A New Mechanism For Tool Changes

After 3 years of lab tests, this tooling manfacturer has developed an entirely new type of spindle cartridge that addresses some drawbacks of the conventional design. The company's gas spring clamping system uses gas pressure to exert gripping force on the toolholder.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Since the advent of automatic tool changers, a spring pack actuated by a drawbar has been the standard mechanism for clamping toolholders into a machine tool spindle. A spring pack consists of a stack of Belleville washers—specialized types of spring washers that provide substantial gripping force when compressed. Like any spring mechanism, however, a conventional spindle cartridge loses a significant portion of its strength after repeated use. Depending on the total number of tool-change cycles, this reduction in clamping force may be 30 percent or more.

Higher spindle speeds have increased the importance of accurate balancing for cutting tools, toolholders and related components. The Belleville washers in mechanical spring packs can present problems in this regard, because they shift away from the center axis of the cartridge during clamping and unclamping. This characteristic can affect the balance of the cartridge, and the spring pack’s weight amplifies the effect of any imbalance.

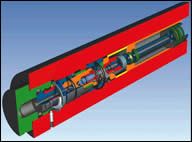

After 3 years of lab tests, Sandvik Coromant has developed an entirely new type of spindle cartridge that addresses some drawbacks of the conventional design. The company’s gas spring clamping system uses gas pressure to exert gripping force on the toolholder. It incorporates a rod-and-piston structure that is connected to the drawbar. The cylinder bore contains high-pressure nitrogen gas, and the internal gas pressure is equal on either side of the piston. This pressure serves the same purpose as the spring pack in a conventional spindle cartridge. As the piston rod is compressed, gas is displaced inside the cylinder. This stores additional energy that generates the clamping forces.

Compared to a conventional spring-pack cartridge with equivalent clamping force, a gas spring is more compact in size and lighter in weight. Furthermore, the cartridge’s symmetrical design eliminates balancing variations. In terms of durability, the gas spring will lose only 5 percent of its original clamping force after 1 million cycles. In contrast, spring-pack mechanisms can lose up to 50 percent of their clamping force at the same stage of use. For machine tool builders, a gas spring is easier to assemble into a spindle cartridge than a spring pack.

Extensive testing by the Sandvik Coromant lab has shown that, regardless of spindle speeds or machining conditions, the gas spring cylinder has not experienced any significant failures. The company has offered this product to all of the principal machine tool builders, and some of these firms have used their machining centers to conduct field-tests. One some of their multi-tasking machines, builders such as Index Corporation (Shelton, Connecticut) and Daewoo Heavy Industries (West Caldwell, New Jersey) already offer Coromant Capto spindles with gas spring clamping systems.

.png;maxWidth=150)

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)