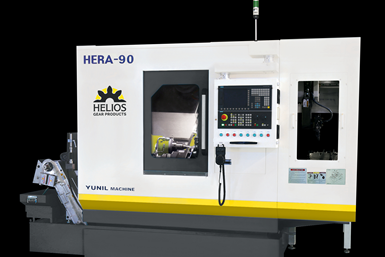

Helios Introduces Gear Hobbing Machine

The Hera 90-W solution for long-shaft horizontal hobbing is designed to offer an extended machine bed and axial travel.

Share

Helios has added the 90-W configuration to its Hera 90 production line. The Hera 90-W is designed to equip manufacturers with a high-quality, quick-delivery, domestically supported solution for long-shaft horizontal hobbing.

The Helios Hera 90-W is rated at 3 module (8.5 diametric pitch) for parts up to 90 mm (3.54 in) diameter. The 90-W can be configured to optionally load parts with lengths up to 600 mm (23.62 in), 700 mm (27.56 in) or greater. The machine’s axial travel (hobbing length) covers nearly the maximum loadable part length. According to the company, this enables easy hobbing of long shaft parts with gears on opposite ends — especially when the gears must maintain a timed relationship.

For shorter workpieces, the machine’s tailstock design clamps workpieces as close as 200 mm (7.68 in) from the work spindle face. Other standard features of the Helios Hera 90 are included with the 90-W: FANUC CNC, complete dialog programming, 6,000-rpm hob head, high-helix cutting (for worm hobbing and milling), 160-mm (6.3 in) hob shift, bevel gear cutting and more.

The machine is designed to offer gear manufacturers an extended machine bed and axial travel, making the machine well suited for long-shaft, small diameter workpieces. It is particularly applicable for manufacturers of powertrain shafts for small to medium vehicles and those workpieces with multiple, timed splines and/or gears, according to the company.

.JPG;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)