A Tale Of Two Shows

Recent trade shows in Spain and in France displayed latest technologies for accurately machining extremely large components as well as really small ones.

The distance separating the BIEMH trade show in northern Spain and the Simodec show in eastern France is not all that significant. The types of machine tools displayed at the biennial shows in early March, however, were on opposite sides of the machining spectrum.

Spain’s BIEMH, held in the city of Bilbao, is famous for presenting equipment with the capacity to accurately machine huge workpieces used in a variety of industries. Conversely, Simodec (the International Trade Fair For Screw-Cutting Machine Tools) focuses on equipment used for high-volume production of small, precision components. So I began the first week of March checking out a 16,000-pound hub casting fixtured to a traveling-column machine, and ended it by watching simultaneous machining of Rolex watch stems from six pieces of bar stock.

What I also found interesting at these shows was the continued trend of machine tool designs integrating aesthetics as well as accuracy. The machine tool builders clearly recognize that ergonomic design elements improve not only the attractiveness of a machine, but also user-friendliness and overall functionality.

Although it’s impossible to capture all that two trade shows have to offer in one article, this piece offers a taste of what these contrasting European shows brought to the table.

Stop One: Big Machines In Spain

The 2008 edition of BIEMH marked the show’s 25th anniversary and was the third time it was held at the Bilbao Exhibition Centre (BEC). The BEC co-organizes the event with AFM—the Spanish Association of Machine Tool Manufacturers. Approximately 50,700 visitors attended this year’s show that featured 1,761 exhibiting companies from 36 countries.

One industry application that clearly stood out at the show was energy production via wind turbines. Nearly every major Spanish machine tool builder touted features of their machines that made them well-suited for producing wind-turbine components, such as hubs, tower sections, tower flanges and gear boxes. Wind turbines are not only increasing in usage for energy production in Europe and the United States, but are becoming more massive. The machines that many of the Spanish manufacturers offer are not only appropriately sized for these applications, but typically offer a number of interchangeable machining heads to provide the flexibility to perform operations such as milling, boring, facing and so on in one set up.

One example is Soraluce’s floor-type, traveling column machine that offers maximum X- and Y-axis travel of 30 meters and 5.3 meters, respectively. The turbine hub casting loaded on its rotary table at the show weighed 16,000 pounds after requisite facing, drilling and tapping operations. Recognizing the growing demand for wind turbines, Soraluce has opened a facility near Pamplona to cast and machine these hubs for wind-turbine OEMs.

Some of the large machines that can use multiple heads, such as Juaristi’s MX Series traveling column machines and CorreaAnayak’s Supra line, offer optional, automatic head-changing systems. The heads are stored in a “magazine” when not being used, and head change-out functions similarly to an automatic tool changer on a machine tool.

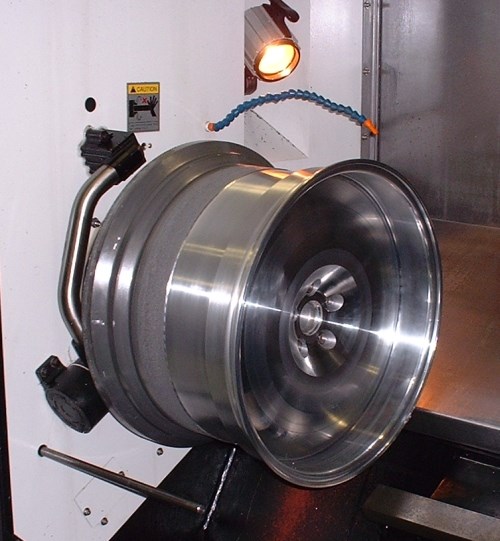

Large-scale turning equipment was also represented at the show. The Goratu Group, which is made up of Gemenis and Langun brands, displayed its big Gemenis GHT 11 horizontal lathe that finds use in the wind turbine, oil and paper industries. It offers swing over bed of 2 meters, spindle bore diameter of 162 mm and maximum distance between centers of 24 meters.

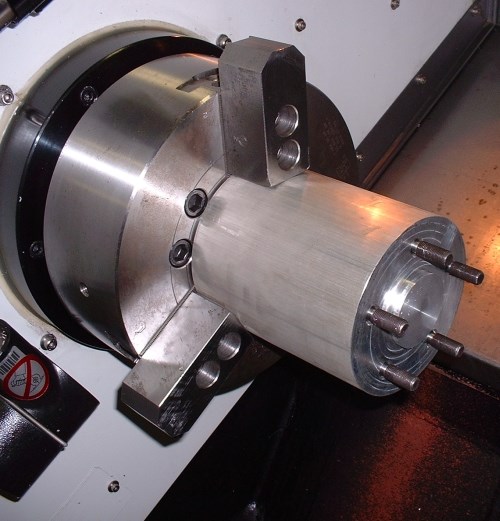

For applications in which vertical turning makes more sense, Bost’s VTL 16C offers a maximum turning diameter of 1.6 meters and workpiece weight of 15 metric tons. The 16C version at the show is the smallest of the company’s VTL platform—its largest model offers turning diameter of 2.8 meters. Optional equipment makes it possible for these VTLs to perform turning, milling, drilling and grinding operations in a single set up.

