What It Takes to Do Unattended Wire EDM

The promise of running a wire EDM for long stretches without much operator attention is enticing, but many shops never manage to pull this off. Here are tips to make it happen, as offered by Mark Cicchetti, EDM technical director for Absolute Machine Tool’s Accutex EDM product line.

Share

Using an energized wire to slice through metal is the essence of the wire electrical discharge machining (EDM) process. Synchronized computer control of the machine’s axes enables it to cut intricate shapes that form the periphery of the workpiece or contoured openings within. Following a complex path in a steady, highly controlled manner is a very efficient method to produce these shapes in materials that might otherwise be difficult or impossible to machine, although “time in the cut” may stretch for many hours.

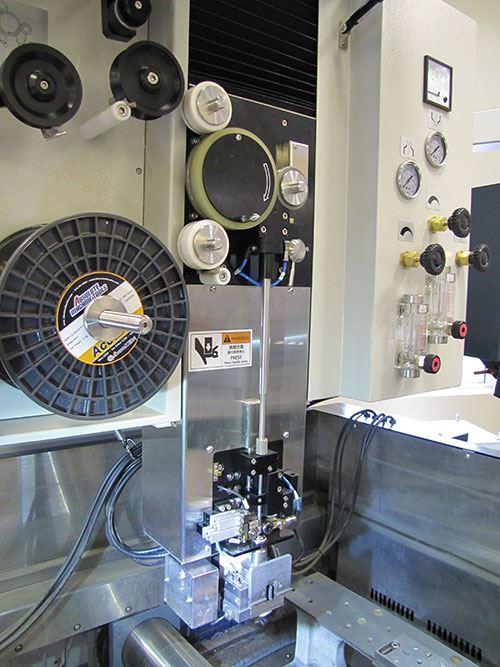

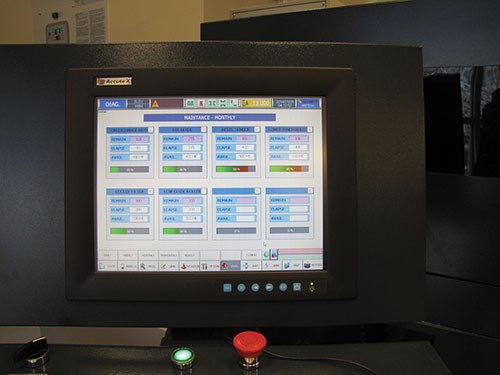

Today’s typical wire machine offers standard or optional features that enable it to operate for extended periods of time without the close attention of an operator. These features include automatic wire threaders, tooling fixtures for multiple part setups, sensing and feedback systems for adaptive control, and advanced electronics.

The prospect of exploiting this capability for unattended operation often figures prominently in a shop’s justification for acquiring this technology, whether by first-time or experienced users of wire EDM. However, many of these shops fail to take full advantage of wire EDM’s inherent potential for round-the-clock operation. Somehow, a shop may never manage to muster the wherewithal to produce good parts on the wire machine during times when the workforce is away. As a result, much of the substantial earning power represented by unattended operation of the wire EDM process is lost. Frustrated and disappointed, some shops give up on in-house wire cutting, sell the machine and settle for sending the work out to a subcontractor.

In his career as a wire EDM specialist and sales engineer, Mark Cicchetti has seen this situation too often, and he believes it can and should always be avoided. Now serving as EDM technical director for Absolute Machine Tool’s Accutex EDM product line (Mason, Ohio) Mr. Cicchetti has developed a proactive approach to make sure that buyers of wire machines from Absolute have the best chance to fully implement unattended operation of the wire EDM process and maximize the return on their investment.

“There’s no magic or mystery to it,” he says. “Any shop can master the necessary concepts and instill the discipline to make it a dependable routine.” In fact, he says, the experience is likely to lead to further efforts to make other machining processes available for lights-out operation. “Wire EDM is a good place to start the journey to full automation in the machine shop,” he says. Even for shops that do not find a place for wire EDM in their operations, a look at what it takes to implement unattended wire EDM can offer valuable lessons about managing the move to automation.

