How Job Shops Can Generate Accurate Estimates in Minutes

Sponsored ContentNew geometry-driven quoting technology lets job shops generate estimates in as little as 15 minutes. It enables them to respond faster to RFQs, drastically reduces time wasted on jobs they don’t get, and lets them focus on more profitable work.

Share

Everything moves faster these days and that includes the level of service that buyers demand from their parts suppliers. It’s not just the lead times that are shorter; buyers increasingly expect estimates almost on demand. And sometimes it’s the shop that responds first that gets the job.

But it’s not so easy for a job shop. Generating a reliable estimate can take hours, even from your most knowledgeable people. Worse, if you’re like most shops, you only land a third of the jobs you quote. All that time is wasted with people who should be out engineering better processes rather than stuck in the office doing low-return paperwork.

There is a better way. The secret to more efficient quoting and landing more profitable business is to spend less time on costing and to give much more consideration to pricing. Paperless Parts CEO, Jason Ray thinks about this a lot. “Job shops spend too long engineering estimates for work they never win,” he says. Ray addresses this problem with the Paperless Parts Quoting Platform, a web-based application that enables shops to generate accurate quotes in an astonishingly short period of time, and also facilitates manufacturing team collaboration in order to make faster, more informed process decisions. The Paperless Parts quoting platform supercharges job shops’ existing systems by streamlining the sales and quoting process. Here’s how they do it.

Paperless Parts CEO Jason Ray explains how the quoting platform is designed to match the way job shops do business.

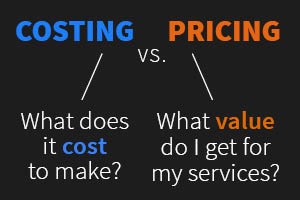

Pricing Vs. Costing

All shops understand costing. It’s examining every feature of a part, figuring out how to make it, adding up the time and materials and applying a markup to determine the value of a part. Pricing is very different. It’s the art of knowing your value from the customer's point of view, and that’s often not just about getting the lowest number. Maybe lead time or guaranteed delivery is critical. Maybe they’d like input on manufacturability of the part to reduce cost. Since these and other factors can vary by buyer and job, it pays to be both attentive and flexible in pricing your quotes.

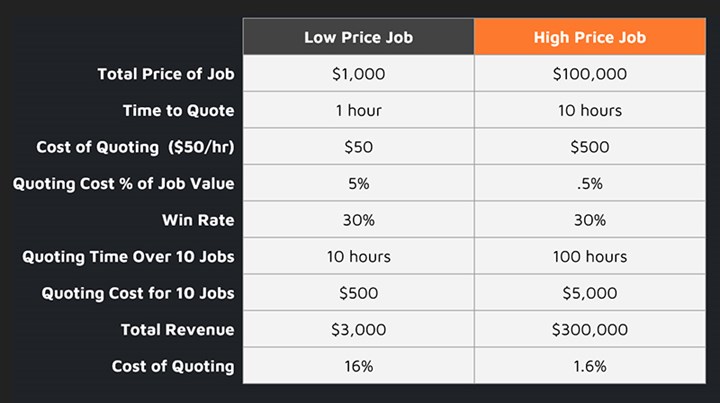

As the graphic below shows, over the course of a week an average shop spends as much as $1,750 worth of time on quotes it doesn’t win, and many “wins” turn out to be jobs that make little or no profit. How do you turn that around? That is, how can you generate estimates more quickly, and better focus on the most profitable work? This is where Paperless Parts comes in. Through geometry-driven quoting technology it automates much of the complex process of estimating and prioritizes quantifying the value of a job shop’s total value proposition. The platform can generate even complicated quotes in as little as 15 minutes, which leaves a great deal more time to consider how the job should be priced in the current customer circumstance.

What’s the real cost of quoting? As much as shops might prefer just running big jobs, the reality of serving customers often dictates a mix of many smaller runs.

As the scenarios above suggest, the smaller the job, the higher the cost of quoting as a percent of revenue. If you take ten $1000 quotes at a modest quoting cost of $50 per hour, and a win rate of 30%, you’ve spent a whopping 16 percent of the revenue of the three jobs you landed just on quoting.