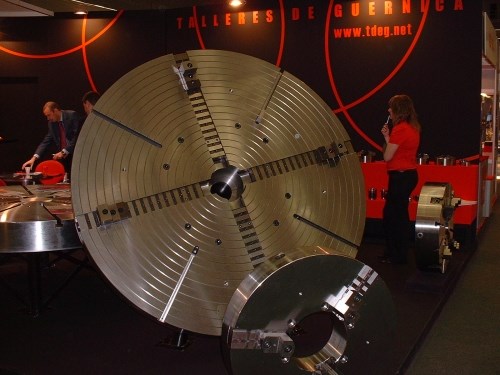

Talleres De Guernica (T de G) displayed a variety of its large hydraulic and pneumatic power chucks. The chuck shown on page XX can hold workpieces with diameters up to 2 meters. A T de G representative at the show said the company was quoting a 4.5 meter chuck for a company machining wind turbine tower segments. That chuck would be the largest the company has produced to date. Many of the Spanish machine component makers such as T de G are represented by AMT, which is Spain’s association for machine tool accessories, components and cutting tools.

Stop Two: Small Machines In France

The Simodec show in France dates back to 1954. It is held in the heart of the French Alps in Arve Valley, and is organized by Foire de la Haute-Savoie Mont-Blanc. The 2008 edition attracted approximately 14,900 visitors, which is 11 percent more than the 2006 show. Like BIEMH, the Simodec show gains greater attention from the international metalworking community with each edition.

The beautiful Arve Valley contains the world’s highest concentration of screw cutting shops, making this area not only an attractive place to visit, but spot-on-appropriate for a show focused on precision machining of small parts. The area screw machine shops have recovered a good amount of previously outsourced work by focusing on production of highly complex components, according to Simodec organizers. Such progressive shops will require advanced machining technologies to continue that trend, and that’s exactly what was featured at the show.

For example, Willemin displayed its bar-fed, W-408 MT machine that can perform both turning and five-axis milling operations. The bar feeder allows long stretches of untended operation while reducing typical workpiece fixturing and setup hassles. The machine at the show was producing the complex part at the right. The part, which includes an intricate, serrated jaw for a medical clamp, was produced from stainless steel bar stock in 22 minutes.

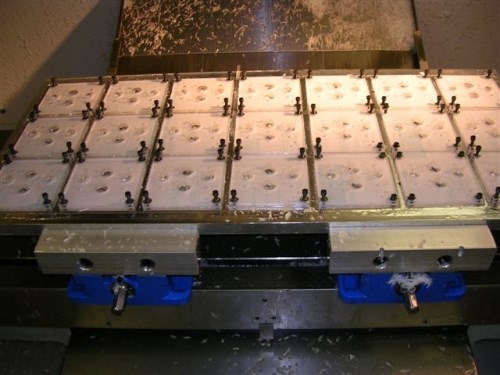

Emissa’s WinFlex 300 MultiBar machine, demonstrated production of multiple stems for Rolex watches. The compact, three-axis machine has a revolver turret head with 8 stations, and was outfitted with bar feeding system that accommodated 6 pieces of bar stock for simultaneous machining of 6 stems. After machining on 5 sides of each part is completed, a backworking device grips all parts as they are sawn from the bar stock to allow machining of their final side.

Index displayed its Speedline A100, which is a compact, single-spindle version of the company’s MS line of multi-spindles. The A-100 has multiple tool carriers located around a fixed spindle that accepts bar stock up to 42 mm in diameter (90 mm for the A-200 machine version). Other new single-spindle lathes included the Tornos Micro 7 machine that is said to offer an alternative to cam-type machines. The Micro 7 is designed to turn part diameters of 7 mm and smaller to an accuracy of +/-2 microns. In addition, rotary transfer machine builder Wirth & Gruffat unveiled its new TAM 7.40 sliding headstock machine developed for watchmaking and other applications requiring tiny components. The single-spindle lathe is available in a number of configurations, including self-generating milling, 3-tool turret head and counter spindle versions.

Bar feeders are a staple for high-volume production of turned parts from bar stock. Iemca, one company that manufactures bar feeders, recognizes that automation is also required for high-volume machining of small forgings and castings. Its new Automata gantry parts loader and storage unit permits long stretches of untended machining of such parts on lathes, mills and grinding machines. The device features a gantry loader with X- and Y-axis strokes measuring 2.5 meters and 1.2 meters, respectively, and is available with either stacking or palletizing parts storage systems.

Finally, the Escomatic 646 machine demonstrated the company’s rotating-tool-head design that permits machining of small, round parts from non-rotating wire. The workpiece stock does not rotate, so small diameters can be fed from a coil (larger stock can be fed as bars).

Read Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)