Have a Plan, a Real Plan

To get ready for unattended wire EDM, a company needs a plan. “This is the first thing a company must do, and the plan has to be complete, detailed and specific,” Mr. Cicchetti of Absolute advises. This plan should be based on research to make sure that provisions for unattended operation are included in the machine, the tooling, the programming software and the shop infrastructure (especially its communication/messaging network).

The plan needs to be documented and copies shared with everyone in the shop that will be involved in EDM operations, including the engineering and sales staff. “Input and buy-in from the sales people is often overlooked, but it is essential because supporting the wire machine with incoming work is critical,” Mr. Cicchetti says.

He adds that a good plan includes a timeline and due dates, with lists of action items assigned to the individuals responsible for carrying them out. Recurring action items such as regular maintenance routines, supply replenishment and reordering of consumables and wear components should also be spelled out, with appropriate intervals clearly stated in each case.

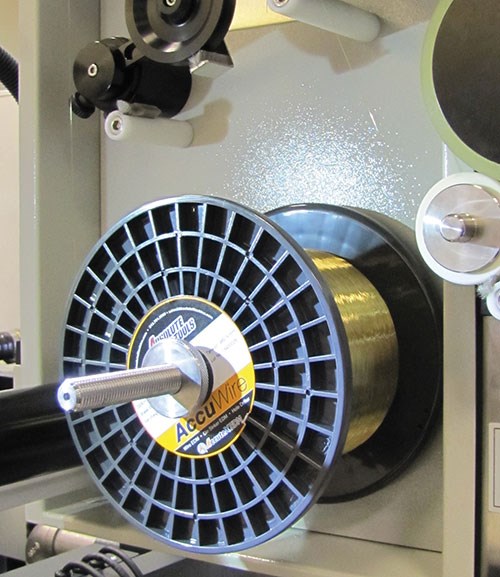

A good plan also identifies the capacities needed on the EDM unit, such as sufficient wire supply (spool size), long-lasting energizing pins (also called power feeds) and filter life (adequate to cover the intended period of operation, such as over a weekend. Likewise, the reliability of the wire threader and the adaptive features of the power supply unit for predictable cutting conditions should be evaluated for automated applications.

Get Everyone On Board—Especially Top Management

Mr. Cicchetti says that as soon as a shop begins planning for automated wire EDM, it should also get a firm commitment from top management. This means more than getting the general manager or shop owner to give an OK to the EDM department’s intention to run its wire machines in the unattended mode. It must be clear that unattended operation usually requires a change in “lifestyle” for many people in the shop, especially if this is the shop’s first experience with automation or unattended operation.

Managers at the top should expect new and different behavior on the shop floor and not be surprised by these changes.

“Commitment boils down to practical budgetary factors, too,” Mr. Cicchetti says. Investment in new tooling, optional equipment on the machine and training have to be expected and accepted, he says. Training is especially important. “If top managers balk at setting aside time and expenses for adequate training of operators, programmers and other shop positions, then there is no real commitment and the success of an automation initiative becomes uncertain,” he explains.

Planning for unattended operation and getting management commitment go hand in hand, Mr. Cicchetti goes on to say. “Selling management is more easily accomplished when it sees a solid plan emerging. Likewise, an EDM department can build a better plan when it has facts and figures from management,” he sums up.

Evaluate Your Workload

Mr. Cicchetti notes that a shop must understand the nature of its workload that is targeted for unattended wire EDM. “Shops tend to look at the gravy work first and that can be a trap. They think of the big blocks of steel that can be threaded one time, and will cut nonstop for 30 hours in a single shape. It’s easy to get unattended operation for those pieces,” he cautions.

It’s more important, he says, for a shop to be able to recognize groupings of workpieces such as similar stamping die details that can be set up in multiples and processed consecutively. Accommodating this kind of work forces a shop to address the need for appropriate tooling and setup procedures as well as programming capability. This also pushes a shop into the area where unattended operation provides the greatest cost reductions and time savings.

