Building an Automation Solution From the Ground Up

Sponsored ContentIMTS 2022 provides visitors the opportunity to meet with product experts to design automation solutions from scratch.

Share

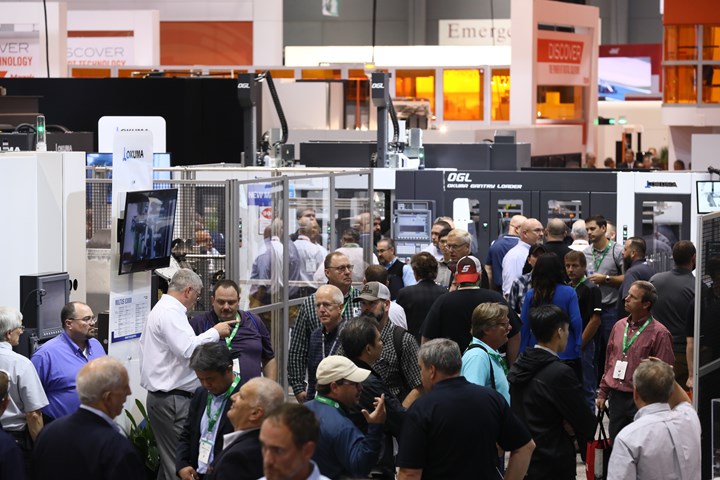

IMTS 2022 – the International Manufacturing Technology Show – is quickly approaching, and many shop owners may be wondering how it could help them with their business. One of the major draws to IMTS is the ability to discuss solutions with experts who specialize in their company’s products.

This year, IMTS is emphasizing the rise of single-setup automation – an approach to automation that, as the name suggests, enables the shop to perform all machining operations in a single setup. But how would a shop owner looking to dip their toes into automation benefit from IMTS? Let’s find out.

Automation Starts With a Part

At IMTS, shop owners have the opportunity to speak with hundreds of product experts, providing the opportunity to learn about the technology they wish to invest in.

The first thing to know about automation is that the automation system must be designed with a job in mind. There is no single automation solution that is perfect for every application, so a shop must begin by looking at the part.

Take a turning application. If it is a small diameter part with a handful of OD operations, a bar feeder and tool turret will get the job done. What if it’s a much larger part with both ID and OD operations, plus some milled features and off-center drilling? Depending on the specifics, the solution could be as varied as a quick-change collet system from Schunk (IMTS booth: 433219) in the West Building to a Mazak (IMTS booth: 215128, South Building) QT-series turning machine with a second spindle. The benefit of coming to IMTS when you are searching for an automation solution is that so long as you know the parts, IMTS exhibitors will be eager to discuss solutions.

This is the key to IMTS’s success: Exhibitors staff their booths with product experts who can assist you in designing your automation system. These experts will listen to what you need and discuss what solutions they can offer, walking you through the benefits and drawbacks of each solution they have available. With that information in hand, you can then weigh the benefits and costs to decide which solution works for your application and your shop.

You Need Robots? We Got Robots

The classic example of automation is, of course, robotics. But how should a shop incorporate robots or other material handling systems into a machining cell? There are so many decisions to make: cobots or fenced-off robots? Buy off-the-shelf or develop a custom system? What grippers will it need? Once again, IMTS is there to help. The chief draw of the show is that you can take your time discussing your shop’s needs with experts who are there to keep you informed.

Large robots like this FANUC arm must be cordoned off from other areas of a machine shop, but their speed and strength may make them worth the space.

Perhaps you own a job shop that needs a simple robot arm to lift parts, but you only employ a handful of machinists, and no one has experience programming robots. A trip to the North Building will put you in contact with Universal Robots (IMTS booth: 236861) and Yaskawa (IMTS booth: 215016 and 236601), both of which produce cobots that fit in precisely that niche. Cobots are designed to be simple to program without prior skills, and they can operate safely next to human workers without the need for safety cages.

Or maybe you have the room and workload to justify a fully automated cell. Both Yaskawa and FANUC (IMTS booth: 338919) (across the hallway in the South Building) provide full-speed robotic cells that can be customized to work with any machine tool. These robots move faster and can lift heavier loads, but they must be cordoned off from human workers and require more advanced programming. Both approaches to automation have benefits and drawbacks, and weighing these out with the experts can help you come to a decision.

Cobots like those by Universal Robots are designed to safely work alongside human workers. They make loading and unloading a variety of parts easier and are simple to program.

Of course, the decision you make when it comes to robotics get more granular. Maybe the job you have in mind will benefit from one of Servo-Robot’s (IMTS booth: 236171) vision systems in the North Building. Maybe you think a cobot will do the job, but after discussing it with the experts you will lean more toward a fully automated cell. Maybe you were looking at an Okuma (IMTS booth: 338500) in the South Building and found the company’s Armroid system fits your needs and space best. In all cases, speaking with product experts will help dial into the specific setup that would serve you best.

The Key to Automation is Everything

Of course, automation is not just about robots. Bar feeders, pallet systems, multi-spindle machines, Swiss-style lathes and other solutions will all be shown at IMTS. Just as important, the technologies that assist and enable the actual part movers will also be on display.

There are many paths toward automating your shop, and IMTS provides you with the opportunity to explore these options with experts in the technology.

For example, any shop interested in lights-out manufacturing will have to invest in some version of in-process metrology such as the systems provided by Blum-Novotest (IMTS booth: 135532) in the East Building. Additionally, a trip to the West Building to discuss which cutting tools will be best for their material needs and machining style, not to mention the tool life to consider. On top of that, the proper toolholder is necessary if that fancy end mill is going to be worth its cost.

There are additional technologies to consider. Can your shop incorporate hybrid manufacturing – machines that use both additive and subtractive processes – into production? How will you approach automation in a grinding application? Five-axis? Gearmaking? Every process requires specific considerations, and there are many companies at IMTS whose solutions have those considerations in mind.

Automation has never been about simply slapping a gripping arm on the side of a machine tool. It is a holistic approach to manufacturing that requires you to consider the entire production process to deliver the best results. What makes IMTS special is that all of these varied companies with solutions necessary to develop a complete automated manufacturing cell are in one place and eager to help you improve your shop.

Find more at IMTS 2022

- Use the IMTS Show Planner to keep track of the booths you’d like to be sure to visit and even set up appointments to review your most complex parts. Go to IMTS.com.

- Find out what other manufacturers have discovered at IMTS to achieve great efficiencies, Visit IMTS.com/Find.

- Enhance your knowledge on automation, visit IMTS.com/Conferences.

IMTS 2022: Robot Roadmap. AMT’s Tech Analyst, Stephen LaMarca, and Director, Technology, Benjamin Moses, offer to hold your hand as they discuss finding your way around IMTS 2022 in search of automation and robotics! Check out more episodes of AMT’s TechTrends Podcasts at AMTonline.org.