Although mistakes can be disastrous when producing complex one-offs, the time and expense involved in ensuring error-free G code can also straitjacket competitiveness. At Miltera Machining Research Corp., TruePath software from CAMplete Solutions is key to managing that delicate trade-off. By ensuring consistent, edit-free code regardless of the originating CAM system, the post-processing, verification and optimization system has saved time, improved confidence on the shop floor and eliminated the need for manual prove-outs, says Kyle Anniko, lead engineer at Miltera.

Located near CAMplete’s headquarters in Kitchener, Ontario, Miltera specializes in machining research, short-run production and turn-key applications. Work spans all industries, but most involves projects for the medical, racing, consumer products and aerospace sectors. Seven people work at the company’s 10,000-square-foot manufacturing facility, which houses various five-axis and turn-mill machines from such builders as GF AgieCharmilles, Matsuura and Nakamura-Tome (the latter two companies are represented in the United States by Methods Machine Tools).

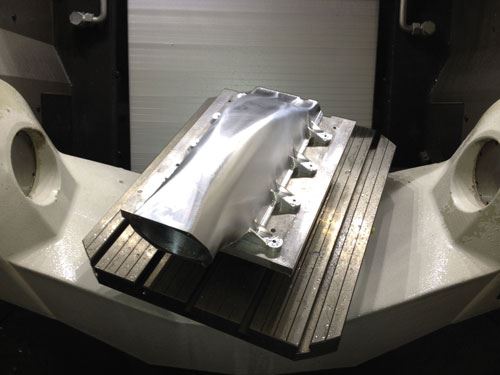

The part shown on page 108, an air intake for a Shelby Cobra GT500 engine, is a typical example of the sort of work processed on this equipment: one-offs that require high-precision, custom tooling and lengthy machining routines. Machining the intake requires removing more than 95 percent of the material from a solid, 40-kg billet of aluminum via simultaneous five-axis operations on the shop’s GF AgieCharmilles HPM 800U HD five-axis VMC. Precise positioning on the engine block and smooth surface finish on the intake’s interior are critical to avoid perturbing the airflow to the engine, and any variations from optimum geometry can directly impact performance, Mr. Anniko says. Other critical concerns include ensuring proper fixturing and avoiding part deformation.

Such parts can quickly become complicated and time-consuming. In fact, producing a single, finished Shelby Cobra GT500 engine intake can take as long as two days. The fact that the shop uses multiple CAM systems only adds to the complexity. During programming, this strategy is useful because different systems are better suited for different tasks, Mr. Anniko says. For instance, the shop appreciates one particular program for its wide range of five-axis finishing strategies. However, each CAM system requires its own unique postprocessor for each individual machine on the shop floor. Programming difficult parts is well within Miltera’s expertise, but dealing with the intricacies of five-axis posts is another matter.

As a result, the shop often lost days and even weeks to postprocessor development before it implemented TruePath. Mr. Anniko explains that generic posts supplied by software vendors often didn’t account for CNC capabilities that might differentiate Miltera’s machines from standard models, such as coordinate rotation, tool center-point control and the like. Fine-tuning any given post involved not only simple formatting changes, such as ordering codes in a certain way, but also more complex alterations, such as adding support for PLANE SPATIAL commands or NURBS interpolation. After this lengthy process, the post required testing, which tied up production. In the end, all this time and effort would result in only a single post for a single combination of machine and CAM system, and any updates to the capabilities of either would require additional postprocessor modifications.

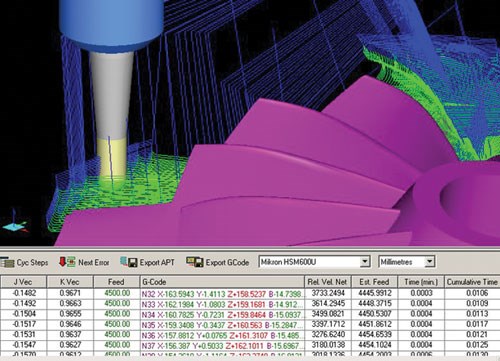

In contrast, TruePath translates input from any of the shop’s CAM systems into standard, consistent output for any machine on the shop floor. Programmers can even combine partial programs from different CAM systems as-needed with full confidence that the final G code will account for all functions of any given machine control, Mr. Anniko says. Best of all, ensuring that the actual machining routine proceeds exactly as the programmer intended requires no effort from Miltera personnel. Jeff Fritsch, product manager for TruePath developer CAMplete Solutions, explains that his company has laid much of the groundwork in postprocessor development by collaborating extensively with machine tool builders to develop out-of-the-box posts for specific models. Once installed at a user’s facility, the software further fine-tunes posts by pulling parameters and kinematics directly from each machine’s CNC.

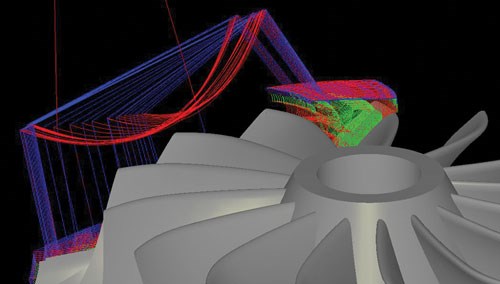

Reading machine parameters and kinematics from the CNC has implications beyond postprocessor generation. It also makes TruePath’s simulation capabilities more robust than a typical CAM system, Mr. Fritsch says. Most CAM-integrated simulation does an adequate job of simulating a tool’s motion through the material. However, these systems are limited to the internal CAM file. This results in problems like those associated with the generic postprocessors described above, wherein the CAM system doesn’t account for non-standard CNC features. In contrast, TruePath tunes the simulation to the exact machine on the shop floor, just as it does with the postprocessor. Likewise, using 3D models supplied by machine tool builders enables users to build an accurate, virtual rendition of the machining environment. This ensures that the simulation will account for aspects that CAM-integrated verification might miss, including custom tooling and fixtures, part orientation within the workzone and other factors that could cause clearance issues or other problems.

This close tie-in between the postprocessor and the simulation is particularly key for Miltera because the shop typically doesn’t have the option of scrapping and re-machining a part, nor can it typically make “one-offs” to verify machining processes, Mr. Anniko says. Additionally, the software always keeps the simulation in sync with the latest changes to the G code. This improves efficiency by enabling programmers to test different production strategies without worrying about whether their intent will be lost in translation when the program executes. Finally, in addition to postprocessor generation and simulation, TruePath enables programmers to optimize code—a capability it didn’t have before. Common optimization changes include point spacing, curve linearization and feed-rate leveling, among others.

In all, the package has provided substantial time savings, Mr. Anniko says. Programmers no longer have to spend hours working through incomplete posts, and machining proceeds exactly as intended. The shop has also become confident enough in its simulation capabilities to machine high-value parts without manual prove-outs. Optimization makes programs more efficient. This has ripple effects throughout the entire operation. For example, the shop can be more confident in moving to adopt new machines and technologies, such as a recently acquired five-axis laser ablation machine.

.png;maxWidth=45)

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)