How Do You Sell Your Value-Add?

A shop shares lessons learned about alluring and securing profitable, long-term CNC machining contracts.

Contour Precision Milling & Machine moved into a brand new facility in 2006. Two years later, that move almost seemed ill-considered. “We lost about 60 percent of our business overnight,” recalls Michelle Reichlin, CEO, about the economic downturn of 2008.

Thanks largely to a new approach to shop-floor scheduling, the company is reportedly twice as productive and twice as profitable as it was before the move with less than half the employees (21 versus the 2007 peak of 48). Its average on-time delivery rating is 96 percent. CNC machining equipment on the 20,000-square-foot shop floor in North Ridgeville, Ohio, includes pallet-fed horizontal machining centers and five-axis vertical machining centers. Six new pieces of equipment have been purchased in the past 18 months alone, but debt is controlled, and the company is not highly leveraged, Ms. Reichlin says. She and the rest of the company’s leadership believe themselves better prepared than ever for whatever the future brings.

However, Ms. Reichlin also insists that there’s more to thank for success than shopfloor improvements. The company also had to refine its approach to attracting and managing relationships with customers. Here are a few lessons it learned along the way:

It Is OK to Say “No”

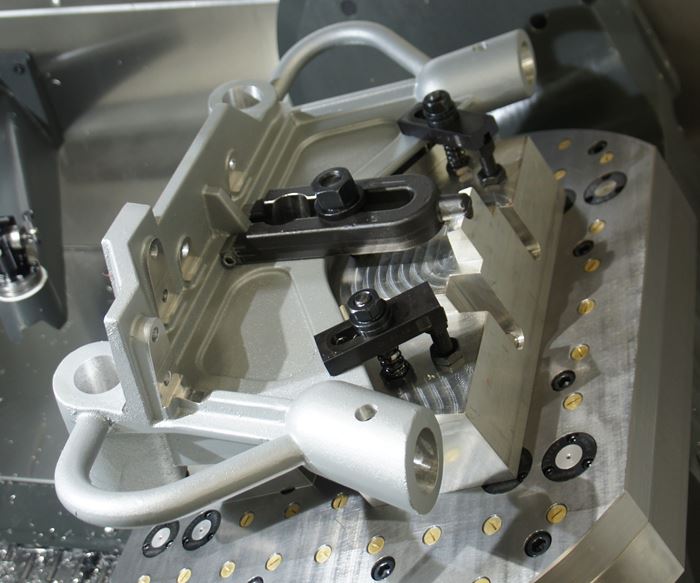

Many contract manufacturers claim to specialize in tough jobs that others reject. However, Contour Precision has chosen a particularly specific niche: low-volume, repeat jobs involving non-round, non-square milled components, particularly castings and forgings, that require custom fixtures (learn more about the company’s approach to fixture design).

Other work tends to be rejected, and for good reason. “We’ve got a bunch of tool and die makers—we can do anything—but we’ve learned that there is a cost associated with doing just anything,” Ms. Reichlin explains. “One of the biggest factors in our success has been simply understanding what we do well and being able to turn down work that does not fit us.”

“You have to make money on what you do,” adds Mark Schroeder, vice president of operations. “You have to be able to say ‘no’ to the customer. If it isn’t going to repeat, if we can’t make it more productive, if it doesn’t need special tooling—if it’s already optimized, and there’s not a lot of value we can add in manufacturing the part—then maybe it’s not for us. We are happy to make a referral.”

He adds that focusing only on the right work also ensures that resources can be devoted to value-added services that make the shop seem indispensable. These include assembly and inventory management, including storage, testing and just-in-time shipping of customers’ products.

Metrics Matter

Saying “no” requires more than just firm resolve. After the economic crash, “We became a lot more systematized,” Ms. Reichlin says. “We had to start tracking metrics in our business to help us understand where we were failing and where we were doing well.”

Consider the ratio of payroll hours versus machine production hours, a measure of output per employee. Of all the costs that go into running a machine at this shop for an hour, labor is by far the most significant and the most variable, Mr. Schroeder says. Thus, this metric plays a significant role in driving decisions such as which jobs go to which workstations, where to apply automation and who needs training in which area. (This very metric is the focus of MMS’ February, 2018 cover story, which details another shop’s implementation of a machine monitoring system.)

Price Is Not a Negotiating Tool

At Contour Precision, there’s no room for charging less or accepting less-than-ideal work just to establish a relationship. Costing is always honest and transparent, with the numbers reflecting material, consumables and other prices; the machinery used to produce the part; and the shop’s well-paid people. “We’re not out there low-balling quotes to get new business,” Ms. Reichlin says. “You have to start out quoting honestly with your team first, or you’ll just make customers angry later when you have to ask for a price increase.”

Leadership is also wary of deals involving packages of jobs, which typically contain both “winners” and “losers” in terms of profitability for the shop. In their view, all jobs stand alone, and each should be evaluated on its own merits. “In our experience, you’ll never lose the jobs you quoted too low, but you’ll eventually lose the ones you quoted too high,” Mr. Schroeder says.

FUD Comes First

This approach to costing makes sense for a shop that focuses less on per-piece costs and more on the total expense of delivering a part. For some customers, however, another concern comes first. “We may be able to bring a lot of value to the job, but we never get a chance to present that value if we don’t first deal with the FUD factor—fear, uncertainty and doubt,” he says.

Good financials demonstrate solvency and capability to upgrade technology regularly without incurring debt. From there, one key tool for reassuring risk-averse prospective customers is “Safe Launch,” a step-by-step process for starting a new job and shepherding it through to conclusion. This process helps prevent miscommunication and confusion by ensuring the customer knows exactly what to expect at every phase, from receiving the purchase order to production trial runs to packaging and final job documentation. This plan includes provisions for dealing with unexpected disruptions. The idea is that Contour Precision, not the customer, shoulders most of the work of sourcing parts with a new supplier.

“Risk outranks even price when it comes to the concerns of a big company sourcing with a smaller parts supplier,” Mr. Schroeder concludes. “The more seamless and painless we can make the entire process, the better off we are going to be and the better off the customer is going to be.”

Read Next

Rego-Fix’s Center for Machining Excellence Promotes Collaboration

The new space includes a showroom, office spaces and an auditorium that will enhance its work with its technical partners.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read More

.jpg;maxWidth=300;quality=90)