Look for CNCs with Five-Axis Machining Features

The leading machine builders have also added a variety control features that can aid setup, simplify programming, enhance quality and improve safety. These advancements include:

Collision avoidance software in a CNC can apply a digital model of the entire machining setup to head off crashes before they occur.

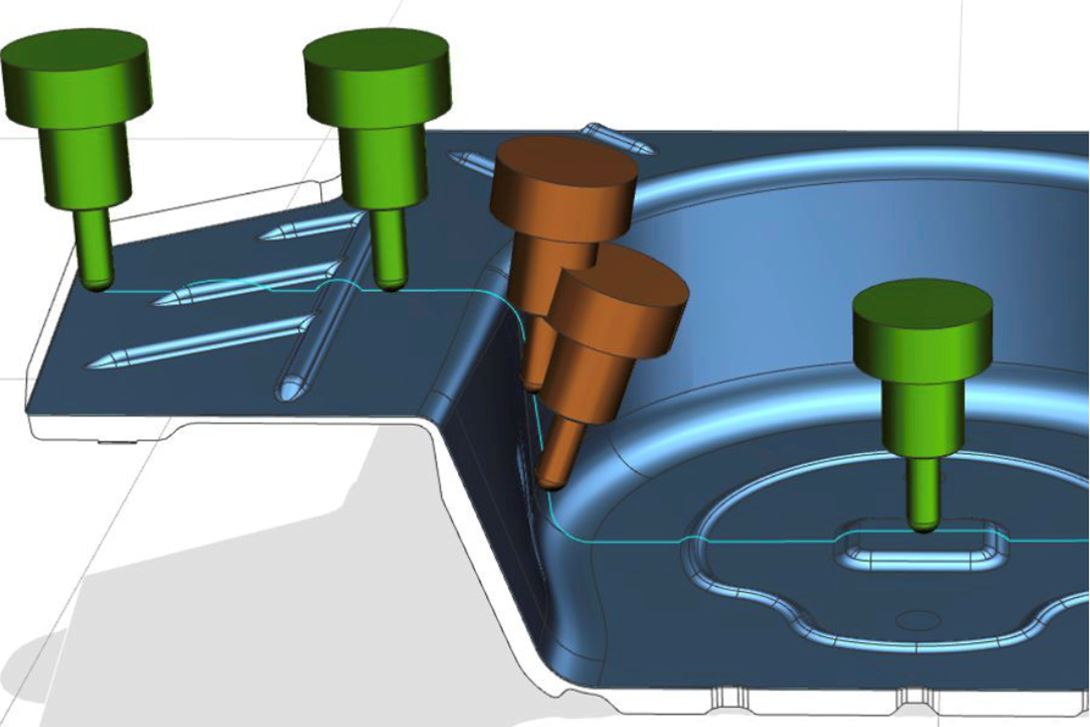

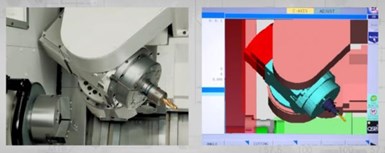

Collision Avoidance: Because of the dynamic nature of moving both the spindle and the workpiece in a five-axis environment, unintended tool, workpiece and fixture collisions are a real danger. Control resident features such as Makino’s Collision Safe Guard (CSG) or Okuma’s Collision Avoidance System (CAS) can monitor the part program for possible crashes in real time. You can even import a Vericut file into the CNC which then replicates the full simulation in the machine control and shuts down the machine before a crash occurs.

Tool Center Point Control: This function on CNCs controls the movement of each axis by automatically adding the tool length offset amount to the toolpath program. It also controls the feed rate of each axis so that the tool center point moves along the part at the specified feed rate. With this function tool rotational centers don’t have to be considered when programming the part.

Toolpath Smoothing: “Lookahead” technology has been around a while where the CNC scans ahead in an active part program and dynamically adjusts the feed rate for tight corners and curves to maintain a more accurate toolpath. Today’s best CNC’s take that capability to a whole new level allowing very accurate five-axis machining at much higher feed rates while generating very smooth cuts and blends. This capability can both dramatically reduce cycle times and improve surface finishes.

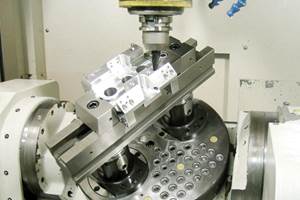

Automatic Workpiece Offsetting: Some controls include automatic probing routines and find the actual location and orientation of the workpiece or fixture, and set 3D workpiece offsets accordingly.

Nano Smoothing: This FANUC feature activates real-time spline interpolation to recreate the smooth curve originally defined by the CAD system from the line segments modeled by the CAM system, improving surface finish and processing speed.