of the part and a 3D file. Even with NC programming added to the shop's responsibilities--indeed, precisely because of it--they are able to push jobs through the shop quicker because all requisite tools are at hand.

Greater efficiency means greater profits, a benefit that is shared equally with the company's employees. But the overall benefit of reducing the time required to build complex tools also contributes in a huge way to this shop's competitiveness. "Customers are asking for a lot more in a shorter time frame," says Mr. Morton. That means Industrial must continually find ways to compress the general build cycle of a mold while accommodating engineering changes at multiple points in the process, and sometimes right until the end. This requires deft handling of their job data. Having a single, unambiguous model from which all applications work goes a long way to managing the flow of information.

Industrial's ability to manage this entire process is what allows the shop to react quickly to changing customer needs. It's only through this broad mastery that individual disciplines--be they in the office or the shop--can achieve their full potential.

Related Content

Automating Part Programming Cuts the Time to Engaging Work

CAM Assist cuts repetition from part programming — early users say it could be a useful tool for training new programmers.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreContinuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read MoreImprove Machining Efficiency Through Digital Twin Simulation

Full simulation of a machining cycle using digital twins can not only identify crashes before they happen, but provide insights that enable the user to reduce cycle times.

Read MoreRead Next

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)