CAM System Drives Big Gains In Racecar Engine Porting

Racecar engines have grown increasingly more complicated as designers attempt to maximize power and performance. Every advance in machining and programming seems to be met with new demands from racecar engineers. One contract manufacturer that is more than familiar with the difficulty of keeping up with ever-evolv

Share

ECi Software Solutions, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View MoreRacecar engines have grown increasingly more complicated as designers attempt to maximize power and performance. Every advance in machining and programming seems to be met with new demands from racecar engineers. One contract manufacturer that is more than familiar with the difficulty of keeping up with ever-evolving engine designs is Kencom, Ltd. Based in Coventry, UK, the company had trouble machining inlet and exhaust ports in engine cylinder heads. This type of machining, known as porting, involves complex internal geometries with curves, tapers and tight surface finish specifications.

For years, the company handled porting jobs with three-axis milling plus two-axis positioning, a technique known as “3+2” machining. However, this strategy required multiple tool passes and resulted in inadequate surface finish. To address these issues, Kencom upgraded its existing Edgecam CAM system to support simultaneous five-axis machining. In addition to providing a tenfold improvement in surface finish, this new capability has enabled the company to cut programming time by half and machining time by two-thirds.

With 35 employees, Kencom specializes in machining cast components, particularly light alloys, in prototype and low-volume production batches for the automotive and aerospace markets. It also machines prototypes and aerospace components from solid billet. The shop is equipped with 15 CNC machine tools, including three-axis VMCs, five-axis VMCs and four-axis, twin-pallet HMCs.. Blocks and heads for racecar engines represent about a fifth of the company’s business.

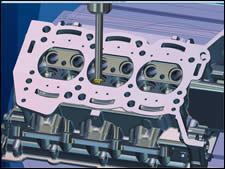

CNC programmer Lee Sambrook programs most porting jobs on a five-axis Mazak Variaxis 630 with a Mazatrol CNC. The trunnion-type machine is equipped with a Renishaw touch-probe for on-machine verification. The company also uses this machine for the remainder of the cylinder head features such as exhaust ports and combustion chambers.

Kencom’s first five-axis porting project involved a 1.3-liter engine that produces more than 200 brake horsepower. With dimensional tolerances of about 0.004 inch, the engine’s intake ports averaged about 2.4 inches long and between 0.787 and 1.18 inches in diameter. Overall, these particular heads measured 17 by 12 by 5 inches.

“Intake ports are complex, and they’re a real challenge to machine well,” Mr. Sambrook says. He describes the ports as “banana-shaped,” with curves varying from a 10-degree change in the axis to as much as 30 degrees. The most important role of intake ports, which are cast into aluminum cylinder heads, is to ensure optimum mixing of fuel and air going into the combustion chamber. Quality surface finishes are critical to avoid unnecessary turbulence, which can slow the velocity of the air/fuel mixture as it is sucked into the engine and limit maximum power.

According to Mr. Sambrook, Kencom moved to full five-axis motion because 3+2 machining “just wasn’t cutting it” in terms of achieving the required surface finishes on the ports. While 3+2 machining is limited to linear interpolation, full five-axis machining uses circular interpolation. “You always get better machined surfaces with circular interpolation,” he says.

The problem with linear interpolation for is that all toolpaths—including those used to cut contoured surfaces—must be defined as straight lines. To avoid creating visible blend lines at the meeting points of curved surfaces, the shop often had to take as many as 15 machining passes to “smooth out” the contoured shape. In addition, the 3+2 method resulted in inconsistent cutter loads on the tool, which led to inconsistent material removal on various surfaces. “The difference meant some surfaces were missed, while other surfaces were machined three to four microns too much,” Mr. Sambrook says.

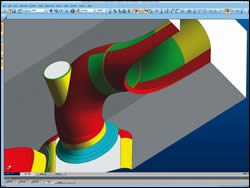

To address these difficulties, Kencom added Edgecam’s simultaneous five-axis machining module to its existing Professional Milling software package. Full five-axis capability has enabled the shop to realize a tenfold improvement in surface finish. Mr. Sambrook speculates that this improvement adds as much as 10 percent to a given engine’s brake horsepower, which can provide a winning edge in a close race. Moreover, machining time for a typical cylinder head, ports and all, has dropped from 3 hours to 1 hour. “With 3+2, you are cutting air as much as 80 percent of the time,” Mr. Sambrook says. “Plus, 3+2 requires a minimum of three passes to do what you can do with one five-axis pass.”

In addition to the five-axis module, Kencom invested in Edgecam’s Solid Machinist, a solid modeling application designed to provide the integration needed for automatic part-design updates. Solid Machinist can load native solid models from Unigraphics, Pro/Engineer, Catia and other applications via traditional IGES or STEP translation. The software’s true associativity to imported solid models allows the company to save time via automatic CAM program upgrades when customers modify designs in the middle of the CAM process. “We can do all this without having to rework the geometry. Otherwise, we risk losing business,” Mr. Sambrook says.

Also, Mr. Sambrook worked with Edgecam application engineers to develop custom automation routines that contain best-practice machining techniques for porting. Along with five-axis capability and tight integration with Solid Machinist, these automation routines have helped Kencom reduce programming time by 50 percent.

“For two or three years, we skirted around the edges of our Mazak machines’ capabilities with 3+2 machining,” Mr. Sambrook says. “With full five-axis programming, we have at last been able to achieve the full potential of these machines with a programming system we know and trust.”

Related Content

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreCan ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)