Similarly, a shop must be able to recognize the kind of work that does not lend itself to this approach. “Repair work and other jobs that are unpredictable or have a lot of unknowns are best excluded from the mix for unattended operation,” he says. If it requires craftsmanship and expert tweaking at the machine, or if features are not precisely dimensioned upon arrival, it is best to set it aside for manual operation, he advises.

Mr. Cicchetti points out that a thorough evaluation of a shop’s workload often leads to a challenge for the shop’s scheduler or scheduling system. The demanding manual jobs must be balanced with time to set up work that will fill the periods of unattended operation. Often this can be resolved by explaining the priorities to the scheduling department, Mr. Cicchetti says.

Tooling for Off-Line Setup

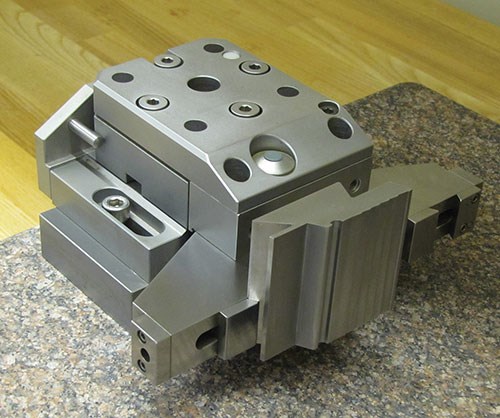

Mr. Cicchetti reports that a frequent point of resistance to unattended operation is the idea that a shop’s array of wire EDMed parts is too diverse for “production work.” The comment he often hears is, “All of our parts are different—different sizes, different profiles, different materials. Unattended will never work for us.” His response is to explain the importance of an appropriate approach to EDM tooling methods. “It’s a combination of having the right workholding elements and the habit of doing setups offline—that is, on a dedicated station away from the machine.”

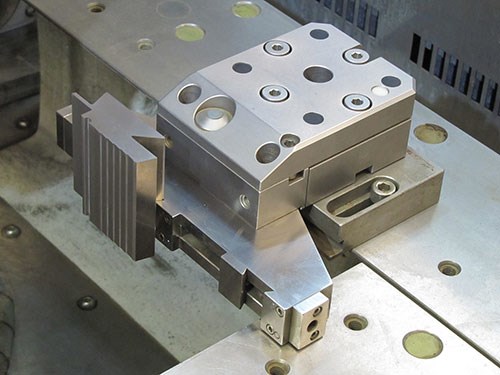

He defines the right workholding elements as those found in a high-quality integrated tooling system such as offered by System 3R, Erowa, Hirschmann and others. He offers this advice: “Regardless of the system you choose, it must be accurate, repeatable and durable. Don’t buy on price alone. Ask tooling suppliers about tooling packages that include the basic components to get started. Extra pieces can be added as needed. A shop with basic toolroom equipment can fabricate custom pieces, as well.”

Mr. Cicchetti recommends that the first tooling strategy a shop should implement to do more unattended operation is offline setup. “Essentially, this means having duplicate pallet receivers on a surface plate at the workbench and on the rails in the machine. Then it’s just a matter of mounting workpieces on fixtures or clamping devices that interface with a common pallet that can be transferred from the setup station to the identical receiver on the machine,” he explains. Fixtured parts can be aligned in three axes offline with a dial indicator and/or a height gage at the surface plate before moving.

The next step is to locate the parts on the offline station as well, he says. This entails measuring and recording part coordinates to be input at the machine. “A shop in the habit of using the pick-up function on the wire machine loses all the time that could be used for wire cutting,” he explains. Picking up the coordinates on the machine involves using the wire on the machine as a kind of sensor probe that touches off all the edges of the parts, a procedure that takes an average of about five minutes per part. Over a year’s time, the accumulated on-machine pickup time represents around 130 hours of lost wire cutting per machine, Mr. Cicchetti calculates. Offline setup and presetting win back that lost time.

