Going to Extremes

I wrote this column in early 2008 listing machining “megatrends.” It still holds up, but because it was written before the crash, a couple of the points (on employment and currency) have acquired a prescience I never intended.Recently, I got a note from a shop I visited that included an example of another of the trends in that column: the push away from mid-sized workpieces toward more extreme workpiece sizes.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

I wrote this column in early 2008 listing machining “megatrends.” It still holds up, but because it was written before the crash, a couple of the points (on employment and currency) have acquired a prescience I never intended.

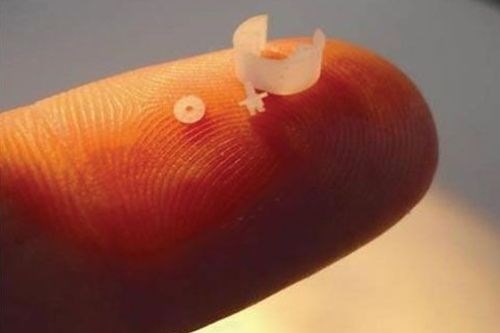

Recently, I got a note from a shop I visited that included an example of another of the trends in that column: the push away from mid-sized workpieces toward more extreme workpiece sizes. Contract manufacturers pursuing higher-value opportunities continue to develop capacity to machine parts that are either very big or very small.

The shop, KLH Industries, bought a Doosan turning center able to turn parts more than 80 inches long and 25 inches in diameter. The bigger the part, the less the competition for the work—in part because big parts are inherently difficult to send far away.

Much the same thing is true for small parts. The smaller the part, the fewer are the shops that know how to make the part effectively. For stories of job shops that migrated to smaller-scale machining, see this article and this one.

Speaking of going to extremes, here is the 1989 song by that title. Question: Just how underrated is Billy Joel? E-mail me.

.jpg;maxWidth=300;quality=90)