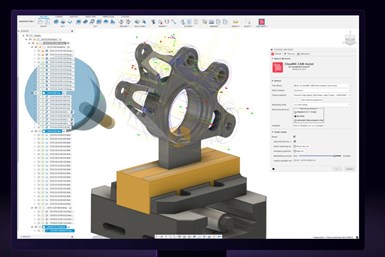

CloudNC CAM Software Enhances 3+2-Axis Toolpath Programming

CAM Assist uses AI to generate intuitive machining strategies in minutes or seconds, depending on complexity.

CloudNC has announced that its CAM Assist solution can now create programming strategies and tool paths with AI for 3+2-axis CNC machines.

The new upgrade means CAM Assist can now provide strategies and tool paths for 3+2-axis components, enabling many more manufacturers to benefit from CAM Assist’s efficiency gains.

CAM Assist uses advanced computer science techniques and AI to generate intuitive machining strategies in minutes or seconds, depending on complexity, which could take CNC machine programmers hours or even days to manually create.

As a result, the amount of time it takes to program a CNC machine to make a component is greatly reduced, compared to the previous manual programming process, as is the time spent to estimate how much a new component will cost to program. This enables manufacturers using CAM Assist to raise productivity and shorten lead times, while also estimating for more work, more quickly. According to the company, CAM Assist can save an average workshop over 300 hours of programming and estimating time per year.

Andy Cheadle, chief technology officer at CloudNC, says, “This upgrade is not only a huge step forward in making CAM Assist even more useful for manufacturers around the world, but it is also an incredible technical achievement. From an R&D perspective, 3+2-axis support is exceptionally challenging, as the extra elements it involves introduce more potential ways of making every feature of every component, by several orders of magnitude.”

CAM Assist is available for Autodesk Fusion today. CloudNC is currently undergoing beta testing in other packages, and expects to launch solutions for those later in 2024.

Related Content

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

.jpg;maxWidth=300;quality=90)