Geometry-Driven Quoting

Many shops store their completed estimates in cabinet drawers, ERP systems, or shared drives. These archives are difficult to search, and impossible to search quickly, which often renders them useless in preparing new estimates. With Paperless Parts previous estimates are stored in a database that is searchable by individual part features.

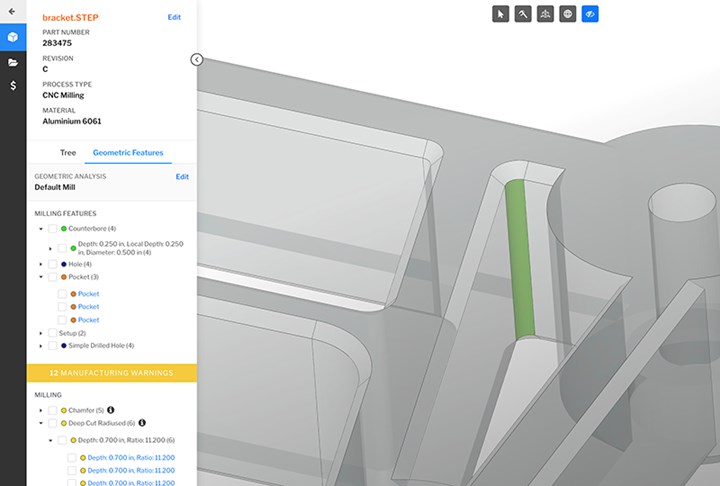

Paperless Parts automatically identifies the features of a part based on the specific manufacturing process required to make them. See full size image.

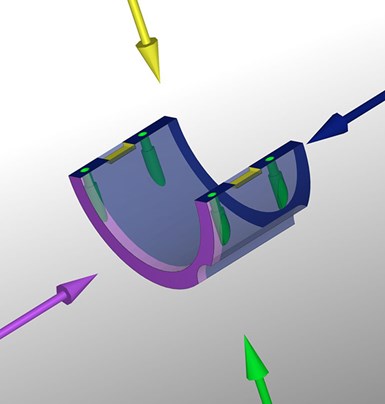

The software also identifies the tool vectors that will be required to machine a part, which is critical to calculating both operations and required setups.

With this methodology, the geometry engine analyzes all the features of a part and compiles all the associated operations required to produce it, all in a highly automated process. Identifying identical (or sufficiently similar) parts from past jobs this way avoids costly and continual duplication of effort, optimizing the time spent by knowledgeable workers.

The geometry engine can even identify potential manufacturability issues like tight corners, deep holes or areas that require special tooling. These design-for-manufacturability thresholds can be customized to any shop’s specific capabilities.

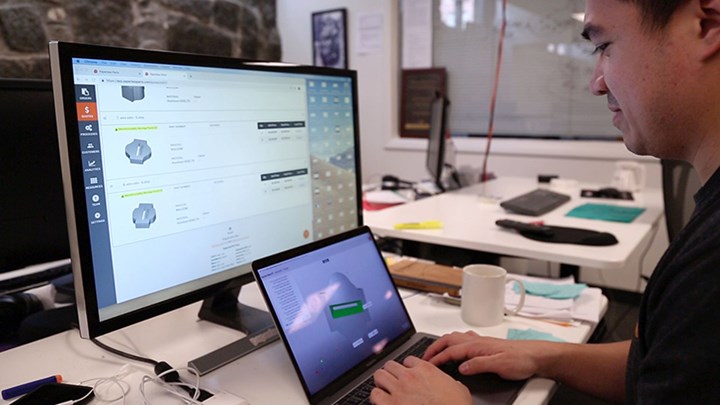

This video demonstrates the user experience of preparing a quote with Paperless Parts. Go here to request a live demo.

Secure Communication and Collaboration

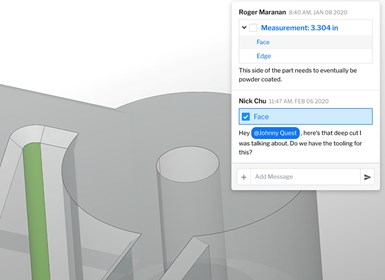

The Paperless Parts platform enables real time collaboration in a completely digital environment.See full size image.

