When Can Force Harm Gage Performance?

In some situations, the influence of force on gaging devices can make it an enemy to accurate measurement.

Share

There may be a place for “The Force” in the universe, but I can think of three areas in gaging in which force can be detrimental to the performance of the gage or the measurement results.

Dial indicator/probe mounting. A dial indicator is generally mounted by the stem or by a lug on the back. In the United States, where American Gage Design (AGD) standards are the norm, indicators are usually mounted by the back lug. Thus, their mounting position is determined by the lug. Lug mounting can take many different forms, including centered and off-centered, post back with a handle, screw back, adjustable bracket back, rack back with a dovetail bracket, and magnetic back that directly attaches to a machine.

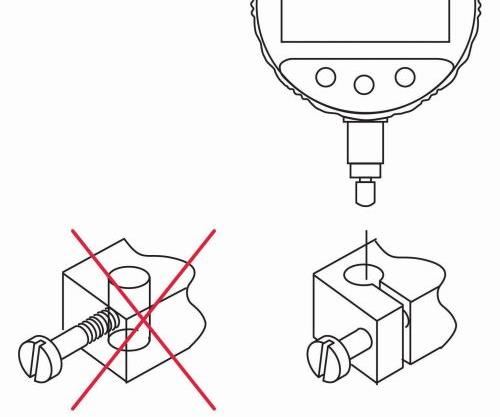

Holding an indicator by the stem, on the other hand, allows the axis of the dial indicator to be easily adjusted square to the measured surface. This style of mounting also makes it easier to adjust the holding position as needed. A disadvantage of this method, however, is that the stem is a crucial part of the indicator. This is where force can be a gage’s enemy. There is minimal clearance between the stem and the spindle, which must move through the stem with as little friction and play as possible. The packaging or instructions supplied with most indicators includes a warning about mounting the indicator this way when the clamping mechanism consists of a setscrew. This is a real problem with most indicators, because the setscrew concentrates its force locally, and if the force is on or close to the slide bearing between the stem and the plunger, it’s very easy to distort the bearing and lock up the indicator. Even a setscrew with a split bushing can pose the same problem. If there is enough room, you can slide the bearing area of the stem past the setscrew and clamp in an area where there is more internal clearance, but more often than not there will still be distortion caused by the force. The best way to hold an indicator mounted by the stem is a split-collet-type clamp that distributes the force evenly and prevents locking up of the indicator.

Compressible materials. Machinists who work strictly in metalworking shops do not have many occasions to gage the thickness of soft materials, but there are many situations in which compressible materials like textiles, plastic films, paper, composites and others need to be gaged. Even those who work with very thin walled metals soon realize that force can have a big influence on measurement.

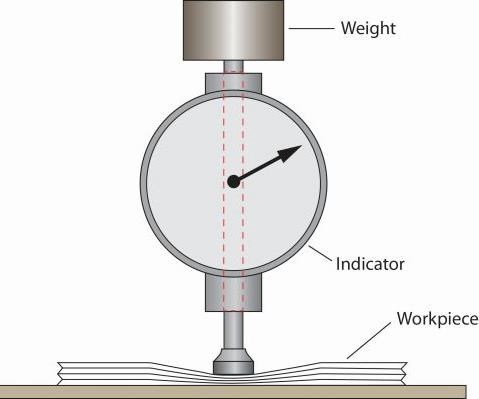

Differences in gaging pressure translate readily into differences in the degree to which the sensitive contact compresses or penetrates the material being gaged. It is, therefore, essential to use a standardized method when measuring the thickness of compressible materials. Every industry and every kind of material has its own standards, most of which have been established by the American Society for Testing Materials or by Underwriters Laboratories. These standards specify the size of the reference table and the measuring contact (or foot), the dial gradations and the amount of force to be used. (Gaging force is controlled by a weight—often referred to as a “dead load”—rather than with the springs found in most dial indicators, to ensure consistency of compression). Such standards make purchasing decisions quite straightforward. Often, you need only specify which ASTM standard you wish to meet.

Assuming you have the right gage made to the right specifications for the material, making accurate measurements of compressible materials is not difficult. Simply choose and maintain the gaging pressure and make sure the right contact diameter is facing the proper lower anvil. This assures repeatable measurements and good correlation to similar setups.

Flexing gages. Most fixtures are made of several component parts and are, in essence, a variation of the well-known C frame. All materials, regardless of their hardness, have some degree of elasticity. That also applies to the frames used to fixture parts for gaging. Small as it may be, this elasticity is a real and vital consideration in a precision gaging setup. Even the slightest force will cause some deflection of the frame; if the deflection is great enough, it will throw off the calibrated accuracy of the gage.

This became obvious with the introduction of digital indicators with data-send buttons. These digital indicators usually had a higher resolution, and users suddenly began to notice that their gages were deflecting and readings were changing whenever the “force” of pressing the Send Data button was applied. Suddenly, readings were not as stable as they had once appeared to be. The simplest way to reduce this variance in readings is to increase the stiffness of the gage frame to the point where the force causing the deflection is no longer great enough to affect the reading. This may mean larger-diameter posts and arms, along with shorter versions.

With a little knowledge, you can defend your measurments against bad forces and secure a victory for good gaging results.

Related Content

10 Things to Know About Creep-Feed Grinding

Because of the high material removal rate creep-feed grinding can deliver in challenging materials, grinding might not be just the last step in the process—it might be the process.

Read MoreSpeeding Up Splines

Moving small- to medium-batch production from outsourced, dedicated hobbing operations to in-house, CNC multitasking machines helps job shops achieve quick turnarounds and flexibility in supplying splines for the heavy-vehicle industry. Inserted disc cutters make this transition possible.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreRead Next

Inside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreIMTS 2024: Trends & Takeaways From the Modern Machine Shop Editorial Team

The Modern Machine Shop editorial team highlights their takeaways from IMTS 2024 in a video recap.

Read More