Automating Grinding Setups For Root Form Tools

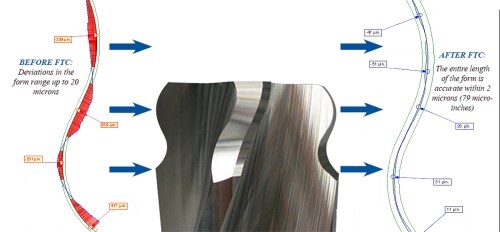

An automated Form Tool Compensation system offers a streamlined way to set up root form cutter jobs on grinding machines while ensuring ground profile accuracy to as little as 2 microns.

Root form slots found in turbine rotors are characterized by complex contours and precise dimensions. “Christmas tree” form tools used to cut those intricate slots must be precisely ground so no portion of their profile pushes through their tight tolerance band. Consequently, setting up grinding machines to repeatedly deliver quality root form tools is often challenging and time-consuming.

These setups typically involve grinding a trial tool, measuring the tool to identify the portions of the profile that are out of tolerance, and manually tweaking the machine and/or part program to compensate for grinding discrepancies. Depending on the application, this setup procedure can take hours.

The automated Form Tool Compensation (FTC) system developed by Walter (a United Grinding company) offers a more streamlined way to set up these jobs while ensuring ground profile accuracy to as little as 2 microns. By shortening, simplifying and automating the setup process, this technology minimizes turnaround time for manufacturers currently producing such complex root form tools and opens up opportunities for those hoping to enter this market.

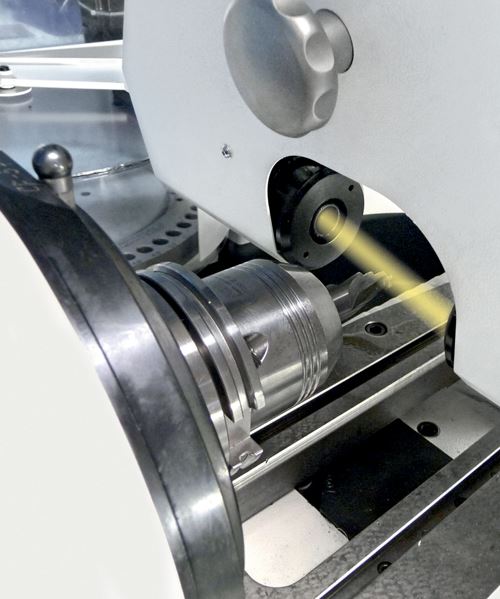

The FTC system is available for use with the company’s Helitronic grinding machines and supports three tool grinding methods: faceted relief, cam relief and cylindrical grinding. The heart of the system is measurement/program compensation software that links the grinding machine and a tool measuring device. Tool measurement can be performed using one of the company’s standalone Helicheck scanning machines or a portable, on-machine scanning unit Walter recently introduced.

After a preliminary tool is ground to its upper tolerance, the measuring device (either a Helicheck or the on-machine scanning unit) scans the tool’s entire profile without any operator involvement. (It takes 5 minutes to scan a 60-mm profile.) The FTC software then compares the measured profile to the CAD model and automatically creates and sends compensation corrections to the grinding machine’s control. At this point, the grinding machine is ready for a production run.

When a Helicheck is used as the accompanying measuring device, FTC can deliver a ground profile accuracy within 2 microns. When the on-machine scanning unit is used, FTC is only minimally less accurate at 3 microns. However, the on-machine scanning unit can be used on multiple Helitronic machines and costs less than standalone equipment. The on-machine measuring unit consists of a high speed CCD camera coupled with a collimated LED backlight. The backlight allows the camera to reliably distinguish a tool’s cutting edge regardless of tool material or surface finish. The unit installs in the grinding machine’s head in less than one minute without calibration thanks to a self-centering interface. It uses air nozzles to automatically clean tools before performing its scanning routines. After the unit measures a tool, it is removed to allow grinding to be performed.

The on-machine FTC version is offered as an option on new Helitronic machines. It currently can’t be adapted for use with older Helitronic machines because a different grinding head design is needed to allow the head to accept the scanning unit.

Related Content

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

-

How to Choose the Correct Measuring Tool for Any Application

There are many options to choose from when deciding on a dimensional measurement tool. Consider these application-based factors when selecting a measurement solution.

-

Rethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

.jpg;maxWidth=300;quality=90)