Paperless Parts also serves to securely streamline communication throughout the quoting process with customers, your internal team and vendors in an ITAR compliant system. Customers upload files online through a Smart RFQ Form, and your estimating team then sees the RFQs in a quote management dashboard.

Online file viewing and shop configurable manufacturability analysis means your team can quickly assess the fit of a potential job. If there are questions, anyone involved in the process can open a simple, secure chat to pose questions to all involved and provide traceable feedback to customers. Getting the right answers quickly keeps the process moving forward. Gone are the sporadic disruptive interruptions to engineers during production or that walk across the shop floor to have them review files and provide analog feedback that gets written on the side of a drawing.

Centralized Repository

Paperless Parts tracks the status of all RFQs and estimates in the system, which helps provide better customer service. That eliminates lost RFQs and angry customers who have been waiting days or weeks for you to respond.

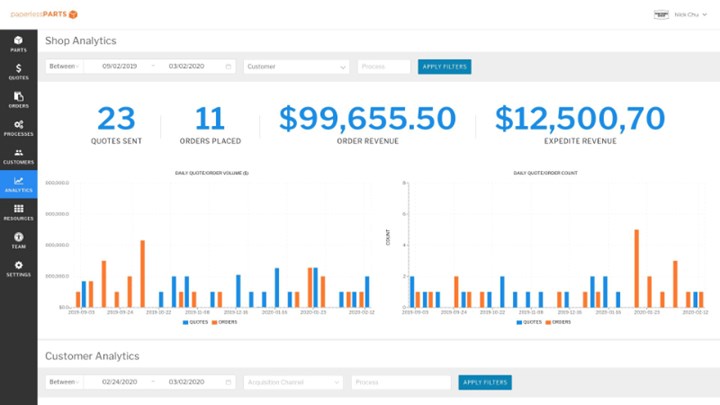

The Paperless Parts Platform provides dashboards where all quoting activity can be viewed in one place. See full-size image.

By being able to see all your RFQs at once, you can be strategic about which jobs you should quote first or at all. You can see your actual win rate overall and by customer. On outstanding quotes, you can see what has been viewed, accepted, or rejected. Combined, these insights help you run your quoting process more efficiently.

Online Customer Interface

Meeting customer expectations more often leads to more opportunity. With the Smart RFQ Form and digital quotes, your customers can now request a quote, review your response, accept that quote, even pay online. In addition to the significant reduction in staff time, this makes it easy for shop owners to track all RFQs at any time, from anywhere, and deliver a secure, professional, modern experience to every customer.

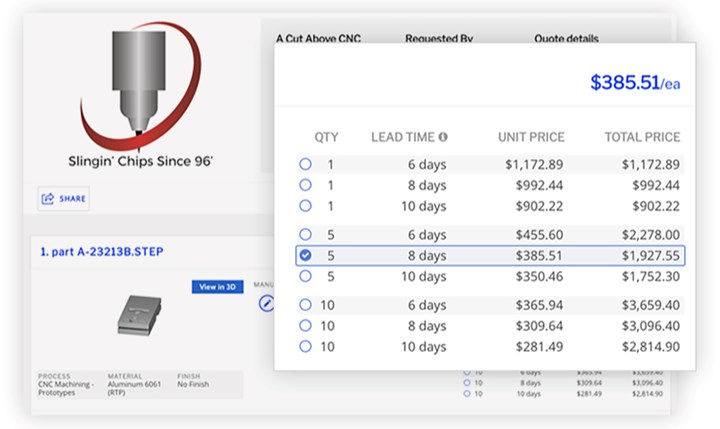

The system can display custom expedite options to the customer that provide options on lead time vs. price. See full size image.

Paperless Parts has modernized the quoting process. It provides the structure to improve your shop's ability to estimate faster with more confidence. It improves the quality and quantity of your quote response and enables your best people to spend more time improving production efficiency and less time estimating.

For more on Paperless Parts, please visit www.paperlessparts.com or go here to request a demo.