Some shops, he adds, gain proficiency at offline setup and eventually reach a point in which having a robot and a part storage carrousel begin to make sense. This is not the ultimate goal for every shop, he notes. Likewise, a number of shops may legitimately discover that their work is not conducive to unattended operation, but he believes this number is very small. “Every shop with wire EDM owes it to itself to consider unattended operation earnestly before making that conclusion,” he says.

Reprocess the Process

One of the most difficult adjustments a shop has to make when implementing automated wire EDM is learning to process workpieces with unattended wire EDM in mind. This is a challenge to every level in the shop. Designers, programmers and machinists will have to change their habits. “This is the kind of change that is likely to create the most resistance, but it is also the most promising opportunity for a shop to reach new levels of teamwork and communication,” Mr. Cicchetti says. “I think a shop needs to tackle this adjustment with both realism and optimism.”

Mentioning a few of the most important processing changes a shop must embrace suffices to show the scope of this adjustment: Planning for the best use of automated wire EDM begins when ordering raw material. For example, blocks must include sufficient stock for the fixture to grip on.

Block preparation procedures must provide for slug management. The slug is the mass of material released when the wire tool path is complete. There has to be a strategy to hold the slug in place while the workpiece is being wire cut. Proper size and placement of start holes is one element in this strategy, too.

The order of additional machining operations or processes must be sequenced to be wire EDM friendly. For example, heat treating and grinding may require rethinking. When and what to inspect can change in order to facilitate wire cutting without the operator to catch and fix problems. This may mean simply getting into the habit of holding a block up to the light to check that start holes are present, go all the way through, and are not clogged with chips or debris.

Designing in a feature that becomes a common gripping surface for the standard modular components in an integrated tooling system is another thing to consider.

The Right Path to Programming

Many CAM systems offer modules for programming wire EDM. A shop planning for unattended operation should not assume that all wire modules support this mode of operation equally well. Mr. Cicchetti recommends that planners discuss the programming software requirements needed for automation with the machine supplier. The software should be capable of writing programs that utilize the wire machine’s features for automation.

Mr. Cicchetti explains that some wire machines provide on-board programming functions that can be applied on the shop floor to enhance the wire path generated by the offline programming system. For example, certain functions are designed to facilitate unattended operation. These may include a function that automatically adds stops at a specified distance along the wire path for slug retention. This function may also generate a program that automatically retraces the path to remove these stops in the proper sequence for safely releasing the slug. Generating the appropriate skim cuts may also be an automatic function. If the machine is not equipped with such on-board functions, the shop should be sure similar capability is provided by the offline programming software. For flexibility, the operator should be able to activate or deactivate the automatic functions at the machine, so switching between manual and unattended operation is easily accomplished.

In any case, programmers may need additional training to prepare programs that enable unattended operation.

Mr. Cicchetti also notes that it is important for the programming software or the machine control to provide an accurate estimate of cut time for each part program. The accuracy of this estimate depends on realistic values for the numerous variables in the wire EDM process. Reliable estimates are vital to scheduling and planning unattended operation. “There’s no point in setting up a machine to run overnight if the cumulative cut times are over or under the available hours,” he points out. “If you put a block in and you don’t know how long it’s going to take to cut the shape, you don’t know what will be done in the morning or what’s not going to be done.”

Run 5,000 Hours a Year

From experience at Absolute, Mr. Cicchetti believes that a shop with a well-planned and carefully implemented program for unattended operation should expect as many as 5,000 hours of productive cut time per machine per year in most applications. Achieving that level of utilization requires good discipline and strong shopfloor habits in combination with having the right machine with the right capabilities and options.

Finally, he urges shops to choose a wire machine supplier with experience in unattended operation. This supplier can be a key player in the planning and implementation stages. Automating the wire EDM process can help a shop succeed by reducing production costs and improving responsiveness, but achieving this success is not automatic, he says. “It takes planning, commitment, training and openness to change. Even having the best equipment in the world doesn’t change that fact,” he concludes.

Related Content

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More