What’s “Hydroviscous” Spindle Damping?

GMN's spindle technology uses "hydroviscous" damping to reduce natural vibrations on machine tools and grinding machines.

Natural vibrations within the spindle of a machine tool or grinding machine can limit cutting depths, reduce material removal rates and diminish surface finish quality. Insufficient damping of natural vibrations combined with high machining forces can result in rough, partly scratched workpiece surfaces, uneven cutting edges, widened grooves and even spindle failure.

GMN, a German manufacturer of machine spindles, precision ball bearings, freewheel clutches and non-contact seals, has developed new spindle technology that is said to mitigate these issues by reducing natural vibrations as much as 65 percent compared to conventional designs. Dr.-Ing. Bernd Möller, Head of Development & Construction at GMN, says the company’s hydroviscous damping (HVD) technology offers improved dynamic stiffness for high-speed spindles through enhanced damping of natural vibrations, thereby improving a spindle’s dynamic stiffness in the axial direction as much as 135 percent for rough- and finish-milling work, as well as grinding operations.

GMN uses the term “hydroviscous” to express that viscous damping is being applied to a ball bearing spindle by means of a hydraulic system (i.e. a hydrostatic bearing), Dr.-Ing. Möller explains. The company chose this unique expression to distinguish it from more common nomenclature such as “viscous damping,” which is generally used to identify a physical effect such as structural damping, and “hydrostatic bearing,” because “static” is a misleading description of HVD technology’s targeted dynamic effect.

Dr.-Ing. Möller says the goal of developing HVD technology was to combine the advantages of ball-bearing and hydrostatic-bearing designs. “Ball bearings have low-friction, high-speed capability and are essentially insensitive to high overload,” he explains. “It is possible to achieve good spindle stiffness with them, but damping is quite low. This is why hydrostatic spindle bearings are often used when very high accuracy and low vibration are needed. However, their drawbacks include frictional losses at high speeds, higher cost and the need for an elaborate recirculating system for the hydrostatic bearing system.”

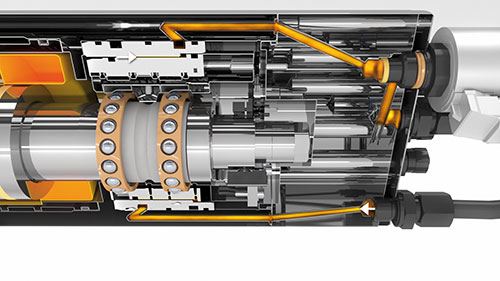

Spindles with HVD technology use a linear hydrostatic bearing the company developed for the floating-bearing side of the spindle to add viscous damping to the ball-bearing arrangement. In addition, HVD uses an unmodified front-bearing design to achieve high spindle stiffness, too.

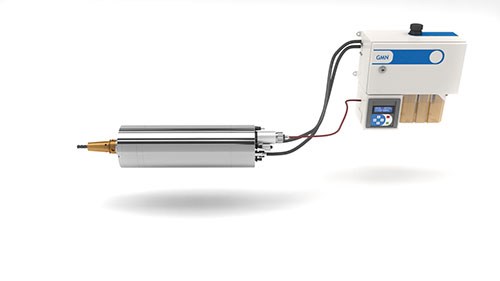

High-speed HVD spindles are independently driven by a compact, dedicated hydraulic power unit. Unlike common hydrostatic bearings, HVD linear bearings have lower requirements for oil supply, oil flow rates and electrical power. In addition, the spindle’s bearing preload can be controlled via the oil pressure. In this way, the rigidity of the spindle can be modified and optimized depending on machining task and speed, as well as the cutting tool to be used. For example, increasing the bearing preload can improve spindle performance at lower rotational speeds. However, in many cases, a constant-pressure setup is sufficient, especially when dialed-in for high-volume machining applications.

GMN spindles with HVD technology are available in a range of spindle interfaces offering speeds as high as 90,000 rpm for milling and ID grinding. Lower-rpm spindles are suitable for OD grinding. Dr.-Ing. Möller says that, while machine OEMs were the company’s primary target for this technology, end users, particularly those in the automotive and aerospace industries, have also shown interest in retrofitting their existing machining equipment with HVD spindles, which is made easier because those spindles are structurally identical to the company’s standard models.

Read Next

Increasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read MoreIMTS 2024: Trends & Takeaways From the Modern Machine Shop Editorial Team

The Modern Machine Shop editorial team highlights their takeaways from IMTS 2024 in a video recap.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read More